BE Series Rubber Injection Molding Machine

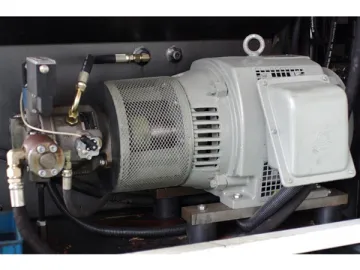

The BE series rubber injection molding machine is provided with 2 types of power systems. One is Taiwan Datong motor, the standard variable pump drive, and the other is the variable pump drive from Rexroth, both of which afford precise, energy-efficient and high-efficiency power for the whole hydraulic system. What’s more, the former is basically economical with 0.4-0.45 energy dissipation coefficient, suitable for the most of customers.

This rubber injection molding machine is also fitted with 2 types of injection units for your options. One is capable of vertical material storing and vertical injection for standard configuration, and the other enables horizontal material storing and vertical injection. So, you can choose one of them based on actual needs.

Doush supplies the rubber injection molding machine from 100T to 400T to satisfy the usage requirements of different customers. This equipment can be used to manufacture bushings, suspension mechanisms, damping blocks, engine mounting mechanisms, sealing elements, oil seals, door seals, insulated terminals and other products. It has been widely applied to the automobile industry, electric power industry, civil industry and other fields.

Parameters

| Clamping Unit | |||||||

| Machine type | BE100 | BE160 | BE250 | BE400 | BE560 | ||

| Clamping force | kN | 1000 | 1600(1700) | 2500(2800) | 4000(4450) | 5000(5500) | |

| Opening force | kN | 38 | 58 | 58 | 93 | 94 | |

| Opening stroke | kN | 450 | 500 | 500 | 600 | 650 | |

| Max. opening between heating plates | mm | 500 | 600 | 650 | 780 | 850 | |

| Clamping speed | mm/sec | 420 | 420 | 400 | 430 | 435 | |

| Opening speed | mm/sec | 450 | 290 | 467 | 290 | 450 | |

| Lifting stroke (Stretching/retracting force) | mm(kN) | 250(24.5/14.5) | 250(40/24.5) | 250(62.8/38) | 400(98/58) | 400(98/58) | |

| Injection Unit | |||||||

| Max. injection volume | cm3 | 500 | 1000 | 2000 | 3300 | 4500 | |

| Max. injection pressure | bar | 2000 | 2130 | 2000/2200 | 2000/2240 | 2080 | |

| Max. injection capacity | cm3/sec | 60 | 80 | 135 | 135 | 205 | |

| Screw diameter | mm | 27 | 32 | 42 | 52 | 62 | |

| Screw length diameter ratio | L:D | 10:1 | 10:1 | 10:1 | 10:1 | 10:1 | |

| Max. speed/torque of screw | rpm/Nm | 220/380 | 250/540 | 213/1250 | 237/1372 | 150/1940 | |

| Plasticizing capacity | cm3/min | 400 | 600 | 1000 | 2000 | 2200 | |

| Number of heating zones | 1 | 3 | 3 | 3 | 3 | ||

| Hydraulic Unit | |||||||

| System pressure | bar | 250(280) | 250(280) | 250(280) | 250(280) | 250(280) | |

| Max. pump capacity (1450rmp) | L/min | 41 | 41 | 65 | 65 | 103 | |

| Tank volume | L | 100 | 150 | 200 | 300 | 500 | |

| Electrical Equipment | |||||||

| Motor Power | kW | 15 | 15 | 22 | 22 | 30 | |

| Heating capacity of plates | kW | 10.8 | 9.9 | 15.9 | 25.2 | 30.2 | |

| Controller voltage | V | 24 | 24 | 24 | 24 | 24 | |

| * Excluding additional mould heating | |||||||

| Mould Mounting Dimensions (mm) | |||||||

| A | Locating ring size | 80 | 110 | 110 | 110 | 110 | |

| C | Nozzle inner diameter | 4 | 4 | 6 | 8 | 8 | |

| D | Max. nozzle diameter | 6 | 6 | 10 | 12 | 12 | |

| E | Min. mould height | 50 | 100 | 150 | 180 | 200 | |

| E1 | Max. mould height | 250 | 300 | 350 | 400 | 600 | |

| F | Clear distance of columns(W) | 525 | 590 | 720 | 830 | 950 | |

| G | Clear distance of columns(L) | 270 | 295 | 380 | 600 | 710 | |

| H | Heating plate width | 360(450) | 500(570) | 600(670) | 710(810) | 810(910) | |

| I | Heating plate Length | 500(600) | 550(650) | 650(750) | 800(1200) | 1100(1300) | |

| T-slot bolt (mm) | |||||||

| Upper and bottom ejector | M12 | M12 | M12 | M16 | M16 | ||

| Heating platen | M12 | M16 | M16 | M16 | M16 | ||

| Machine Dimensions (mm) | |||||||

| A | Total height | 2840 | 2900 | 3309 | 3627 | 3980 | |

| G | Total length | 2000 | 2700 | 2700 | 3100 | 3660 | |

| N | Total width | 1120 | 1150 | 1200 | 1400 | 1680 | |

| Weight | |||||||

| Standard machines | Kg | 4100 | 5800 | 7500 | 14000 | 20000 | |

Related Names

Rubber Injection Equipment | Rubber Processing Machinery | Plate Vulcanizing Machine

Links:https://www.globefindpro.com/products/80506.html

-

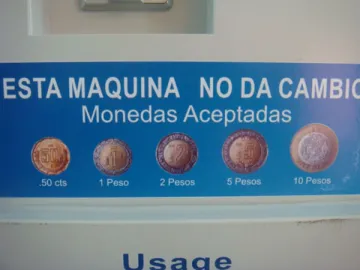

Water Vending Machine

Water Vending Machine

-

Bottle Labeling Machine

Bottle Labeling Machine

-

Mould for Anti-vibration Mount

Mould for Anti-vibration Mount

-

Bottle Decapper

Bottle Decapper

-

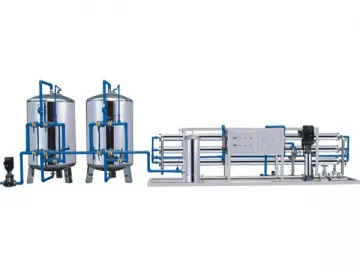

Industrial Reverse Osmosis System (15000LPH)

Industrial Reverse Osmosis System (15000LPH)

-

Ditch Cover

Ditch Cover

-

3 in 1 Automatic Bottle Filling Machine

3 in 1 Automatic Bottle Filling Machine

-

Industrial Reverse Osmosis System (20000LPH)

Industrial Reverse Osmosis System (20000LPH)

-

Industrial Reverse Osmosis System (700LPH)

Industrial Reverse Osmosis System (700LPH)

-

Auto Bottle Lifting Machine

Auto Bottle Lifting Machine

-

Industrial Reverse Osmosis System (5000LPH)

Industrial Reverse Osmosis System (5000LPH)

-

Shrink Wrap Machine

Shrink Wrap Machine