Bottle Labeling Machine

The bottle labeling machine can be used individually, or used with other equipment to form a complete bottling line. Shielded by a protective cover, it is extremely elegant, pretty, and safe. Its materials feeding system is adjustable. The bottle labeler has a high-speed electric eye that can accurately target the labels. Due to the standardization of the central molds, the bottle labeling machine allows for quick changing of bottles. A specially designed synchronous bottles separator makes sure the smooth, stable delivery of bottles.

In addition, this bottle labeling machine comes with a uniquely developed cutter which is adjustable. The cutter allows for smooth cutting surface. Its cutting blade is easy to replace. You can instantly dismantle the cutting blade without any tools. Needless to say, the bottle label applicator is regulated via a advanced control system and color touch screen. All the electric appliances of high standard ensure the smooth operation of the bottle labeling machine. Unlike the traditional labeler, this labelling machine can automatically target the labels on the accurate position of the bottles, and then cut the labels. As a shrink sleeve applicator, it uses steam to shrink the label snugly to the bottles.

Advantages

The bottle labeling machine makes the utmost of the photoelectric sensor. A color code electrical machine identifies the label cutting position, because of which the cutting error is controlled below 1mm. Since it uses steam to shrink the label snugly to the bottles, this bottle labeler requires less cost than the self-adhesive labeling machine does.

We design the molds of each labeling machine according to the bottle shapes. The bottle damage rate is thereby significantly decreased. Our bottle labeler applies an imported label shooting wheel which is extremely durable. The photoelectric design ensures the accurate label cutting.

With the frame made of 304 stainless steel, the bottle labeling machine is clean and beautiful. It operates stably, due to the application of Panasonic brand electric appliances.

Application

This bottle labeling machine wraps the plastic bottles with PVC labels. Because of the groove design of the plastic bottles, the labels can be fixed and shrunk to the suited position of the bottles.

Sales

The bottle labeller has been exported to Saudi Arabia, Yemen, Iraq, Libya, Liberia, Mali, Ghana, Nigeria, South Sudan, Cameroon, Gabon, Congo, Uganda, Ethiopia, Somalia, Kenya, Tanzania, Angola, and Zambia.

Parameters

| Model | ZYF-300M |

| Voltage | 1. Host machine: AC220V, 50/60HZ, 1. 5-2KW, single phase, or AC380V, 50/60HZ, 4KW 3 phasesSpare Host Machine: AC220V, 50/60HZ, 4KW, phases2. Shrinkage Furnace: AC380V, 50/60HZ 3 phases |

| Production Speed | Standard Label Length: 100mm, production speed varies with clients’ needs; standard speed is 100-500 bottles/min The shorter labels are, the faster the production speed will be. |

| Applicable Diameter of Bottle Body | Ф28mm~125mm |

| Applicable Length of Label | 30mm~250mm |

| Applicable Thickness of Label | 0.03mm~0.13mm |

| Applicable Materials of Label | PVC, PET, OPS |

| Size of Host Machine | L2100mm*W850mm*H2000mm |

| Steam Shrinking Oven | Steam consumption: 50Kg/H |

| Steam Pressure: 1Kg/cm2 | |

| The volume of the oven: L2300mm*W400mm*H1500mm |

Links:https://www.globefindpro.com/products/80508.html

-

Mould for Anti-vibration Mount

Mould for Anti-vibration Mount

-

Bottle Decapper

Bottle Decapper

-

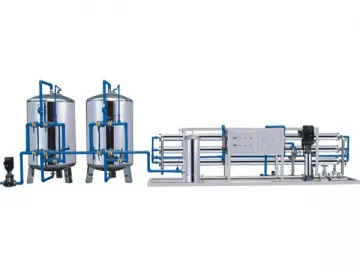

Industrial Reverse Osmosis System (15000LPH)

Industrial Reverse Osmosis System (15000LPH)

-

Ditch Cover

Ditch Cover

-

Circular Sawing Machine

Circular Sawing Machine

-

Composite Steel Gratings

Composite Steel Gratings

-

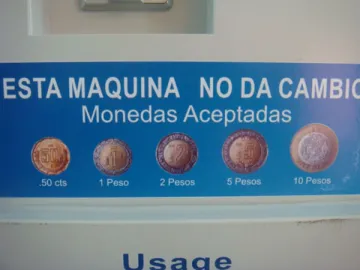

Water Vending Machine

Water Vending Machine

-

BE Series Rubber Injection Molding Machine

BE Series Rubber Injection Molding Machine

-

3 in 1 Automatic Bottle Filling Machine

3 in 1 Automatic Bottle Filling Machine

-

Industrial Reverse Osmosis System (20000LPH)

Industrial Reverse Osmosis System (20000LPH)

-

Industrial Reverse Osmosis System (700LPH)

Industrial Reverse Osmosis System (700LPH)

-

Auto Bottle Lifting Machine

Auto Bottle Lifting Machine