Piezoresistive Grating Welding Machine

Grating Welding Machine

GZY-II-2100 Piezoresistive

Grating Welding Machine

Our piezoresistive grating welding machine varies in two models, namely GZY-II-1500 and GZY-II-2100. It is featured by unique structure, good quality, easy maintenance, high output, etc.

1. Good Welding Quality

The piezoresistive grating welding equipment applies the electrode automatic balancing technology, for which we have obtained a patent and the patent number is ZL2005 2 0084716.0. This technology allows for the full use of electric energy, so each welding point is secure and solid.

2. Energy Saving

With the optimized transformer and advanced rectifier elements, our welding machinery is small in size, compact in structure. In addition, the transformer is directly connected to the secondary power transmission part. The power consumption is thereby lowered.

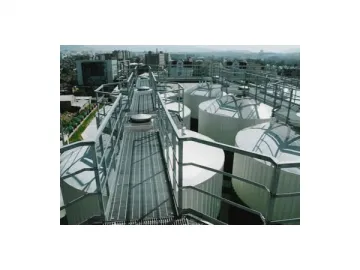

3. Wide Applicable Range

It not only can be used for the welding Q235, Q215, Q195, or other common carbon steel, but also for the welding of 304SS or other stainless steel.

4. Fast Welding Speed

Since high-power hydraulic pressure station is matched with energy-efficient transformer rectifier components, the welding machine works speedily. A MITSUBISHI controller is configured. We have optimized the operational procedures for several times, which help speed up the production efficiency. Each hour, it can make 8~12 pieces of grating panels that are 1m wide and 6m long. The production speed is fast when flat steel is thinner.

5. Compact Structure and Small Occupation

The whole welding production line has been optimized. Its compact structure helps save floor coverage and space.

6. Modular Design Contributing to Convenient Maintenance and Equipment Updating

The hoisting, dragging, crossbar feeding parts are independent units, allowing for easy maintenance and updating.

7. The self elevating platform prevents abrasion.

We have obtained more than a dozen patents for the welding equipment design.

Parameters

| Power supply | 380V 50HZ (or according to client’s requirement) |

| Capacity of power transformer | 1000KVA |

| Maximum pressure | 100 tons |

| Installed capacity of welding transformer | 1500KVA |

| Maximum nominal weld width | 1000mm |

| Weld length | 2000~7000mm |

| Thickness of flat steel | 2.7~6mm (including flat steel thickness deviation) |

| Width of flat steel | 20~65 |

| Center distance of flat steel | regular 30mm, or 40mm (also according to center distance of client’s required providing comb-shaped clamp) |

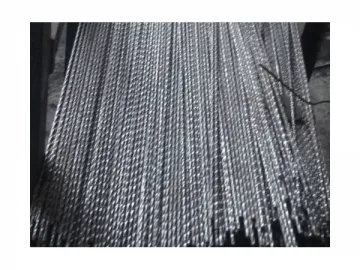

| Twist square steel | 5×5, 6×6 |

| Center distance of twist square steel | regular 50mm, or 100 mm, (also according to center distance of client’s required providing comb-shaped clamp) |

| Numbers of pressure weld cross bar each time | 2 cross bars per time. |

| Pressure welding time | 0.5~5 seconds (it takes longer time when welding larger sizes of steel); pressure welding cycle: 4~10 seconds; when center distance of flat steel is 30mm, 68 welding spots from pressure welding each time; when center distance of flat steel is 40mm, 52 welding spots from pressure welding each time. When center distance of twist square steel is 100mm, the speed of producing steel grating is 1000~2500mm/minute |

| Overall Dimensions | maximum height 4m, maximum width 5m, and maximum length 30m; |

Links:https://www.globefindpro.com/products/80524.html