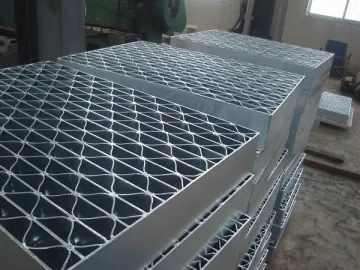

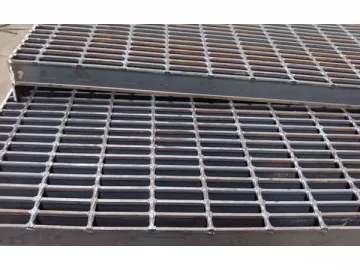

Steel Mesh Gratings

The steel mesh grating is our patented product developed according to the new national safety requirements. It is manufactured by the world-class, energy-saving grating welding machine developed by ourselves.

Manufacturing Process

Firstly press the orderly arranged twisted square steels into flat steel. During the welding process, a steel rod will be placed between the flat steels, thus to get a steel mesh grating with solid welding joints and square holes.

According to the side surface shape of flat steel, the steel product is divided into flat type and tooth shaped type. It comes with many different specifications. Based on the application environment, its surface can be specially treated.

Advantages

1. The steel mesh grating comes with higher security coefficient, since its clear interval is below 20mm. It meets the national safety requirements.

2. Compared to other steel grating products of same loading and deflection, it saves 19%-36% materials.

3. Before out of factory, it has been treated with hot-dip galvanizing. It perfectly resists impact, and withstands heavy loads.

4. Due to the standardized design, the steel structure lets in air and light. It looks modern and elegant.

5. Light in weight, it is easy to install.

6. This product is explosion proof and anti-skid. It has good heat dissipation

Application

1. Used to make platforms for ships, oil factory, car washing factory, etc.

2. Used to make floor grating for bridges, parking lots, etc.

3. Used to make steel handrails, ditch cover, drain cover, etc.

Links:https://www.globefindpro.com/products/80541.html

-

Custom Made Gratings

Custom Made Gratings

-

SY-2000 Horizontal Concrete Pipe Making Machine

SY-2000 Horizontal Concrete Pipe Making Machine

-

Heavy Duty Gratings

Heavy Duty Gratings

-

Wave Edge Rules

Wave Edge Rules

-

Positive PS Plate

Positive PS Plate

-

QT8-15 Fully Automatic Concrete Block Production Line

QT8-15 Fully Automatic Concrete Block Production Line

-

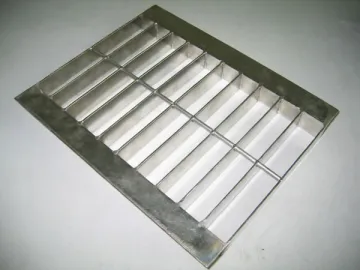

Standard Gratings

Standard Gratings

-

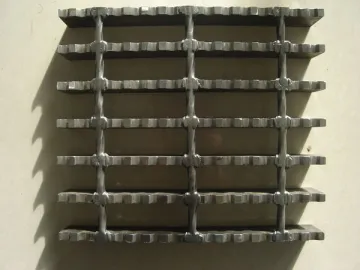

Press-locked Gratings

Press-locked Gratings

-

Stainless Steel Gratings, Aluminum Grating

Stainless Steel Gratings, Aluminum Grating

-

QT4-15A Fully-Automatic Concrete Block Production Line

QT4-15A Fully-Automatic Concrete Block Production Line

-

I Bar Gratings

I Bar Gratings

-

Floor Gratings for Platform

Floor Gratings for Platform