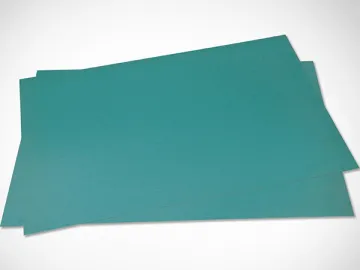

Positive PS Plate

PS plate is a kind of lithographic or letterpress plate coated with photosensitive film. It could be used for printing anytime.

Unique grain producing technique is applied to the manufacturing process to achieve the even distribution of the grain and the multi-grain layer structure. The multi-grain layer technique, developed by Fujifilm, allows different grains including big grain, medium grain and small grain to coexist on the plate. With different sizes of grains, the run length of the plate is extended, and unwanted dots seldom show up. The other technologies we adopted include:

1. Unique sealing process on the oxidized layer of thealuminum, thus the hydrophily of the non-image area is enhanced;

2. Advanced photosensitive technology, which gives high sensitivity, great reproduction of small dots, high resolution and long run length;

3. Leading rough surface air vacuum technique, which can pump out the air between the film and the PS plate faster, and thus the plate making process is simplified.

The positive PS plate is suitable for the printing of business card, newspaper, magazine, package, book, business form and stationery. The parameters of the plate and its developing process are as follows:

Specifications:

Type: positive PS plate

Coating color: green

Substrate material: electrochemicalgrained anodic-oxidation aluminium with hydrophilic coat.

Thickness: 0.15 ~ 0.30 mm

Spectral sensitivity: 380 ~ 420 nm

Exposure energy: 160 ~ 180 MJ/cm2

Resolution: 2% ~ 98% at 175 lpi

Run length: 100000

Safe light: yellow light

Shelf life: 24month (25℃ and 60% RH)

Developing:

Dilution ratio: 1:6~1:8

Developer temperature: 20~30C

Duration: 20~40s

Related Names

Offset Printing Plate | Flexographic Printing Plates | Lithographic Printing Supplies

Links:https://www.globefindpro.com/products/80547.html

-

QT8-15 Fully Automatic Concrete Block Production Line

QT8-15 Fully Automatic Concrete Block Production Line

-

PLD1200 Three-Hopper Concrete Batching Plant

PLD1200 Three-Hopper Concrete Batching Plant

-

QT10-15 Fully Automatic Concrete Block Production Line

QT10-15 Fully Automatic Concrete Block Production Line

-

SY-3000 Curb Stone Making Machine

SY-3000 Curb Stone Making Machine

-

QT6-15B Fully Automatic Concrete Block Production Line

QT6-15B Fully Automatic Concrete Block Production Line

-

QM4-45 Diesel Engine Block Making Machine

QM4-45 Diesel Engine Block Making Machine

-

Wave Edge Rules

Wave Edge Rules

-

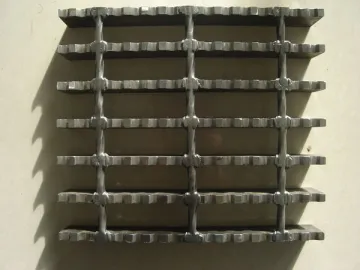

Heavy Duty Gratings

Heavy Duty Gratings

-

SY-2000 Horizontal Concrete Pipe Making Machine

SY-2000 Horizontal Concrete Pipe Making Machine

-

Custom Made Gratings

Custom Made Gratings

-

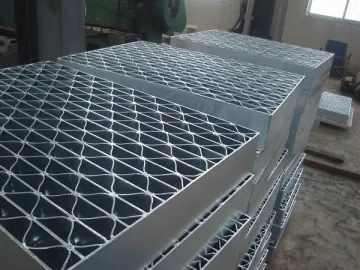

Steel Mesh Gratings

Steel Mesh Gratings

-

Standard Gratings

Standard Gratings