QT10-15 Fully Automatic Concrete Block Production Line

The QT10-15 fully automatic concrete block production line enjoys the output of 42240 pieces every 8 hours and the molding cycle of 15 seconds. Controlled by the PLC, it has several functions, including computer operation, random signal analysis, failure diagnosis and material parameter setting. Therefore, it is easy to operate.

Its hydraulic vibration system employs an electro-hydraulic proportional valve to control the hydraulic motor, which realizes feeding through low-frequency vibration and molding through high-frequency vibration. In addition, a unique pallet supporting device is placed 1-1.5mm lower than the vibration table. When the concrete block production line works, the table will descend and supported by the device, so as to reduce the pressure on the vibrating case and increase vibrating force. In this way, the finished blocks may come with high compactness and accurate height whose error is controlled within 1mm. Its material feeding system is fitted with rows of mixing forks. The feeding box can move front and back quickly to fill in the molding flask efficiently.

| Productive capacity | 400x200x200mm: 19200 PCS /8hour 400x150x200mm: 26800 PCS/8hour 400x100x200mm: 42240 PCS/8hour |

| Power | 50.88 kw |

| Overall size | 7500X2500X3020 mm |

| Cycle | 15 s |

| Pallet size | 1220x900x25mm |

| Vibration force | 100KN |

| Vibration frequency | 4000-4800/Minute |

| Nominal pressure | 30Mpa |

| Total weight | 15000kg |

| Power source | 380v/50HZ |

Related Names

Hydraulic Block Making Machine | Engineering Machinery | Building Material Production Line

Links:https://www.globefindpro.com/products/80551.html

-

SY-3000 Curb Stone Making Machine

SY-3000 Curb Stone Making Machine

-

QT6-15B Fully Automatic Concrete Block Production Line

QT6-15B Fully Automatic Concrete Block Production Line

-

QM4-45 Diesel Engine Block Making Machine

QM4-45 Diesel Engine Block Making Machine

-

SY7502 Hydraulic Interlocking Paver Making Machine

SY7502 Hydraulic Interlocking Paver Making Machine

-

QT4-15B Fully Automatic Concrete Block Production Line

QT4-15B Fully Automatic Concrete Block Production Line

-

SY1-10 Hydraulic Interlocking Brick Making Machine

SY1-10 Hydraulic Interlocking Brick Making Machine

-

PLD1200 Three-Hopper Concrete Batching Plant

PLD1200 Three-Hopper Concrete Batching Plant

-

QT8-15 Fully Automatic Concrete Block Production Line

QT8-15 Fully Automatic Concrete Block Production Line

-

Positive PS Plate

Positive PS Plate

-

Wave Edge Rules

Wave Edge Rules

-

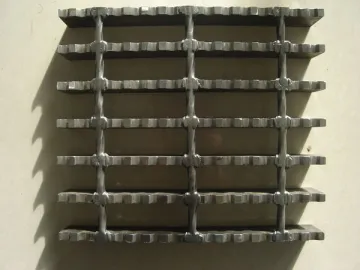

Heavy Duty Gratings

Heavy Duty Gratings

-

SY-2000 Horizontal Concrete Pipe Making Machine

SY-2000 Horizontal Concrete Pipe Making Machine