QM1-40 Manual Interlocking Brick Making Machine

As an environment-friendly block machine, the QM1-40 manual interlocking brick making machine is able to manufacture all sorts of interlocking bricks, U-shaped bricks, half bricks, roof tiles, etc. Made from coal gangue, fly ash and other industrial residues, the produced bricks come with smooth surface and high ruggedness. Therefore, using these ecological bricks helps to reduce environmental pollution, and save clay as well as bunker coal.

Features

1. Carved by a full-automatic numerical control machine, its moulds are proud of high quality, long working life, neat appearance and accurate dimension.

2. The interlocking brick making machine can be equipped with diverse moulds in accordance with your demands, so as to produce bricks with different dimensions and shapes.

3. Usually, the materials of interlocking bricks are cement, soil and water. The bricks can be made through mixing and compressing procedures. Setting up a house with these bricks may lower the total cost to 60%. Why not build one for yourself ?

4. You may pile up the finished bricks for drying, which requires a small occupied area. The manual brick machine is a satisfactory substitute for a traditional hydraulic machine.

| Overall size | 600x300x1000mm |

| Cycle | 60s |

| Weight | 120kg |

| Material | 1. Soil 2. Cement and soil |

Links:https://www.globefindpro.com/products/80575.html

-

QMY4-45 Block Making Machine

QMY4-45 Block Making Machine

-

Motor Rotor

Motor Rotor

-

Spring Punch

Spring Punch

-

Wind Turbine Motor Rotor Core

Wind Turbine Motor Rotor Core

-

Windscreen Wiper Motor Stator Core

Windscreen Wiper Motor Stator Core

-

Air Conditioner Motor Stator Core

Air Conditioner Motor Stator Core

-

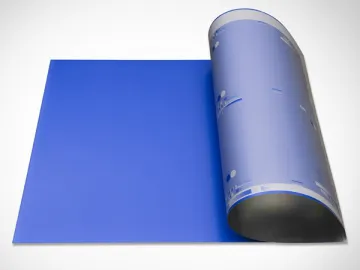

Thermal CTP Plate

Thermal CTP Plate

-

Special Label Rules

Special Label Rules

-

Long Centre Bevel Cutting Rules

Long Centre Bevel Cutting Rules

-

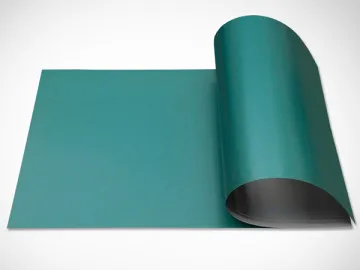

CTCP Plate

CTCP Plate

-

SY1-20 Hydraulic Interlocking Brick Making Machine

SY1-20 Hydraulic Interlocking Brick Making Machine

-

Label Perforating Rules

Label Perforating Rules