CIL-SP-398 Multi-roll Toilet Paper Packaging Machine

The CIL-SP-398 multi-roll toilet paper packaging machine can automatically pack 4, 6, 8, 10 or 12 toilet paper rolls in one bag, and one machine is available with three of the five packing modes for customers’ choice.

Functions and Features

1. This toilet paper multi-roll packing machine is user-friendly, and you can independently operate it after one or two days training.

2. With high automaticity and stability, this equipment is widely used by paper product factories and featured by packing smoothness and high efficiency.

3. Customized or non-standard toilet paper multiple rolls packing machine is available.

4. There are holes on the top of the plastic bag for convenient handling.

5. Through adopting servo system and PLC, our multi-roll toilet paper packaging machine realizes automatic reset, packing, sealing and cutting.

6. The man-machine interaction control system with touch screen enables parameter and fault display. Meanwhile, the fault alarm and tracking system make for fast fault recovery.

7. Photoelectric detecting device, servo drive, pneumatic element, bearing tool and other components are introduced from well-known foreign brands.

8. This multi-roll toilet paper packaging machine can be configured with a cutting device.

Main Technical Parameters

1. Power

Main motor: 2KW

Conveyor: 1.5KW (380V, 50Hz)

Heating unit: 2KW (380V, 50Hz)

2. Production speed: 60-100 rolls/minute

3. Specification of plastic film: Ф500×760mm

4. Overall dimension: 3.0×1.1×1.2m (L×W×H)

5. Weight: About 2.0T

Links:https://www.globefindpro.com/products/80769.html

-

Chrome Finish SMD 4200K LED Spotlight with Round Crystal Glass Shade

Chrome Finish SMD 4200K LED Spotlight with Round Crystal Glass Shade

-

Energy Saving Illuminated Bathroom Mirrors

Energy Saving Illuminated Bathroom Mirrors

-

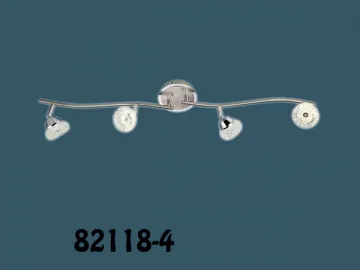

Satin Nickel and Chrome Finish 4200K LED Spotlight with Crystal Glass Shade

Satin Nickel and Chrome Finish 4200K LED Spotlight with Crystal Glass Shade

-

CIL-SP-D Kitchen Towel Rewinder

CIL-SP-D Kitchen Towel Rewinder

-

CIL-AS-699 Paper Handkerchief Packaging Line

CIL-AS-699 Paper Handkerchief Packaging Line

-

CIL-ZH-15 N.V Fold Towel Paper Packaging Machine

CIL-ZH-15 N.V Fold Towel Paper Packaging Machine

-

Satin Nickel and Chrome Finish LED Spotlight with Round Base

Satin Nickel and Chrome Finish LED Spotlight with Round Base

-

LED High Bay Lights

LED High Bay Lights

-

CCFL Half Spiral Bulb

CCFL Half Spiral Bulb

-

Induction Tunnel Lamp

Induction Tunnel Lamp

-

LED Backlit Bathroom Mirrors

LED Backlit Bathroom Mirrors

-

LED Spotlight

LED Spotlight