CIL-SP Toilet Paper Rewinder

Introduction

Capable of raw paper perforating, rewinding and cutting, the CIL-SP toilet paper rewinder can be used to make various specifications of toilet paper with high neatness and uniform rewinding tension. The entire machine is featured by compact structure, stable operation, easy control, low power consumption, small floor space (8.4 square meters) and high production efficiency (100m/min.), ideal for paper product processing.

This toilet paper rewinding and perforating machine is suitable for processing the raw paper of 1.2 meters (92 type) and 1.7 meters (75 type). It is mainly constituted by paper stand, conveying unit, embossing unit, perforating unit, rolling unit, electronic control unit, and cutting system. Production processes contain unwinding, embossing, perforating, winding and cutting.

This toilet paper rewinder is classified into two types, i.e. the ordinary type and the point-to-point type. The former is equipped with an embossing unit serviceable for two layers of paper, and the latter is outfitted with two embossing units respectively working for two layers of paper.

Features

1. This toilet paper machine enables invariable tension control for paper unwinding, fit for both top and low grade raw paper production.

2. The high-precision spiral cutter features low noise and distinct perforation.

3. Based on actual need, single-color or two-color printing press can be configured to obtain bright-colored paper.

4. This toilet paper rewinder can also be equipped with two sets of embossing device if needed.

Main Technical Parameters

| Model | 1092 | 1575 | 2000 | 2200 | 2400 | 2600 |

| Width of raw paper (mm) | 1200 | 1750 | 1950 | 2150 | 2350 | 2550 |

| Diameter of finished product | ¢60-150mm (The tightness is adjustable.) | |||||

| Core diameter of finished paper | ¢20-50 | |||||

| Diameter of raw paper | 1200mm (It can be customized.) | |||||

| Core diameter of raw paper | ¢76.2mm | |||||

| Perforation pitch | 3 cutters, 100-150mm (Other specifications should be specified.) | |||||

| Winding speed | 100-150m/min. | |||||

| Unwinding stand | 2 layers (If 3 layers are needed, please tell us.) | |||||

| Pneumatic system | Pressure: 5kg/cm2Pa (Prepared by customers) | |||||

| Power | 3-7.5KW | |||||

| Overall Dimension (L×W×H) | 4900×2700×1500-4900×4050×1500mm | |||||

| Weight | 2-4.5T | |||||

| Embossment | Single-side embossing, two-side embossing, steel-to-steel embossing (depending on actual needs) | |||||

| Bottom roller for embossment | Felt roller, wool roller, rubber roller (depending on actual needs) | |||||

| Remark | Custom-made machines are available including non-standard ones. | |||||

Links:https://www.globefindpro.com/products/80785.html

-

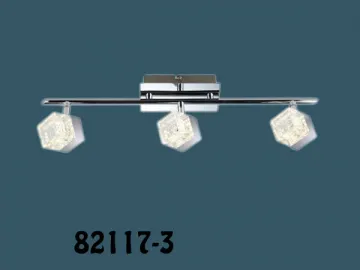

Chrome Finish LED Spotlights with Crystal Glass Shade

Chrome Finish LED Spotlights with Crystal Glass Shade

-

CIL-AS-288 Automatic V-folded Towel Paper Converting Machine

CIL-AS-288 Automatic V-folded Towel Paper Converting Machine

-

Illuminated Makeup Mirrors

Illuminated Makeup Mirrors

-

Illuminated Mirror Bathroom Cabinets

Illuminated Mirror Bathroom Cabinets

-

CIL-SP-A-C Automatic Single Roll Toilet Paper Production Line

CIL-SP-A-C Automatic Single Roll Toilet Paper Production Line

-

CIL-SP-4525 Semi-automatic Seal and Shrink Wrap Machine

CIL-SP-4525 Semi-automatic Seal and Shrink Wrap Machine

-

CIL-QQ-286 Automatic Coffee Filter Bag Converting Machine

CIL-QQ-286 Automatic Coffee Filter Bag Converting Machine

-

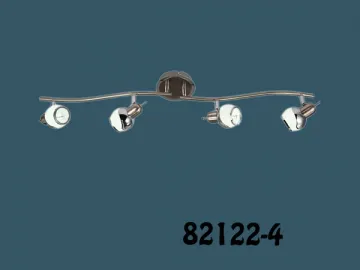

Satin Nickel and Chrome Finish 6200K LED Spotlight with Opal Glass Shade

Satin Nickel and Chrome Finish 6200K LED Spotlight with Opal Glass Shade

-

CIL-SP-280 Kitchen Roll Log Saw Cutting Machine

CIL-SP-280 Kitchen Roll Log Saw Cutting Machine

-

CIL-WW-B Paper Slitter Rewinder

CIL-WW-B Paper Slitter Rewinder

-

CIL-NP-35 Napkin Packaging Machine

CIL-NP-35 Napkin Packaging Machine

-

CIL-FT-258 Automatic Paper Packaging Machine

CIL-FT-258 Automatic Paper Packaging Machine