CIL-SP-A-C Automatic Single Roll Toilet Paper Production Line

The CIL-SP-A-C automatic single roll toilet paper production line is incorporated by three standalone devices, including the high-speed toilet paper rewinder, cutting machine and the single-roll toilet paper packaging machine.

The paper roll rewound by rewinder will be automatically conveyed to the feeding tailstock of large rotary cutting machine, the internal cutters of which will cut the paper roll into that with requested length. Then, the paper roll will be conveyed to the packaging machine for packaging, sealing and cutting. Gusset insert can be performed during end sealing to make packing film more fit the paper roll.

The automatic single roll toilet paper production line is absolutely your best choice.

Technical Parameters

| Width of raw paper | 1500-2750mm |

| Diameter of raw paper | Max. Φ1500mm |

| Inner diameter of raw paper core | Φ76.2mm |

| Raw paper | 1or 2 layers, 14-20g |

| Inner diameter of finished paper core | Φ25-80mm |

| Packing speed (bags/min.) | 35-120 |

| Dimension of roll paper (mm) | Diameter:≥100-200, length: 85-225 |

| Material of packing film | PVC, POF |

| Air compression (MPa) | 1 |

| Installed power | 7.5-17KW (380V, 50Hz) |

| Remark | Custom-made machines are available including non-standard ones. |

Core changing, rewinding, glue spraying and sealing can be performed without machine halt. Meanwhile, automatic speed reduction and speeding up are available during paper core pipe changing.

Core pipes won’t readily fall off since this automatic

It adopts PLC for automatic production control, including reset, cutting and the adjustment of cutting length and cycle, easy for operation.

This roll paper cutting machine is configured with man-machine interaction control system with touch screen for parameter and fault display.

Thanks to variable frequency inverter, packing length and finished bag length are controlled in stepless way and within a wide adjustable range.

This toilet paper single roll packing machine is capable of automatic product arrangement

Single-roll Toilet Paper Production Line | Single Roll Toilet Paper Making Machine | Single Roll Toilet Paper Manufacturing

Links:https://www.globefindpro.com/products/80790.html

-

CIL-SP-4525 Semi-automatic Seal and Shrink Wrap Machine

CIL-SP-4525 Semi-automatic Seal and Shrink Wrap Machine

-

CIL-WW-A Paper Slitter Rewinder

CIL-WW-A Paper Slitter Rewinder

-

CIL-AQ-291 Automatic Paper Toilet Seat Cover Converting Machine

CIL-AQ-291 Automatic Paper Toilet Seat Cover Converting Machine

-

CIL-RC-A Automatic Paper Roll Core Making Machine

CIL-RC-A Automatic Paper Roll Core Making Machine

-

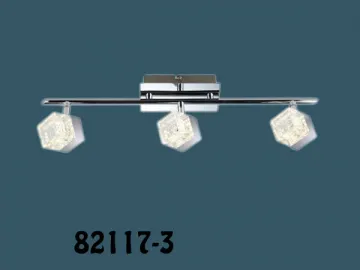

Matt Nickel and Chrome Finish LED Spotlight with Crystal Glass Shade

Matt Nickel and Chrome Finish LED Spotlight with Crystal Glass Shade

-

CIL-QQ-285 Automatic Cigarette Rolling Paper Converting Machine

CIL-QQ-285 Automatic Cigarette Rolling Paper Converting Machine

-

Illuminated Mirror Bathroom Cabinets

Illuminated Mirror Bathroom Cabinets

-

Illuminated Makeup Mirrors

Illuminated Makeup Mirrors

-

CIL-AS-288 Automatic V-folded Towel Paper Converting Machine

CIL-AS-288 Automatic V-folded Towel Paper Converting Machine

-

Chrome Finish LED Spotlights with Crystal Glass Shade

Chrome Finish LED Spotlights with Crystal Glass Shade

-

CIL-SP Toilet Paper Rewinder

CIL-SP Toilet Paper Rewinder

-

CIL-QQ-286 Automatic Coffee Filter Bag Converting Machine

CIL-QQ-286 Automatic Coffee Filter Bag Converting Machine