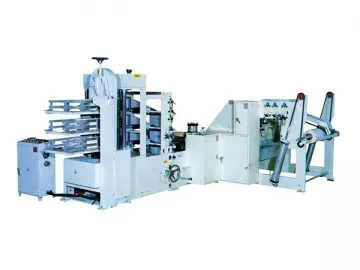

CIL-BD-A Baby Diaper Production Line

Introduction

1. Designed on the basis of same model machines from both home and abroad, the CIL-BD-A baby diaper production line enjoys the advantages including fully functioning, steady performance, and easy operation.

2. It can produce economic products and high-grade products. Just after changing a few parts, this production line can produce L, M, S and XL baby diapers.

Functions and Features

1. CIL-BD-A baby diaper production line applies a big web wheel to release cotton core.

2. All its critical parts are manufactured with special materials. The main standard configurations are of international renowned brands. So, the baby diaper equipment is durable.

3. A saw type fiber dissolution machine is used to smash treated, semi-treated, or untreated pulp.

4. The frequency converting control is used for cotton pulp feeding, and the feeding amount is displayed via a touch screen. The pulp feeding amount is automatically adjusted according to the production speed.

5. After the formation of the arc sides, the baby diapers will be folded vertically, and then conveyed in a line for convenient package.

6. The front, left and right waist tapes of baby diapers produced by this diapers making machine, are accurately and firmly.

7. This baby diaper production line adopts the adsorption conveying method for the raw materials. The guide bar type conveyer belt can avoid the excursion caused by temperature variations.

Parameters

| Type | CIL-BD-150A | CIL-BD-300A |

| Designed Production Speed | 150pcs/min | 300pcs/min |

| Stable Production speed | 100-120pcs/min ( take M size as sample) | 200-250pcs/min (take M size as sample) |

| Specification | XL, L, M, S | XL, L, M, S |

| Power | About 90Kw(excluding adhesive applicator) | About 110Kw(excluding adhesive applicator) |

| Power Supply | 380V/50HZ | 380V/50HZ |

| Rejection Ratio | ≤2% (Excluding the conditions of adhesive applicator malfunction and material feeding) | ≤2% (Excluding the conditions of adhesive applicator malfunction and material feeding) |

| Size of Machine | (L×W×H): about 18M×1.5M×2.2M | (L×W×H): about 20M×2.2M×2.8M |

| Weight | About 30T | About 35T |

| Remark | We can customize the machine according to the clients' request. | |

Links:https://www.globefindpro.com/products/80814.html

-

CIL-FT-602 Automatic Soft Facial Tissue Packaging Machine

CIL-FT-602 Automatic Soft Facial Tissue Packaging Machine

-

CIL-NP (FT)-115 Semi-automatic Napkin Packaging Machine

CIL-NP (FT)-115 Semi-automatic Napkin Packaging Machine

-

CIL-BD-C Semi-servo Baby Diaper Production Line

CIL-BD-C Semi-servo Baby Diaper Production Line

-

CIL-FT-228 Automatic Facial Tissue Packaging Machine

CIL-FT-228 Automatic Facial Tissue Packaging Machine

-

CIL-FT-A-D Automatic Facial Tissue Production Line

CIL-FT-A-D Automatic Facial Tissue Production Line

-

CIL-SN-500B Sanitary Napkin Production Line

CIL-SN-500B Sanitary Napkin Production Line

-

CIL-AS-301-2 Semi-automatic Paper Handkerchief Packaging Machine

CIL-AS-301-2 Semi-automatic Paper Handkerchief Packaging Machine

-

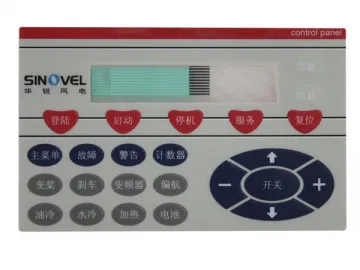

Membrane Switch

Membrane Switch

-

CIL-NP-7000A (180-500) Automatic Folded Napkin Converting Machine

CIL-NP-7000A (180-500) Automatic Folded Napkin Converting Machine

-

CIL-NP-7000K300-500-3 High Speed Napkin Converting Machine

CIL-NP-7000K300-500-3 High Speed Napkin Converting Machine

-

CIL-SP-300 Paper Roll Slitter Rewinder

CIL-SP-300 Paper Roll Slitter Rewinder

-

CIL-NP-AP Paper Coaster Converting Machine

CIL-NP-AP Paper Coaster Converting Machine