CIL-BD-C Semi-servo Baby Diaper Production Line

The CIL-BD-C semi-servo baby diaper production line comes with two models such as CIL-BD-300C and CIL-BD-400C. CIL-BD-300C applies the servodrive for cotton cutting, frontal tape, guide layer, side sticker, PU, forming cutting, three-folding, etc. You don't have to replace the driving part when you want to produce different size diapers. Driving system of CIL-BD-400C is composed of a servo motor, right-angle gear box, universal shaft, gear wheel, and a circular arc tooth synchronous belt. The right-angle gear box is equipped with a spiral bevel gear.

Functions and Features

1. The semi-servo baby diaper production line has a human-computer interface, allowing for the user-friendly operation. You can freely change the parameters required for the production at any time. With the human-computer interface, users can record and find all the production and alarming data.

2. It has a three-dimensional LYCRA elastic un-winding device which can be easily replaced. The LYCRA materials will be combined with waterproof non-woven fabrics to provide protection for baby legs.

3. The baby diaper making equipment employs an imported flat belt that is driven by an electric motor. Such flat belt can be automatically adjusted in accordance with the friction coefficient between low-speed and high-speed belts, thereby maintaining the uniform production speed of the whole production line.

4. Toilet papers are used to wrap pulp, so that the cotton core breakage can be prevented with effect.

5. The semi-servo baby diaper production line has an twin-screw type SAP adding device used for polymer mixed wood pulp distributing. This device is adjustable according to the engine speed. Additionally, the pulp adding amount is displayed and adjusted via a touch screen.

6. Front left and right waist tapes can be designed as per client's request. A big web wheel is used to release cotton.

7. CIL-BD-C diaper production machine has a sensor to automatically inspect and remove water products that are caused by feeding materials. It stops working automatically when the material is broken.

Parameters

| Type | CIL-BD-300C | CIL-BD-400C |

| Designed Production Speed | 300pcs/min | 400pcs/min |

| Stable Production Speed | 200-250pcs/min (take M size as sample) | 300-350pcs/min (take M size as sample) |

| Specification | XL,L,M,S | XL,L,M,S |

| Power | About 130Kw(Excluding gluing machine) | About 180Kw(Excluding gluing machine) |

| Power Supply | 380V/50HZ | 380V/50HZ |

| Rejection Ratio | ≤2% (Excluding the conditions of adhesive applicator malfunction and material feeding) | ≤2% (Excluding the conditions of adhesive applicator malfunction and material feeding) |

| Size of Machine | (L×W×H):about 20M×2.2M×2.9M | (L×W×H):about 20M×2.2M×2.9M |

| Weight | About 35T | About 40T |

| Remark | We can customize the machine according to the clients' request. | |

Links:https://www.globefindpro.com/products/80817.html

-

CIL-FT-228 Automatic Facial Tissue Packaging Machine

CIL-FT-228 Automatic Facial Tissue Packaging Machine

-

CIL-FT-A-D Automatic Facial Tissue Production Line

CIL-FT-A-D Automatic Facial Tissue Production Line

-

CIL-SN-500B Sanitary Napkin Production Line

CIL-SN-500B Sanitary Napkin Production Line

-

CIL-SN-400A Sanitary Napkin Production Line

CIL-SN-400A Sanitary Napkin Production Line

-

CIL-SP-A Automatic Kitchen Towel Rewinder

CIL-SP-A Automatic Kitchen Towel Rewinder

-

CIL-AS-288 Automatic Three-fold Towel Paper Converting Machine

CIL-AS-288 Automatic Three-fold Towel Paper Converting Machine

-

CIL-NP (FT)-115 Semi-automatic Napkin Packaging Machine

CIL-NP (FT)-115 Semi-automatic Napkin Packaging Machine

-

CIL-FT-602 Automatic Soft Facial Tissue Packaging Machine

CIL-FT-602 Automatic Soft Facial Tissue Packaging Machine

-

CIL-BD-A Baby Diaper Production Line

CIL-BD-A Baby Diaper Production Line

-

CIL-AS-301-2 Semi-automatic Paper Handkerchief Packaging Machine

CIL-AS-301-2 Semi-automatic Paper Handkerchief Packaging Machine

-

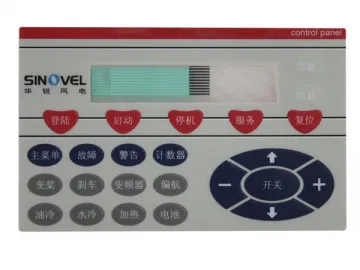

Membrane Switch

Membrane Switch

-

CIL-NP-7000A (180-500) Automatic Folded Napkin Converting Machine

CIL-NP-7000A (180-500) Automatic Folded Napkin Converting Machine