CIL-SP-C Automatic Colored Kitchen Towel Rewinder

The CIL-SP-C automatic colored kitchen towel rewinder can produce both colored and ordinary kitchen towel with neat edge and uniform tension. In addition to compact structure, stable performance, simple operation and high efficiency, it also features a small floor area of 8.4 square meters and high production efficiency of 120-180m/min, ideal for paper product processing.

This kitchen towel color printing and rewinding machine is suited for processing the raw paper of 1.2, 1.75, 1.95, 2.15, 2.35, 2.55 and 2.75 meters wide. It is mainly constituted by raw paper stand, conveying unit, embossing unit, gluing unit, paper feeding unit, perforating unit, winding unit, electronic control unit and cutting system. Work flow by using this automatic colored kitchen towel rewinder covers unwinding, embossing, gluing, conveying, perforating, winding and cutting.

Functions and Features

1. This equipment is designed with complete functions and PLC for production control. It boasts high automation and high production efficiency.

2. You don’t need to stop the kitchen towel rewinding machine with color printing for any operation like paper core changing, glue spraying and sealing. Besides, this device will automatically reduce and then increase working speed for core changing.

3. Our automatic colored kitchen towel rewinder enables first tight and then loose rewinding after paper core is changed to avoid the core from coming off.

4. There is automatic alarm for paper core adding, and the machine will stop if the core is used up or the paper is broken up.

5. Glue spraying and sealing can be completed at one time, and there is paper tail reserved for use convenience.

6. This colored kitchen towel rewinding machine is fit for core pipe of different specifications.

7. Pneumaticjack is used for material loading, and double sets of embossing roller are adopted for point-to-point embossment.

8. Our automatic colored kitchen towel rewinder can also be outfitted with coreless production device as well as single-color or two-color printing press for bright-colored pattern.

Main Technical Parameters

| Model | 1092C | 1575C | 2000C | 2200C | 2400C | 2600C |

| Width of raw paper (mm) | 1200 | 1750 | 2000 | 2200 | 2400 | 2600 |

| Diameter of finished product | ¢60-140mm (The tightness is adjustable.) | |||||

| Core diameter of finished paper | ¢25-50 | |||||

| Diameter of raw paper | 1200mm (Based on customer’s demand) | |||||

| Core diameter of raw paper | ¢76.2mm (Other specifications should be specified.) | |||||

| Perforation pitch | 4 cutters, 100-120mm, 2 cutters, 200-240mm (Other specifications should be specified.) | |||||

| Winding speed | 120-180m/min. | |||||

| Parameter setting | Human machine interface operating system with touch screen | |||||

| PLC | Computer programming | |||||

| Unwinding stand | 2 layers (If 3 layers are needed, please let us know.) | |||||

| Embossing device | Two-side embossment, steel-to-steel embossing | |||||

| Gluing and compounding system | Three-roller compound device producing both colored and ordinary kitchen towel | |||||

| Pneumatic system | Pressure: 5kg/cm2Pa (Prepared by customers) | |||||

| Power | 7.5-20KW | |||||

| Overall Dimension (L×W×H) | 7100×2850×1800-7100×4250×1800mm | |||||

| Weight | 3.5-7T | |||||

| Remark | Custom-made machines are available including non-standard ones. | |||||

Links:https://www.globefindpro.com/products/80829.html

-

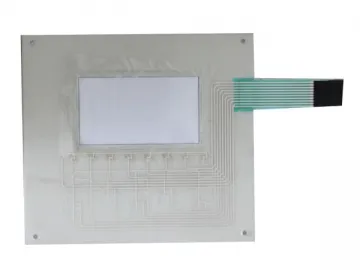

Membrane Circuit

Membrane Circuit

-

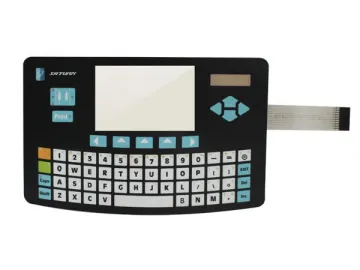

Membrane Keyboard

Membrane Keyboard

-

CIL-NP-C C Type Tissue Converting Machine

CIL-NP-C C Type Tissue Converting Machine

-

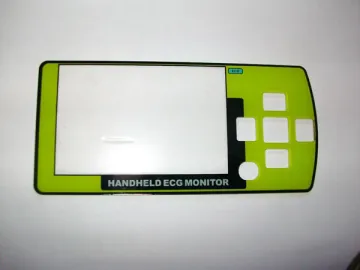

PMMA & PC Transparent Windows

PMMA & PC Transparent Windows

-

Low E Hollow Glass

Low E Hollow Glass

-

ZL15,ZL15-1 Series Gearbox

ZL15,ZL15-1 Series Gearbox

-

CIL-AS-201 Automatic Paper Handkerchief Packaging Machine

CIL-AS-201 Automatic Paper Handkerchief Packaging Machine

-

CIL-NP-7000A (275-500) Automatic Multi-Color Napkin Converting Machine

CIL-NP-7000A (275-500) Automatic Multi-Color Napkin Converting Machine

-

CIL-SP-503 Single Roll Toilet Paper Packaging Machine

CIL-SP-503 Single Roll Toilet Paper Packaging Machine

-

CIL-NP-7000K300-500-2 High Speed Napkin Converting Machine

CIL-NP-7000K300-500-2 High Speed Napkin Converting Machine

-

CIL-FT-20A Automatic Facial Tissue Converting Machine

CIL-FT-20A Automatic Facial Tissue Converting Machine

-

CIL-AS-288 Automatic Three-fold Towel Paper Converting Machine

CIL-AS-288 Automatic Three-fold Towel Paper Converting Machine