JT-504/JT-G751 Dry Lamination Adhesive

JT-504/JT-G751Dry Lamination Adhesive

Features

1. TheJT-504/JT-G751 dry lamination adhesive is a kind of multifunctionalbonding material developed for food packaging, and it works well withhigh or low speed printing machine.

2. Our product is able toprovide high initial and final bonding strength for different laminates, suchas plastic/plastic, plastic/Al foil, plastic/Al film as well as others, and thefinished laminates fit for medium-temperature steaming process which is usedfor sterilization.

3. This binding agent is odorless, and it isresistant to ageing, high temperature, acid and hot media. Aside from these, asa PU-based adhesive, it also possesses someother properties, such as good transparency, fast curing, good elasticity,excellent machinability andwettability.

4. Our dry lamination adhesive is applicable when the solid content is within25%-30%.

Technical Data

| Name | Main agent | Curing agent |

| Model | JT-504 | JT-G751 |

| Type | Two-component solvent-based polyurethane adhesive | |

| Appearance | Colorless or light yellow transparent glue | |

| Solid content (%) | 50±2 | 75±2 |

| Viscosity (mpa∙s at 25°C) | 800-2000 | 1000-3500 |

| Solvent | Ethyl acetate | |

| Proportion by weight | 100 | 15-20 |

| Storage period | 12 months | 6 months |

Glue Amount

| Application field | Dry glue amount (g/m2) |

| Multi-color printing | 2.5-3.5 |

| Al foil shielding layer of cable | 3-4 |

| Boiling or for resistance to medium | 3-4 |

| Medium-temperature steaming | Above 5 |

Working Concentration

| Main agent (kg) | Curing agent (kg) | Ethyl acetate (kg) | Concentration (%) |

| 10 | 1.5-2.0* | 12.4 | 25 |

| 10 | 1.5-2.0* | 8.5 | 30 |

Note: The symbol “*” means theamount of curing agent is adjustable within this range depending on specificapplication and ambient humidity.

Calculation Formula for Dry Glue

Cw=KhN, where

Cw is the dry glue amount(g/m2)

K is the correction factor whose typical values are within 0.25-0.17

h is the cell depth of aniloxroll (μm)

N is the solid content of adhesive (%)

Calculation Formula for Diluent

Wx=(Wz×Nz Wg×Ng)/N-(Wz Wg), where

Wx is the weight of diluent (kg)

Wz is the weight of mainagent (kg)

Nz is the solid content ofmain agent (%)

Wg is the weight of curingagent (kg)

Ng is the solid content of curing agent (%)

N is the working concentration after proportioning (%)

Links:https://www.globefindpro.com/products/80918.html

-

JT-501/JT-G751A Dry Lamination Adhesive

JT-501/JT-G751A Dry Lamination Adhesive

-

Silicone Water Cup

Silicone Water Cup

-

General Purpose Series

General Purpose Series

-

Silicone Chocolate Mould

Silicone Chocolate Mould

-

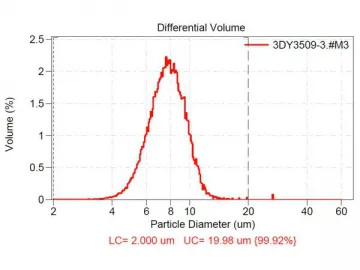

FF-5006 Laser Toner for HP CP3525/CM3530/CLJ PRO CP 5225

FF-5006 Laser Toner for HP CP3525/CM3530/CLJ PRO CP 5225

-

JT-65A/JT-G751A Dry Lamination Adhesive

JT-65A/JT-G751A Dry Lamination Adhesive

-

Silicone Glove

Silicone Glove

-

Silicone Bakeware

Silicone Bakeware

-

Silicone Baby Toothbrush

Silicone Baby Toothbrush

-

Ester Soluble Gravure Printing Ink

Ester Soluble Gravure Printing Ink

-

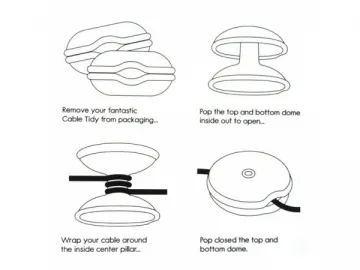

Silicone Earphone Winder

Silicone Earphone Winder

-

Thick Film Separation-Resistant Series

Thick Film Separation-Resistant Series