Alcohol Soluble Gravure Printing Ink

Brief Introduction

The alcohol soluble gravure printing ink is a kind of polyurethane-based composite ink that was developed independently by us in 2007. It is low-odor, environmental, allowing convenient use and better economic gain. Its cost-in-use is lower than that of benzene-containing or ketone-containing ink, and it can be widely used in package printing of BOPP, PET and NY.

Features

1. The solvent doesn’t contain any benzene or ketone, and ethanol could work as the main solvent. So, our product is eco-friendly and generates low odor.

2. This liquid ink is able to deliver glossy images, and excellent reproducibility of printed dot is expectable.

3. The gravure printing ink could be processed easily by the doctor blade, indicating that the excess ink will be wiped off the gravure cylinder by the doctor blade. In addition, our product fits for long-time printing jobs.

Applicable Substrates

1. Polyester (PET): The surface tension should be over 50dyn/cm2.

2. Nylon (NY): The surface tension should be over 52dyn/cm2.

3. Polypropylene (BOPP): The surface tension should be over 38dyn/cm2.

Diluent and Ink Viscosity

1. Under normal printing conditions, the medium-drying solvent could work as the diluent for full (or solid) printing and halftone printing. However, if the slow-drying solvent is applied, please pay special attention to the remaining solvent and the sticky-dirty phenomenon.

2. To get the best printing result, the viscosities of color ink and white ink are both recommended to be within 13-18 second/ZC#3.

| Solvent type | Fast-drying | Medium-drying | Slow-drying |

| Ethanol | 20 | 50 | 40 |

| Ethyl acetate | 60 | - | - |

| N-propyl acetate | - | 30 | 30 |

| Propylene glycol monomethyl ether | - | - | 10 |

| Isopropanol | 20 | 20 | 20 |

Application Range

1. The gravure printing ink finishes image transfer process easily for all kinds of printing plates, and the color intensity varies from 5% to 100%.

2. For every practical application, our ink could be adjusted accordingly to obtain the optimum result, no matter the gravure printing press is low-speed type or high-speed type.

3. The ink viscosity should be increased when larger depth (≥45μm) or lower printing speed (≤80m/min) is adopted.

Cautions

1. The alcohol soluble gravure printing ink shall not be mixed with other inks.

2. The alcohol solvent is more likely to absorb the heat of gasification during evaporation, leading to condensation of the ambient water. Thus, the drying temperature of dryer is suggested to be set within 50-70°C, and air blowing should be enhanced to promote drying process and cut down the amount of solvent residual.

3. As we know, alcohol itself contains water, and it tends to absorb water as well. So, during long-time printing job, water content of the gravure ink will get larger and larger which may deteriorate the overall printing performance. Considering this, it is highly recommended to add ink to the ink fountain in a small amount frequently instead of one time addition. Moreover, when using old inks, the proportion of ester solvent should be increased properly.

4. When preparing polyurethane adhesive, the curing agent must be enough, and its proportion needs to be enlarged (5%-20%) under humid weather to ensure thorough solidification.

Detail types of the alcohol soluble gravure printing ink

Please see the attached list: types and properties of the alcohol soluble gravure printing ink

Notes

1. The technical suggestions are based on our experience and expertise. They are true and reliable, but not guarantees because the working condition and process flow are not controllable to us.

2. Before commercial production, please check out whether our gravure printing ink fits for your equipment and the end product.

Types and Properties of the gravure printing ink

| Types | Color | Level of sun-proof | Property |

| 9000 | varnish | --- | boiling |

| 9103 | white | 8 | boiling |

| 9201 | black | 8 | boiling |

| 9301-1 | original red (blue phases) | 4 | light packaging |

| 9396 | original red (yellow phases) | 4 | light packaging |

| 9308 | bronze red | 3 | light packaging |

| 9389H | sun-proof original red | 7 | boiling |

| 9327H | sun-proof bright red | 7 | boiling |

| 9319 | nonporous peach | 8 | boiling |

| 9341 | porous peach | 3 | light packaging |

| 9401 | original yellow | 4 | boiling |

| 9405 | transparent yellow (red phases) | 6 | boiling |

| 9501 | green | 8 | boiling |

| 9601 | original blue | 8 | boiling |

| 9700 | nonporous purple | 8 | boiling |

| 9701 | porous purple | 3 | light packaging |

| 9706 | ultramarine | 4 | light packaging |

| 9901 | orange | 4 | boiling |

Notes:

1. "Level of sun-proof" has been classifies from Level 1 (lowest) to Level 8 (highest)

2. The condition of "boiling" is 100℃/30mins

Links:https://www.globefindpro.com/products/80926.html

-

Solvent-free PU Adhesive

Solvent-free PU Adhesive

-

Silicone Ice Cube Tray

Silicone Ice Cube Tray

-

Flued Water Heater

Flued Water Heater

-

700mm Built in Gas Hob

700mm Built in Gas Hob

-

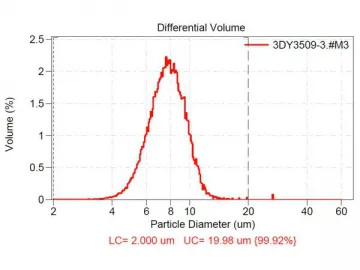

FF-5008 Laser Toner for HP CP4025/4525/CM4540/PRO400

FF-5008 Laser Toner for HP CP4025/4525/CM4540/PRO400

-

European Style Range Hood

European Style Range Hood

-

JT-503/JT-G751 Dry Lamination Adhesive

JT-503/JT-G751 Dry Lamination Adhesive

-

JT-65A/JT-G751A Dry Lamination Adhesive

JT-65A/JT-G751A Dry Lamination Adhesive

-

FF-5006 Laser Toner for HP CP3525/CM3530/CLJ PRO CP 5225

FF-5006 Laser Toner for HP CP3525/CM3530/CLJ PRO CP 5225

-

Silicone Chocolate Mould

Silicone Chocolate Mould

-

General Purpose Series

General Purpose Series

-

Silicone Water Cup

Silicone Water Cup