Solvent-free PU Adhesive

Features

The JT-1001A/JT-1001B solvent-free PU adhesive is a kind of two-component adhesive with solid content of 100%.It shows the advantages of low viscosity, no peculiar smell, outstanding adhesive strength, excellent operational flexibility, good adaptability to various kinds of high-speed solvent-free plastic/plastic bonding, etc.

Applications

Our solvent-less laminating adhesive fits perfectly for commonly used substrates including BOPP, CPP, CMCPP, CPE, PET, PE, NY, Al foil as well as other films, and it is also applicable for general water-boiling packages. Thus, it is widely used to make packages for food, medicine, daily-use chemicals, etc.

Technical Data

| Name | Curing agent | Main agent |

| Model | JT-1001A | JT-1001B |

| Appearance | Colorless or yellowish transparent viscous liquid | |

| Structure | Isocyanate component-NCO | Polyhydroxy component-OH |

| Viscosity (mPa∙s at 25℃) | 500-1000 | 500-1000 |

| Solid content (%) | 100 | |

| Proportion by weight | 100 | 70-90 |

| Storage period | 6 months | 12 months |

Glue Amount

For dry coating, the glue amount is usually controlled within 1.3-2.0g/m2.

Operation Guide

1. It is highly recommended to use this solvent-free PU adhesive at 25℃, and the glue’s viscosity is around 600mPa∙s at this temperature. Before use, please wait 30 minutes to make sure that obvious thickening phenomenon doesn’t occur during this time period. If the machine has been down for over 30 minutes, please clean the entire glue spreading system in time using common solvents such as esters and ketones.

2. The adhesive’s proportion and operating parameter should be determined on the basis of applied substrate, machine speed, working environment and other factors. For solvent-free glue, its initial bonding force is low. So, the drum heater’s temperature and pressure, as well as the rewinding pressure, need to be set at proper values to enhance the transparency and peel strength of final product.

3. The curing process is carried out at 30-50℃, and lasts for 24-48 hours. For multi-layer lamination, a 12-hour (or more) curing at room temperature or a 2-hour (or more) curing at high temperature is required by the solvent-free glue to offer a certain bonding strength, and then the second lamination operation is executed. For the room temperature curing process, if the diurnal temperature variation is pretty large, please extend the curing time to ensure complete curing.

Cautions

1. For this solvent-free PU adhesive, the applied substrate should have a clean, dry, oil-less and dust-free surface with surface tension of 38dyn/cm2 or higher. For example, the surface tension of PET needs to exceed 50dyn/cm2, and the value should be more than 52dyn/cm2 for NY.

2. This product, just like other kinds of PU adhesives, needs to be kept in a tightly sealed container, and the glue should be used up ASAP once it is prepared. It is strictly prohibited to use whitish or obviously thickened glue. In addition, the environmental relative humidity for lamination process should be lower than 85%.

3. For films with excessive slip agent (erucylamide), the adhesive strength will be deteriorated. So, the use of slip agent is strictly controlled.

4. Under the condition that PET or PA substrate is applied, you’d better place it for 24 hours after printing step to achieve optimum result.

Product Package and Storage

As mentioned above, this solvent-free PU adhesive comprises of two component which are curing agent (JT-1001A) and main agent (JT-1001B). For JT-1001A, it is packed 20kg/barrel, and for JT-1001B, it is packed 16kg/barrel if there is no special requirement.

Our product should be stored in a closed container at room temperature.

Notes

1. The technical suggestions are based on our experience and expertise. They are true and reliable, but not guarantees because the working condition and process flow are not controllable to us.

2. Before commercial production, please check out whether our solvent-free PU adhesive fits for your equipment and the end product.

3. Due to technological upgrade, the technical data you got may not be the latest version, and the update will be made without prior notice.

Links:https://www.globefindpro.com/products/80927.html

-

Silicone Ice Cube Tray

Silicone Ice Cube Tray

-

Flued Water Heater

Flued Water Heater

-

700mm Built in Gas Hob

700mm Built in Gas Hob

-

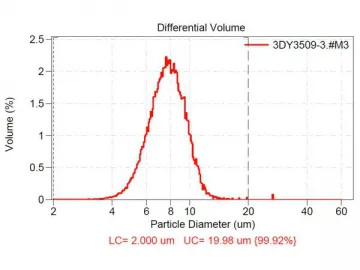

FF-5008 Laser Toner for HP CP4025/4525/CM4540/PRO400

FF-5008 Laser Toner for HP CP4025/4525/CM4540/PRO400

-

European Style Range Hood

European Style Range Hood

-

FF-1007 Laser Toner for Konica Minolta 1600W/1650EN/1680MF/1690MF

FF-1007 Laser Toner for Konica Minolta 1600W/1650EN/1680MF/1690MF

-

Alcohol Soluble Gravure Printing Ink

Alcohol Soluble Gravure Printing Ink

-

JT-503/JT-G751 Dry Lamination Adhesive

JT-503/JT-G751 Dry Lamination Adhesive

-

JT-65A/JT-G751A Dry Lamination Adhesive

JT-65A/JT-G751A Dry Lamination Adhesive

-

FF-5006 Laser Toner for HP CP3525/CM3530/CLJ PRO CP 5225

FF-5006 Laser Toner for HP CP3525/CM3530/CLJ PRO CP 5225

-

Silicone Chocolate Mould

Silicone Chocolate Mould

-

General Purpose Series

General Purpose Series