Q1322 Pipe Threading Lathe Machine

Features

1. The adoption of the tapered roller bearing can ensure that the spindle of the Q1322 pipe threading lathe machine has sufficient rigidity.

2. The spindle bore has large diameter. The front and rear double chucks are fitted to the spindle. We can also configure the spindle with the electric chuck according to the requirements of the customers.

3. The brake and rotation direction changing of the spindle are implemented via the hydraulic control. The brake is very reliable and sensitive.

4. The headstock of the pipe threading lathe machine works with hydraulic oil forced lubricating.

5. The machine bed slide way going through the supersonic frequency hardening is durable and wear resistant. The saddle slide way is inlaid with the wear-resisting material to effectively eliminate the stick-slip motion.

6. The machine bed of the machine is widened to 600mm, making a great improvement of the rigidity of the machine. Heavy cutting to the high strength materials can be conducted easily.

7. We can also manufacture the pipe threading lathe machine by heightening the headstock or lengthening the lathe bed to broaden the machining range of the machine.

Application Range

The product is the special machine tool applied in the fields concerning oil drilling, geology and metallurgy for processing various kinds of pipes and pipe threads. Apart from the basic functions of lathing the pipe threads, metric and inch threads of circular cylinder and taper tube, it can also complete outer circle lathing, hole boring, and inside and outside taper holes processing. The machine is very capable of processing and repairing the pipes and fittings.

Manufacturing Equipment

The pipe threading lathe machine is fabricated by adopting the slideway grinding machine, gantry planing machine, gantry milling machine, supersonic frequency induction hardening machine, CNC boring machine tool, etc.

| Overall Dimension and Weight | ||

| Length | 3300mm | |

| Width | 1450mm | |

| Height | 1500mm | |

| Weight | 5600kg | |

| Main Specification | ||

| Max. Machining Taper | 1: 4 | |

| Max. Work Piece Rotation Diameter | 630mm | |

| Machining Pipe Diameter | 50-219mm | |

| Max. Machining Length of Ordinary Shaft | 1000mm | |

| Max. Stroke of Taper Bar | 750mm | |

| Spindle | ||

| Number of Spindle Speeds | 12 | |

| Spindle Bore Diameter | 225mm | |

| Spindle Speed Range | 20-460r/min | |

| Feed System | ||

| Number of Longitudinal and Cross Feed Rates | 32 for Each | |

| Toolpost Feeding Range per Revolution of Spindle | Longitudinal: 0.1-1.46mmTransverse: 0.04-0.65mm | |

| Number of Machinable Metric Thread | 21 | |

| Number of Machinable Inch Thread | 26 | |

| Machinable Metric Thread Pitch | 1-15mm | |

| Machinable Inch Thread Pitch | 1-14t.p.i | |

| Saddle Longitudinal Rapid Traverse Speed | 2.5m/min | |

| Longitudinal Travel of Saddle When Apron Handwheel Rotating One Grid | 0 .20mm | |

| Toolpost | ||

| Max. Stroke of Compound Rest | 200mm | |

| Tool Sectional Dimension | 30 × 30mm | |

| Toolpost Rotary Table Rotation Angle | ± 90° | |

| Toolpost Travel When Compound Rest Dial Turning A Grid | 0.05mm | |

| Toolpost Travel When Bottom Slide Dial Turning A Grid | 0.05mm | |

| Vertical Distance from Spindle Center Line to Toolpost Installation Benchmark | 30mm | |

| Tailstock | ||

| Center Barrel Diameter | 100mm | |

| Center Barrel Stroke | 250mm | |

| Tailstock Transverse Movement Range | ±15mm | |

| Center Barrel Taper | Morse No. 5 | |

| Center Taper | Morse No. 5 | |

| Power | ||

| Gear Pump Belt | 1- ○ 800 | |

| Fast Electric Motor | 2AOS5632 /0.37kW 2700r/min | |

| Main Motor Belt | 4-B2240 | |

| Cooling Electric Pump | JCB-22 0.125kW 22L/min | |

| Gear Pump | CB-B6 2.5Mpa 1450r/min | |

| Main Electric Motor | Y160M-4-B3 11kW 1460r/min | |

Related Names

Heavy Duty Cutting Machine | Cylindrical Turning Machine | Internal Threading Tool

Links:https://www.globefindpro.com/products/81308.html

-

35W-150W Waterproof LED Driver

35W-150W Waterproof LED Driver

-

XY-44A Core Drilling Rig

XY-44A Core Drilling Rig

-

HZ-200GT Water Well Drilling Rig

HZ-200GT Water Well Drilling Rig

-

BW-200 Mud Pump

BW-200 Mud Pump

-

Manual/Semi-Automatic Pipe Cutting Circular Saw

Manual/Semi-Automatic Pipe Cutting Circular Saw

-

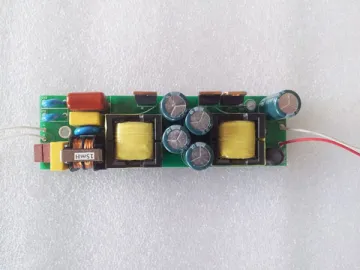

190W-220W Waterproof LED Driver

190W-220W Waterproof LED Driver

-

XY-44B Intelligent Electric-Control Drilling Rig

XY-44B Intelligent Electric-Control Drilling Rig

-

XYX-2 Trailer-Mounted Water Well Drilling Rig

XYX-2 Trailer-Mounted Water Well Drilling Rig

-

5W-12W Built-in LED Driver

5W-12W Built-in LED Driver

-

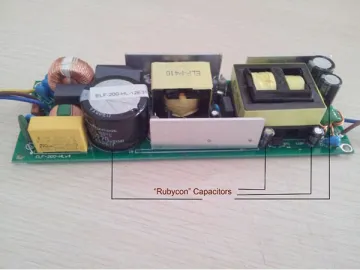

25W-100W Built-in LED Driver

25W-100W Built-in LED Driver

-

XYC-8B Truck-Mounted Intelligent Electric-Control Core Drilling Rig

XYC-8B Truck-Mounted Intelligent Electric-Control Core Drilling Rig

-

100W 24V LED Driver

100W 24V LED Driver