Double Cylinder Hydraulic Ironworker

Descriptions

The double cylinder hydraulic ironworker enables shearing, punching and die cutting of plates and square, round, U, angle and I steel as well as various structural steel materials. It is the first choice for mass processing of structural steel materials, and capable of bending the plates with the length of less than 500mm. The punching part is designed with a protective cover and the automatic stop gauge is mounted onto the machine back. We promise that all the components are provided in line with the highest quality requirements in safety, function, maintenance and performance aspects.

Features

1. The hydraulically driven double cylinder hydraulic ironworker is the up-to-date product in the domestic industry of punching and shearing machine.

2. The double hydraulic stations work independently. Due to 5 stations, multiple processing modes are obtainable.

3. The whole machine is configured with standard punching station, shearing station of U and angle steel, shearing station of thick plates, cutting-off station of round and square steel as well as chamfering station.

4. Components for large hole punching, plate bending, U and structural steel punching as well as chamfering of shutters and tubes are optionally available.

5. Manufactured by the advanced European technology, this machine is integrally structured by means of welding and treated with high-temperature quenching. Hence, it has high rigidity and strength. Additionally, since processed with special high temperature vacuum treatment, the tool life is largely extended.

Technical Parameters (Unit: mm)

| Item | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-35 | Q35Y-40 |

| Punching | ||||||

| Maximum punching capacity | 25x16 | 30x20 | 35x25 | 38x30 | 40x32 | 40x40 |

| Maximum stroke | 80 | 80 | 80 | 80 | 100 | 110 |

| Throat depth | 300 | 355 | 400 | 600 | 650 | 700 |

| Maximum punching diameter(Optional) | 160 | 160 | 160 | 160 | 160 | 160 |

| Working height | 1030 | 1084 | 1142 | 1209 | 1100 | 1190 |

| Shearing | ||||||

| Maximum plate thickness of shearing | 250x16 | 330x20 | 330x25 | 355x30 | 380x35 | 400x40 |

| Maximum plate width of shearing | 400x8 | 480x10 | 600x16 | 600x20 | 600x25 | 700x30 |

| Side cutting of angle flange | 100x10 | 100x13 | 100x14 | 100x16 | 100x18 | 100x20 |

| Working height | 890 | 894 | 851 | 897 | 897 | 897 |

| Angle cutting | ||||||

| 90° angle steel shearing | 125x12 | 140x14 | 160x14 | 180x16 | 200x14 | 200x16 |

| 45° angle steel shearing | 70x10 | 70x10 | 70x10 | 70x10 | 100x10 | 100x10 |

| Working height | 1130 | 1139 | 1200 | 1220 | 1220 | 1220 |

| Section cutting | ||||||

| Round/square steel | 45/40 | 50 | 60/50 | 65/55 | 70/60 | 70/60 |

| U/I steel | 126x53 | 160x65 | 200x75 | 280x86 | 300x90 | 300x90 |

| T steel | 90x12 | 90x12 | 90x12 | 90x12 | 90x12 | 90x12 |

| Notching | ||||||

| Thickness | 10 | 12 | 14 | 16 | 16 | 16 |

| Width | 57 | 57 | 57 | 57 | 57 | 57 |

| Depth | 60-90 | 60-90 | 60-90 | 60-90 | 60-90 | 60-90 |

| Notching of angle steel | 100x10 | 100x13 | 100x14 | 100x16 | 110x18 | 110x20 |

| Working height | 890 | 883 | 886 | 898 | 898 | 898 |

Related Names

Metal Punch and Shear Machine | Steel Plate Bending Machine | Hydraulic Metal Cutter

Links:https://www.globefindpro.com/products/81319.html

-

Dimmable LED Driver with Sound Sensor

Dimmable LED Driver with Sound Sensor

-

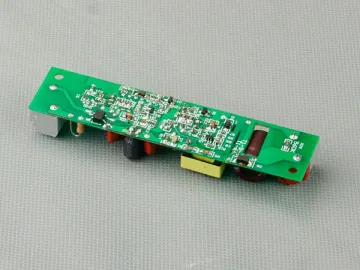

PWM/Resistive Load Dimmable LED Driver

PWM/Resistive Load Dimmable LED Driver

-

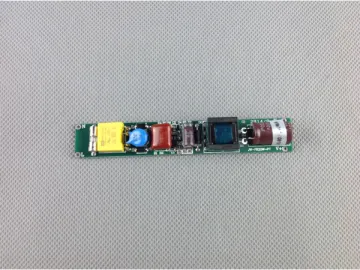

30W-45W LED Driver

30W-45W LED Driver

-

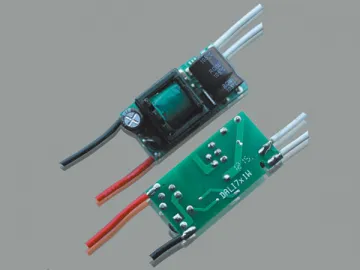

5-7W Constant Current LED Driver

5-7W Constant Current LED Driver

-

70W-110W Waterproof LED Driver

70W-110W Waterproof LED Driver

-

25W-40W Waterproof LED Driver

25W-40W Waterproof LED Driver

-

Horizontal Lathe

Horizontal Lathe

-

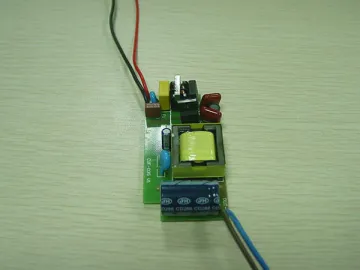

15W-30W LED Driver

15W-30W LED Driver

-

Q43-3150 Hydraulic Alligator Shear

Q43-3150 Hydraulic Alligator Shear

-

Non-Isolated LED Driver

Non-Isolated LED Driver

-

190W-220W Waterproof LED Driver

190W-220W Waterproof LED Driver

-

Manual/Semi-Automatic Pipe Cutting Circular Saw

Manual/Semi-Automatic Pipe Cutting Circular Saw