EB Series Single Head 3D Pipe Bender

Features

1. The EB series single head 3D pipe bender comes with NC control and auxiliary drive. Automatic aerial angle turning makes the operation more convenient and efficient. It is widely applied to process various kinds of tubes.

2. With PLC control and hydraulic drive, it enables the prefabrication of tubes with various bending angles.

3. It is designed with a human-machine touch screen and shows in English for operation and visual convenience. You can choose manual, semi-automatic and automatic operating modes.

4. Starting up and emergency stop can be realized via the mobile foot switch.

5. Due to the advanced imported feed guide rail and locator, the feed length is precisely positioned.

6. The EB series single head 3D pipe bender adopts the servo motor of Japanese Mitsubishi and enables automatic aerial angle turning, thus it can bend 3D tubes with multiple angle heads.

7. The hydraulic, control, driving and display systems are imported from international brands with high reliability, accuracy and efficiency. Hence, this machine is capable of mass production and has achieved both international and domestic advanced levels.

8. The whole machine is provided with merits like easy operation, stable performance, high efficiency, high safety factor, etc. It is an ideal choice for tube processing.

Technical Parameters

| Item | Unit | EB25 | EB38 | EB50 | EB63 | EB75 | |

| Maximum bending tube diameter × wall thickness | mm | Φ25×1.6 | Φ38×2 | Φ50×3 | Φ63×4 | Φ75×4 | |

| Maximum bending radius (1) | mm | R100 | R180 | R250 | R250 | R250 | |

| Minimum bending radius (2) | mm | Upon tube diameter | Upon tube diameter | Upon tube diameter | Upon tube diameter | Upon tube diameter | |

| Maximum bending angle | Degree | 190 | |||||

| Maximum feed length (3) | mm | 2500 | 2500 | 3000 | 3000 | 3000 | |

| Accuracy | Tube bending accuracy | ±1゚ | ±1゚ | ±1゚ | ±1゚ | ±1゚ | ±1゚ |

| Tube turning accuracy | ±1゚ | ±1゚ | ±1゚ | ±1゚ | ±1゚ | ±1 ゚ | |

| Feed accuracy | Mechanical constant value | Mechanical constant value | Mechanical constant value | Mechanical constant value | Mechanical constant value | Mechanical constant value | |

| Servo motor power for tube turning | KW | 0.4 | 0.75 | 0.75 | 0.75 | 1 | |

| Allowable bent tube number | Piece | 16 | |||||

| Storable component number (4) | Set | 16 | |||||

| Hydraulic motor power | KW | 3 | 4 | 5.5 | 5.5 | 7.5 | |

| Maximum system pressure | MPa | 12 | 12 | 12 | 12 | 12 | |

| Overall dimension | mm | 3000×760×1100 | 3800×720×1100 | 4900×1300×1300 | 4900×1300×1300 | 5110×1300×1300 | |

| Weight | kg | 1000 | 1500 | 2500 | 3000 | 4500 | |

| Note: (1) and (3) are upon the specific requirements of customers. (2) depends on the tube diameter and (4) can be increased. | |||||||

| Item | Unit | EB89 | EB100 | EB115 | EB130 | EB168 | |

| Maximum bending tube diameter × wall thickness | mm | Φ89×8 | Φ100×8 | Φ115×10 | Φ130×8 | Φ168×14 | |

| Maximum bending radius (1) | mm | R250 | R350 | R350 | R400 | R500 | |

| Minimum bending radius (2) | mm | Upon tube diameter | Upon tube diameter | Upon tube diameter | Upon tube diameter | Upon tube diameter | |

| Maximum bending angle | degree | 190 | |||||

| Maximum feed length (3) | mm | 3000 | 3000 | 3000 | 3500 | 3600 | |

| Accuracy | Tube bending accuracy | ±1゚ | ±1゚ | ±1゚ | ±1゚ | ±1゚ | ±1゚ |

| Tube turning accuracy | ±1゚ | ±1゚ | ±1゚ | ±1゚ | ±1゚ | ±1゚ | |

| Feed accuracy | Mechanical constant value | Mechanical constant value | Mechanical constant value | Mechanical constant value | Mechanical constant value | Mechanical constant value | |

| Servo motor power for tube turning | KW | 1.5 | 1.5 | 2 | 2 | 3.5 | |

| Allowable bent tube number | Piece | 16 | |||||

| Storable component number (4) | Set | 16 | |||||

| Hydraulic motor power | KW | 11 | 15 | 22 | 22 | 22 | |

| Maximum system pressure | MPa | 12 | 14 | 14 | 14 | 16 | |

| Overall dimension | mm | 5650×1350×1360 | 5700×1350×1400 | 6120×1460×1400 | 6630×1920×1600 | 8100×1955×1660 | |

| Weight | kg | 5500 | 6000 | 7000 | 8000 | 12000 | |

| Note: (1) and (3) are upon the specific requirements of customers. (2) depends on the tube diameter and (4) can be increased. | |||||||

Related Names

Steel Boiler Tube Bender | Curved Pipe Machine | Hydraulic Pipe Bending Machine

Links:https://www.globefindpro.com/products/81361.html

-

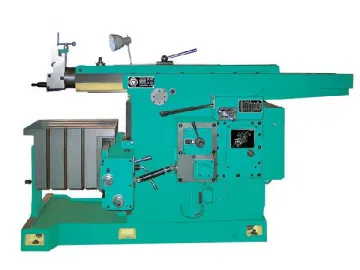

Shaping Machine

Shaping Machine

-

ED Series Double Head Pipe Bender

ED Series Double Head Pipe Bender

-

CNC Water Jet Cutter

CNC Water Jet Cutter

-

Hydraulic Semi-Automatic Pipe Cutting Circular Saw

Hydraulic Semi-Automatic Pipe Cutting Circular Saw

-

CNC Pipe Bender

CNC Pipe Bender

-

GWC29-193-965 Glazed Roof Tile Roll Forming Machine

GWC29-193-965 Glazed Roof Tile Roll Forming Machine

-

Manual Surface Grinder

Manual Surface Grinder

-

EMH25 Series C-frame Two Point Pneumatic Press

EMH25 Series C-frame Two Point Pneumatic Press

-

NC Profile Shaping Machine

NC Profile Shaping Machine

-

Foot Pedal Operated Riveting Machine

Foot Pedal Operated Riveting Machine

-

Four-Roller Plate Rolling Machine

Four-Roller Plate Rolling Machine

-

Knee Type Milling Machine

Knee Type Milling Machine