CNC Water Jet Cutter

| Gantry type CNC water jet cutting machine | Cantilever type CNC water jet cutting machine | Detailed drawing |

General Description

The CNC water jet cutter is mainly constituted by the CNC cutting platform, high pressure system, CAD or CAM software system, cutting head, high-pressure water switching valve, sand control system and the other components. You can also configure it with other optional systems like the automatic grinding material supply system, water softening system, oil cooling system, etc.

Regarding to the export packing mode, we usually apply the honey comb pallet box to pack the high pressure system and the control system. As for the other systems and components, nude packing is our practice.

Details

1. Classification

Generally, the CNC water jet cutter is classified into four types, i.e. the gantry type (380MPa) (EMA), gantry type (420MPa) (EMB), cantilever type (380MPa) (ECA) and the cantilever type (420MPa) (ECB).

2. Working Table

The working table is available in the dimension of 1×1mm, 1.5×1.5mm, 2×1.5mm and 3×1.5mm to satisfy the different requirements of customers.

3. Technical Features

Complying with CE standard, this equipment comes with highly stiff dual motor drive and heavy-duty support, and features stable transmission. The dedicated CNC system provided precise control. Besides, double cutting heads can be configured.

4. Split-body Design

The brand-new split-body design highlights the noble temperament and highly durable performance of the CNC water jet cutter. The heavy-duty steel structure is sturdy and stable, making for a more robust and reliable machine. The dedicated CNC system and the AC servo drive contribute to high-quality processing. All the key elements are introduced from internationally well-known brands.

5. Other Configurations

The centralized automatic lubrication system is adopted for convenient maintenance. The drag chain from renowned brand features flexibility in movement. The special-purpose flexible cable is extremely durable and reliable. In addition, the high-end sensor provides dependable soft and hard limit, so the processing is very safe.

6. New-type Schemes

The X and Y axis adopts the totally enclosed dustproof design, and the Y axis is equipped with nut structural transmission, thus possessing higher stiffness. Additionally, as the Y axis is designed with double guide ways, double drives as well as the high-quality ball screw from international brand, the CNC water jet cutter is characterized by high precision, stable transmission and high durability.

Cutting System

1. CNC Cutting Platform

a. The steel structural beam and body conduce to excellent precision and stability of this equipment.

b. The body and the water tank adopt the split design for relieving the compression towards the moving elements caused by water sands and the original processing components.

c. The ball screw transmission is adopted.

2. Control System

a. We adopt the well-known Chinese control system as well as AC digital servo drive and AC servo motor of Mitsubishi.

b. A 17″ LCD screen is equipped.

c. DNC on-line processing function is available for the CNC water jet cutter.

d. Return from any position along the original track is achievable. Also, automatic deceleration for corner and small circular arc processing is attainable.e. Graphical analog display of cutting track can be obtained.

f. A 80GB storage hard disc and a 1GB flash memory card are provided for users.

g. The multi-language support function is provided so that languages can be shifted by changing the system parameters.

h. The drive-by-wire handheld controller is optionally available.

3. Drive System

The gapless ball screw and the linear guide way are introduced from HIWIN or ABBA of Taiwan, which can ensure high transmission accuracy, high durability and quality.

4. Protection System

a. The CNC water jet cutter is designed with automatic overtravel limit and soft limit protection functions.

b. The unique protective design consisting of new-type labyrinth protection and Z axis wholly enclosed water jet safely prevent the ball screw and the guide rail from the corrosion of sand and water backwash during cutting.

5. Lubrication System

The automatic centralized lubrication system ensures that the lubricating oil timely reaches each lubricating point of drive system, thus this machine can work stably and reliably with simple maintenance.

Abrasive Cutting System

This system of CNC water jet cutter is mainly comprised of the all-in-one abrasive cutting head, high pressure water switch, grinding material gauge, control valve and the sand hopper.

1. All-in-one Abrasive Cutting Head

This independently developed cutting head is a high-efficient one in the current water jet cutting industry. It comes with automatic adjustment function to save the assembly time. All the quick-wear parts can be easily replaced.

2. High Pressure Water Switch

a. This switch utilizes a pneumatic valve that can realize instant opening and instant or delayed shutting of high-pressure water flow. The CNC auxiliary function helps to achieve automatic control of high-pressure water.

b, The blockage pressure can be freely adjusted to achieve low-pressure perforation.

3. Sand Feed System

The CNC water jet cutter adopts the self-suction continuous sand feed mode. Manual sand supplying is achievable. Automatic sand feed will be available if the automatic sand feed system is configured.

4. Sand Control Valve

a. The electric sand supply mode is used to overcome the defects of traditional self-suction sand feed mode.

b. Instead of the electromagnetic valve, a pneumatic valve is adopted. Thus, sand blockage or stoppage caused by failed magnetism can be avoided.

c. Manual operation of sand flow via the speed regulating motor is attainable, allowing for easy operation.

d. With the CNC auxiliary function, the supply of grinding materials is automatically controlled.

5. Sand Hopper

The side hanging sand hopper utilized by the CNC water jet cutter comes with a side window for observing grinding material using conditions for informing the operator to timely supplement the sand. A fully loaded sang hopper can afford sand consumption of continuous 15 to 30 minutes.

High Pressure System (Optionally KMT or Accustream)

1. Technical Features

Conforming to the CE standard, the high pressure system stably and continuously works for 24 hours with stable pressure without fluctuation. The perfect automatic diagnosis and protection function is available. What’s more, the key components are introduced from American or German brands.

2. Safety Protection System

The hydraulic system enables double filtration to ensure the operation safety and the water inflow adopts 3-level fine filtration from 5μm, 1μm to 0.45μm. Thanks to the oil temperature detection and protection device, the CNC water jet cutter will automatically stop once the temperature is over 60°C. In addition to the oil temperature alarm, multiple alarm devices are configured, including the underpressure, overpressure, blockage and over hydraulic alarm devices.

3. Main Configurations

The low pressure oil pipeline adopts the imported reliable C type conical connector which is high pressure resistant and easily maintained. The ceramic piston as well as the imported original high pressure and low pressure oil seals are equipped to ensure the stability and life span of the whole system. The high pressure oil pipeline is equipped with a stiff conical seal and the sealing effect is remarkable.

4. Automatic Air Cooling System (Optional)

This system performs forced cooling towards the hydraulic oil and improves the running conditions of the hydraulic system, thus the continuous working time and the service life of the CNC water jet cutter is extended.

5. Cooling System of Circulating Water (Optional)

This system better guarantees the continuous working condition of hydraulic system, saves the precious water resource, and also ensures that the oil temperature is below 55°C.

6. Automatic Grinding Material Conveying System (Optional)

This system has the functions of storing sands and automatically conveying the grinding materials to the CNC working platform, which improves the production efficiency, relieves the labor intensity and enhances the automaticity.

This system is simple, reliable and free from maintenance. The high-sensitivity sensor and the signal light inform the operator of adding the sands into the container at the right time. 170L sand is enough for 500 to 800 minutes cutting processing. Besides, this system enables to simultaneously and automatically supply the sands for two sets of CNC water jet cutters.

7. Water Softening System (Optional)

This system is used to remove the calcium and magnesium ions and extend the life of high-pressure sealing, jet nozzle and other components. The water yield is 2T per hour and this system enables to serve multiple sets of machines at the same time.

8. Double Cutting Heads (Changeable according to Requirements)

Double cutting heads can be applied to the cutting machine that comes with larger CNC cutting platform and the high-power high-pressure system. Working with either one cutting head or two cutting heads is achievable via the rotary knob on the control panel. By using two cutting heads, the cutting efficiency will be doubled.

9. Automatic Dredging System

This system can automatically remove the sand inside the water tank, providing convenience for the segregation of sand and water. Meanwhile, it lessens the labor intensity and improves the automaticity and productivity of the CNC water jet cutter.

Applications

This cutting machine is applicable for the following materials:

| Stainless steel | Leather | Glass |

| Aluminum | Acrylic materials | Aluminum |

| PVC | Metal | Marble |

Related Names

Precision Waterjet Cutting Machine | High Pressure Waterjet Cutter | Abrasive Water Jet Cutting Equipment

Links:https://www.globefindpro.com/products/81364.html

-

Hydraulic Semi-Automatic Pipe Cutting Circular Saw

Hydraulic Semi-Automatic Pipe Cutting Circular Saw

-

CNC Pipe Bender

CNC Pipe Bender

-

GWC29-193-965 Glazed Roof Tile Roll Forming Machine

GWC29-193-965 Glazed Roof Tile Roll Forming Machine

-

EMS21 Series C-Frame Deep-Throat Fixed Bolster Mechanical Presses

EMS21 Series C-Frame Deep-Throat Fixed Bolster Mechanical Presses

-

Automatic Pipe Punching Line

Automatic Pipe Punching Line

-

Hydraulic Punching Machine

Hydraulic Punching Machine

-

ED Series Double Head Pipe Bender

ED Series Double Head Pipe Bender

-

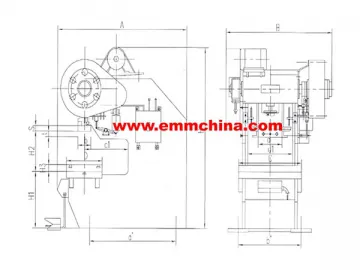

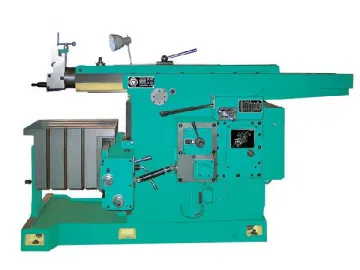

Shaping Machine

Shaping Machine

-

EB Series Single Head 3D Pipe Bender

EB Series Single Head 3D Pipe Bender

-

Manual Surface Grinder

Manual Surface Grinder

-

EMH25 Series C-frame Two Point Pneumatic Press

EMH25 Series C-frame Two Point Pneumatic Press

-

NC Profile Shaping Machine

NC Profile Shaping Machine