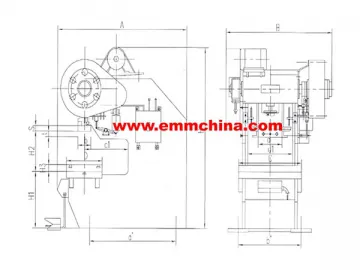

Hydraulic Slotting Machine

Features

1. The hydraulic slotting machine is built for processing various worpieces with flat, cambered surfaces or key grooves, or dies with 0 to 10 degrees tilt angle. It suits the single-piece or small-scale production.

2. The working table is designed with three different feed modes, including longitudinal, lateral and rotary modes. Therefore, multiple sides of one-time clamped workpieces realize continuous processing.

3. This equipment is designed with the hydraulic gear driving the reciprocating motion of ram, and also with the hydraulic feed unit.

4. The ram moves in a constant speed for each stroke, and the motion of both the ram and the working table can be adjusted in stepless mode.

5. The hydraulic slotting machine is designed with a reversing mechanism providing reversible oil supply for the ram.

6. The hydraulic feed works instantaneously when return stroke begins, superior to the drum wheel feed adopted by the mechanical slotter.

Advantages

Compared with the traditional mechanical slotter, this equipment has the following remarkable advantages:

1. It saves the energy. Although the power of utilized SY100E motor is only 11KW, the cutting capacity reaches up to 27KN (2.7T). Hence, the electric power consumption is greatly reduced.

2. The hydraulic transmission is equipped with the safety valve for overload protection. Therefore, the safe production is well guaranteed. Meanwhile, this product features high stability under low-speed running state, and the running speed is adjusted in stepless mode, which is incomparable for the mechanical slotter.

3. The hydraulic slotting machine realizes automatic lubrication, thereby the service life is largely extended and the production cost is decreased.

4. The automatic cutter lifting is very reliable and safe, avoiding cutter abrasion and prolonging the cutter life span.

5. The hydraulic automatic hold-down mechanism works via the cylinder to prevent cutter back-off caused by overweight cutter bar. Consequently, the processed workpieces are featured by high brightness, smoothness and accuracy.

6. As the oil pump directly supplies the feed mechanism with oil, the feed accuracy is enormously enhanced. The feed speed is also adjusted steplessly, so the operation is convenient and the feed is stable.

Technical Parameters

| Item | SY80E | SY100E | SY125E | Unit |

| Maximum ram stroke | 800 | 1000 | 1280 | mm |

| Minimum ram stroke | 125 | 125 | 300 | mm |

| Maximum slotting length | 800 | 1000 | 1250 | mm |

| Vertical adjustment distance of ram | 732 | 1090 | 1020 | mm |

| Maximum speed of ram stroke | 22 | 22 | 30 | m/min. |

| Minimum speed of ram stroke | 5 | 5 | 7 | m/min. |

| Speed ratio of working stroke and return stroke of ram | 1:1.45 | 1:1.45 | 1:1.45 | |

| Speed adjustment of working stroke | Stepless | Stepless | Stepless | |

| Maximum cutting force | 27 | 27 | KN | |

| Distance from cutter head bearing surface to the front wall of machine body | 1246 | 1151 | 1600 | mm |

| Distance from working table surface to carriage end | 1000 | 1250 | 1620 | mm |

| Maximum longitudinal movement distance of working table | 1200 | 1400 | 1500 | mm |

| Maximum lateral movement distance of working table | 1070 | 1100 | 1250 | mm |

| Working table diameter | Φ1000 | Φ1400 | Φ1400 | mm |

| Ram tilt angle | 0-10 | 0-10 | 0-10 | ゚ |

| Longitudinal feed range (stepless) | 0-1.5 | 0-1.5 | 0-1.5 | mm |

| Lateral feed range (stepless) | 0-3 | 0-3 | 0-3 | mm |

| Rotary feed range (stepless) | 0゚-1゚15' | 0゚-1゚15' | 0゚-1゚15' | ゚ |

| Maximum loading capacity of working table | 4000 | 4000 | 6000 | kg |

| T-type groove width of working table | 22H8 | 28H8 | 28H8 | |

| Main motor power, speed | 11KW, 960r/min. | 11KW, 960r/min. | 11KW, 960r/min. | |

| Quick motor power, speed | 1.5KW, 940r/min. | 1.5KW, 940r/min. | 1.5KW, 940r/min. | |

| Cooling pump motor model | DB-12B, 40W 380W | DB-12B, 40W 380W | DB-12B, 40W 380W | |

| Net weight (approximate) | 14000 | 15500 | 17800 | kg |

| Overall dimension (length × width × height) | 4125×2742×4229 | 4125×2755×4888 | 4300×3050×5400 | mm |

Related Names

Heavy Duty Slotter Machine | Keyway Broaching Tool | Workshop Machinery

Links:https://www.globefindpro.com/products/81372.html

-

Mechanical Ironworker

Mechanical Ironworker

-

Hydraulic Automatic Feed Pipe Cutting Circular Saw

Hydraulic Automatic Feed Pipe Cutting Circular Saw

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Horizontal/Vertical Turret Milling Machine

Horizontal/Vertical Turret Milling Machine

-

GWC65-185-555 Floor Deck Roll Forming Machine

GWC65-185-555 Floor Deck Roll Forming Machine

-

Guide Rail Roll Forming Machine

Guide Rail Roll Forming Machine

-

Mechanical Slotting Machine

Mechanical Slotting Machine

-

Hydraulic Punching Machine

Hydraulic Punching Machine

-

Automatic Pipe Punching Line

Automatic Pipe Punching Line

-

EMS21 Series C-Frame Deep-Throat Fixed Bolster Mechanical Presses

EMS21 Series C-Frame Deep-Throat Fixed Bolster Mechanical Presses

-

GWC29-193-965 Glazed Roof Tile Roll Forming Machine

GWC29-193-965 Glazed Roof Tile Roll Forming Machine

-

CNC Pipe Bender

CNC Pipe Bender