Horizontal/Vertical Turret Milling Machine

Descriptions

The horizontal and vertical turret milling machine, also known as radial miller, is mainly constructed by the high-quality cast iron, which has a long service life and high precision because of artificial aging treatment. The lifting table configured with a rectangular slideway has multiple contact surfaces and high stiffness. After high frequency treatment, fine grinding and plastic coating, the slideway is featured by splendid running precision and reliability.

The spindle is made from the chromium molybdenum alloy and equipped with the precision angular contact bearing, possessing strong cutting force and high accuracy after thermal refining and fine grinding.

Usages

The horizontal and vertical turret milling machine, a light-duty universal machine tool with vertical and horizontal milling functions, is applicable for small and medium sized workpieces with flat or angular surface, or with groove, spline and other surface shapes. It has been extensively used by machining, die, instrument and other industries.

UT432B

This product comes with a vertical cutter head of Taiwan brand as well as a 5HP or 2HP motor. The operating platform enables 45-degree rotation and the processing range is extremely wide. Three-axis automatic feeding features large torque and strong power. Rapid movement of 2000mm/min. is achievable.

UT436

The UT436 horizontal and vertical turret milling machine with high-speed cutter head of Taiwan brand features high precision, high rotation speed, large table stroke, high stability and two-axis feeding. The electric lifting of Z axis is available. Besides, the three axis is treated with hardening.

UT432C/UT432B

With a high-speed cutter head, the two products are characterized by large power, high rotation speed, two axis automatic feeding and Z axis automatic lifting.

UT432D

This product is configured with a stand-alone vertical milling system on the basis of 3S and 4S series. It enables two axis feeding and suits component processing and die manufacturing industries. The Z axis is optionally available with a lifting system and a plug.

Technical Parameters

| Item | 3S/4S | 5S |

| Working table size | Standard: 254mm×1270mmOptional: 254mm×1370mm | 305×1370mm (12″×54″) |

| Working table stroke | 850mm×425mm×400mm | 800×480×460mm |

| T-type groove quantity and size | 3/16/63.35mm | 3/16/63.35mm |

| Slider stroke | 469mm | / |

| Distance from spindle to table surface | 0-445mm | / |

| Distance from spindle center to column surface | 140-609mm | / |

| Spindle taper | Standard: R8/ISO30Optional: ISO40 | NT30#R8/NT40 |

| Sleeve diameter | ¢85.7mm/¢3.37in. | ¢105mm/¢4.13in. |

| Spindle travel | 127mm / 5in | 127mm/5in |

| Spindle speed | 50Hz 65-4660 (16 steps) 60Hz 80-5440RPM (16 steps) | 50Hz 65-4660 (16 steps) |

| Variable: 60-4200 | 60Hz 80-5440 (16 steps) | |

| Spindle automatic feeding | Three steps: 0.04 (0.0015″)/0.08 (0.003″)/0.15 (0.006″)mm/revolution | / |

| Rotary scope of cutter head (left to right/front to back) | 90°/45° | 90°/45° |

| Spindle motor | 2.25KW/3HP | 3HP/5HP |

| Net weight | 1380kg | 1650kg |

| Item | UT436B | UT436 | UT432A | UT432C | UT432B |

| Spindle taper | ISO40 (V) ISO50 (H) | 7:24 ISO40 (V)/7:24 ISO50 (H) | ISO40 | ISO40 | ISO40 |

| Spindle travel | / | / | 127 | 150 | 150 |

| Distance from spindle end to table surface | 160-565mm | 135-485mm | 200-600 (V) | 200-500(V) | |

| Distance from spindle center to table surface | 270-770mm | 0-350mm | 100-500mm | 0-300(H) 155-455 (V) | 0-300(H) 155-455 (V) |

| Spindle speed | 70-7200 (v) (20 steps) | 70-7200 (v) 20 steps | 80-5400 V | 70-7200 (V) (20 steps) | 70-7200 (V) (20steps) |

| 60-1800 (h) (12 steps) | 60-1800 (h) | 40-1300 H (12 steps) | 60-1350 H (12 steps) | 60-1350 H(12steps) | |

| Working table size | 1500/1630×360mm | 1250×360mm | 1250×320mm | 1250×320mm | 1250×320 |

| Working table stroke | 900/1000 × 340× 420mm | 1000×350×400 | 600×340mm | 800×300×300mm | 600×300×300 |

| T-type groove quantity and size | 3/18/80mm | 3-16mm-80mm | / | 3/14/70mm | 3/4/70 |

| Automatic feed (X, Y) | 30-630mm/min. | 22-555mm/min. | / | / | / |

| Fast feed (X, Y) | 2000mm/min. | 700mm/min. | / | / | / |

| Up-down speed (Z) | 666mm/min. | 540mm/min. | / | / | / |

| Motor power | 3.7/5HP (V) 4.0 (H) | 4.0 (H) 3.7(V)/5.5 (optional) | 2.2 (V)/3 (H) | 3.7 (V)/2 (H) | 3.7(V) / 2 (H) |

| Feeding motor | 1500W | 750W | / | / | / |

| Cooling motor power | 60 | / | / | / | |

| Packing size | 2000×2080×2250mm | 2000×1750×2200mm | 1520×1630×2200mm | 2000×2200×2250mm | 1700×1520×2260 |

| Net/gross weight | 3000/3100kg | 2600/2750kg | 1550/1700kg | 1850/2050kg | 1750/1950 |

| Item | UT432D | UT426 | |

| Working table size | 1250×320mm | 1270×260mm | |

| Working table stroke | 800×300×300mm | 700×280×450mm | |

| Spindle speed | Low (r/min.) | 80-2720 | 80, 135, 210, 325, 660, 1110, 1750, 2720 |

| High (r/min.) | 160-5400 | 160, 270, 420, 650, 1320, 2220, 3500, 5400 | |

| Spindle | Taper (mm) | ISO 30 R8 ISO 40 | NT30 R8 NT40 |

| Drilling diameter (mm) | 15 | 15 | |

| Sleeve stroke (mm) | 127 | 27 | |

| Cutter head | Horizontal rotation | ±90° | ±90° |

| Backward and forward rotation | ±45° | ±45° | |

| Main motor | Voltage | 380V | 380V |

| Frequency | 50Hz | 50Hz | |

| Motor | 3HP | 3HP | |

| Distance from spindle center to table surface (mm) | 100-490 | 100-490 | |

| Packing size (mm) | 1655×1650×2300 | 1655×1650×2300 | |

Related Names

Radial Arm Milling Machine | Precision Milling Equipment | Metal Working Machine

Links:https://www.globefindpro.com/products/81376.html

-

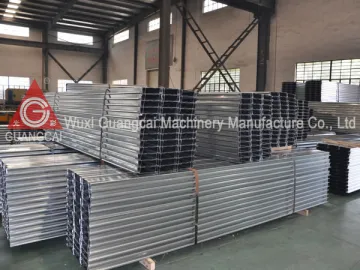

GWC65-185-555 Floor Deck Roll Forming Machine

GWC65-185-555 Floor Deck Roll Forming Machine

-

Guide Rail Roll Forming Machine

Guide Rail Roll Forming Machine

-

GWC25-205-1025 Roof Panel Embossing and Roll Forming Machine

GWC25-205-1025 Roof Panel Embossing and Roll Forming Machine

-

GWC15-1239 Beaver Roof Tile Roll Forming Machine

GWC15-1239 Beaver Roof Tile Roll Forming Machine

-

Wall Panel

Wall Panel

-

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine

-

Hydraulic Press Brake

Hydraulic Press Brake

-

Hydraulic Automatic Feed Pipe Cutting Circular Saw

Hydraulic Automatic Feed Pipe Cutting Circular Saw

-

Mechanical Ironworker

Mechanical Ironworker

-

Hydraulic Slotting Machine

Hydraulic Slotting Machine

-

Mechanical Slotting Machine

Mechanical Slotting Machine

-

Hydraulic Punching Machine

Hydraulic Punching Machine