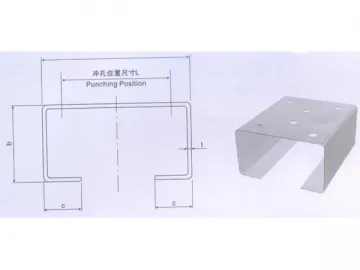

GWC M Purlin Roll Forming Machine

Common Features

1. By adjusting the spacer, the purlin roll forming machine is able to produce six kinds of products with different specifications.

2. It adopts stepless variable speed drive, including manual type and automatic type, to fabricate different purlin panels, ensuring high precision and stable performance.

3. According to the customer's requirements, there are three options for the production process which are pre-punching and pre-cutting type (punching – cutting- pressing), pre-punching and post-cutting type (punching – pressing - cutting), as well as post-punching and post cutting type (pressing – punching - cutting).

4. Our purlin roll forming machine can be designed according to the drawings and requirements provided by our client.

Processing Flow

Passive decoiling → guided material feeding → roll forming → punching → cut-to-length → offloading

Composition

1. 3T passive decoiler

2. Shape forming machine

3. Hydraulic shear

4. Hydraulic station

5. Punching machine

6. PLC control cabinet

7. Run out table

Specifications

| Product | GWC M purlin roll forming machine | Note |

| Applicable material | Galvanized sheet and color plate | This machine is customizable upon each customer's requirements and the characteristics of processed material. |

| Feeding width | 185mm | |

| Processing thickness | 0.4-1.0mm | |

| Roller material | Heat treated bearing steel | |

| Main motor power / hydraulic station power | 5.5kW / 3kW | These parameters can be set according to the required production capacity. |

| Forming passes | 16 | |

| Forming speed | 5-15 meters/minute | |

| Machine dimensions | 6.5×1.3×1.2m | |

| Machine weight | 4T |

Related Names

Pressed Steel Frame Forming Machine | Metal Building Purlin Machine | Structural Steel Channel Equipment

Links:https://www.globefindpro.com/products/81386.html

-

Road Beam Roll Forming Line

Road Beam Roll Forming Line

-

Automobile Chassis Roll Forming Machine

Automobile Chassis Roll Forming Machine

-

Stacker

Stacker

-

K-span Roll Forming Machine

K-span Roll Forming Machine

-

Bemo Panel Roll Forming Machine

Bemo Panel Roll Forming Machine

-

Carriage Board Roll Forming Machine

Carriage Board Roll Forming Machine

-

GWC900-820 Double Layer Roof Panel Roll Forming Machine

GWC900-820 Double Layer Roof Panel Roll Forming Machine

-

Purlin

Purlin

-

Roof Panel Bending Machine

Roof Panel Bending Machine

-

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine

-

Wall Panel

Wall Panel

-

GWC15-1239 Beaver Roof Tile Roll Forming Machine

GWC15-1239 Beaver Roof Tile Roll Forming Machine