Asphalt Paver Replacement Parts

HT-HI castings are produced with an abrasion resistant iron with a minimum of 550 brinell hardness. The lifespan of our asphalt paver replacement parts is more than twice as long as that of ordinary wear-resistant parts. Most of the world’s leading OEMs and 1st tier suppliers in concrete construction, paving machine, crusher, vertical mill and other demanding markets continue to rely on HT-HI because we provide the capability to meet exacting demands, the capacity to handle high volumes, the value-adds to shorten the supply chain and the expertise and agility to evolve with changing needs.

We offer the following castings

Auger Blade Bottom Wear Plate

Casting Wear Ring

Paver Brands Supported

China: XCMG, SANY, ZOOMLION

Other: VOGELE, VOLVO, DYNAPAC, DEMAG, WIRTGEN, BENNINGHOVEN

Material Standards

Casting steel: DIN, JIS, EN, ASTM, GB

White chromium alloy castings: Cr content of 8%-29%

Ni hard cast iron: containing 2-6%

Manganese steels: with a Mn content of 13%-19%

Low alloy martensitic steels

Examples of our work:

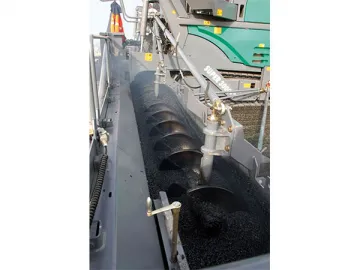

Paver auger blade

Paver auger blade

Why choose us

HT-HI is currently the Chinese largest manufacturer of wear-resistant parts for both concrete and asphalt mixing machines. Each year we can produce 20,000 tons of abrasion-resistant Cr/Mn hard cast iron castings. Our manufacturing complex spans a total area of 58,000 square meters. We use 6 large production workshops and fully automatic machines to guarantee both the production efficiency and product quality.

More Info

Precise mold making: We use the most advanced 3D simulation PROCAST & Solidworks 3D software to ensure a high-precision mold making and casting process. Advanced technology: HT-HI avails itself of DISA vertical automated moulding installations for green sand moulding and chemical moulding, recycling of moulding sands of a mechanical and thermal type, smelting in MF electric induction furnaces, shot blast systems, natural gas heat treatment furnaces, deburring machines and machining equipment based on CNC technology. Constant-temperature casting: Toshiba constant-temperature casting control system and patented filter screen provide a guarantee on constant-temperature casting. Strict quality control: Direct-reading spectrometers from Thermo Fisher and Barid are used to control the quality of our products in the manufacturing process.

Health and safety is at the center of everything we do, from the daily routines in our plants to our customers’ project worksites.

Material Standards

Links:https://www.globefindpro.com/products/8141.html

-

MF NSF highbay lights

MF NSF highbay lights

-

LED Tri-proof Light

LED Tri-proof Light

-

Vertical Mill Grinding Balls

Vertical Mill Grinding Balls

-

LFT738 Optical Film Peeling Gluing Slitting Machine

LFT738 Optical Film Peeling Gluing Slitting Machine

-

LED Panel Light

LED Panel Light

-

LED Tri-proof Light Eco

LED Tri-proof Light Eco

-

Slitter Rewinder Machine, 300m/min, LFS426

Slitter Rewinder Machine, 300m/min, LFS426

-

LED Track Light

LED Track Light

-

MF zoomable UFO high bay lights

MF zoomable UFO high bay lights

-

LED Wall Pack Light

LED Wall Pack Light

-

MF-FL LED Flood light

MF-FL LED Flood light

-

LED Stadium Light

LED Stadium Light