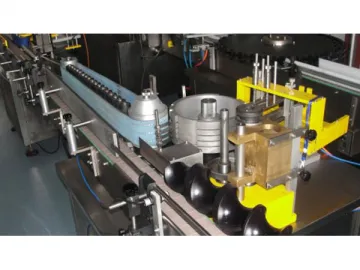

Automatic Rotary Capping Machine

Introduction to the Automatic Rotary Capping Machine

1. YXT-XG automatic rotary capping machine is formed for the automatic capping, cap screwing, or thread rolling in the sectors, such as pharmaceutical industry, food, chemical industry, and so forth. It can function as a glass bottle capper.

2. Due to the round disc positioning, this rotary capper suits to bottles of different sizes and materials. Rationally structured, our equipment of compact structure can be used with other equipment to form a production line.

Features of the Automatic Rotary Capping Machine

1. The automatic rotary capping machine runs stably by using the frequency control. It doesn’t make any noise. You can conveniently operate and maintain the vial cap sealing machine.

2. This equipment has the automatic display and counting function. Its magnetic moment for screwing cover is adjustable. No chippings will be produced.

3. Our cap tightener is designed for continuous, automatic operation. That means it helps you save time and improve efficiency.

4. Its design satisfies the requirements of GMP.

Parameters of the Automatic Rotary Capping Machine

| Item | XG-6, XG-8 |

| Specifications of Bottles | 20-1,000ml |

| Number of Capping Head | 6, 8 |

| Size of Thread Cap | ¢12-70mm |

| Size of ROPP | ¢16-36mm |

| Speed of Capping | 6,000-8,000 bottles per hour, 7,500-10,000 bottles per hour |

| Successful Rate of Rotary Capping | ≥99% |

| Power Supply | 380V/220V 50Hz |

| Net Weight | About1200kg |

| Overall Dimensions | 3,500*1,200*2,000mm |

| Air Consumption | 20M3/h |

Links:https://www.globefindpro.com/products/81573.html

-

Small Dose Bottle Filling and Capping Machine

Small Dose Bottle Filling and Capping Machine

-

Automatic Gravity Filling Machine

Automatic Gravity Filling Machine

-

Packing System Conveyor

Packing System Conveyor

-

Steam Shrink Tunnel

Steam Shrink Tunnel

-

Low Vacuum Bottling Line

Low Vacuum Bottling Line

-

Horizontal Labeling Machine

Horizontal Labeling Machine

-

6 Filling Head and 1 Capping Head Packaging Machine

6 Filling Head and 1 Capping Head Packaging Machine

-

Inkjet Printer

Inkjet Printer

-

Automatic Double Head Capping Machine

Automatic Double Head Capping Machine

-

Automatic Six Head Aluminum Capping Machine

Automatic Six Head Aluminum Capping Machine

-

Single Side Glue Labeling Machine

Single Side Glue Labeling Machine

-

High Viscosity Liquid Filling Machine

High Viscosity Liquid Filling Machine