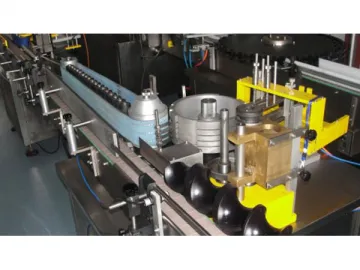

Small Dose Bottle Filling and Capping Machine

Introduction

YXT-YGB small dose bottle filling and capping machine is the main machine unit in the oral liquid production line. It is primarily used for 10ml to 20ml straight tube bottle.

Features of the Small Dose Bottle Filling and Capping Machine

1. Controlled by Mitsubishi variable-frequency and variable-speed motor, the small dose bottle filling and capping machine is convenient, stable in operation.

2. This product has a wide application range. It can be used for round bottles, square bottles, flat bottles, and other shaped bottles.

3. The bottle filler capper can be freely adjusted within the adjustment range, according to the size of the bottles and caps.

4. In general applications, the small dose bottle filling and capping machine applies the stainless steel plunger pump. In the case of corrosive liquid, it uses the volumetric ceramic pump for filling.

5. Ceramic pump filling system absorbs no drugs. It has good chemical stability with excellent resistance to high temperature, corrosion, and abrasion. That is why it has a long service life.

6. The entire YXT-YGB equipment adopts the low level liquid storage bucket. It is easy in cleaning, convenient in sterilization.

7. Since the filling needle can get into the bottle for filling, our machine has no leakage problems and suits to fill all sorts of viscosity liquid. That the filling needle reaches to the bottle bottom for filling and then slowly ascends can effectively prevent bubbling.

8. Definitely, this vial filling and sealing machine is made as requested by GMP standards.

Parameters of the Small Dose Bottle Filling and Capping Machine

| Size of Bottles | 15-100ml |

| Voltage/Power | 220V/1.2Kw |

| Capacity | Double head filling, single head capping: 2000-3000 bottles per hour; Four head filling, double head capping: 3600-4800 bottles per hour |

| Filling Accuracy | ≤±1% (standard filling amount) |

| Yield of Cap-rotating | ≥99% |

Links:https://www.globefindpro.com/products/81574.html

-

Automatic Gravity Filling Machine

Automatic Gravity Filling Machine

-

Packing System Conveyor

Packing System Conveyor

-

Steam Shrink Tunnel

Steam Shrink Tunnel

-

Low Vacuum Bottling Line

Low Vacuum Bottling Line

-

Horizontal Labeling Machine

Horizontal Labeling Machine

-

Four Filling Head and One Capping Head Packing Machine

Four Filling Head and One Capping Head Packing Machine

-

Automatic Rotary Capping Machine

Automatic Rotary Capping Machine

-

6 Filling Head and 1 Capping Head Packaging Machine

6 Filling Head and 1 Capping Head Packaging Machine

-

Inkjet Printer

Inkjet Printer

-

Automatic Double Head Capping Machine

Automatic Double Head Capping Machine

-

Automatic Six Head Aluminum Capping Machine

Automatic Six Head Aluminum Capping Machine

-

Single Side Glue Labeling Machine

Single Side Glue Labeling Machine