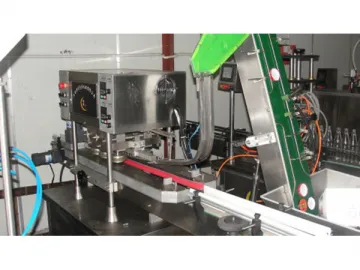

Air-Cooled Aluminum Foil Sealing Machine

Working Principle of the Air-Cooled Aluminum Foil Sealing Machine

1. YXT-AB air-cooled aluminum foil sealing machine is a bottle sealer that works based on the electromagnetic induction principle. The high frequency signal after enlarged will be output by the induction coil.

2. When the container which is equipped with compound aluminum foil gasket comes across the induction coil, the eddy current will be instantly formed to generate heat that will bond aluminum foil and bottle mouth. Thereby, the hermetic sealing effect is achieved.

Features of the Air-Cooled Aluminum Foil Sealing Machine

1. Through the adoption of American technology and transistor module design, the air-cooled aluminum foil sealing machine offers high working efficiency with low failure rate. All of its technical indexes are of national advanced level.

2. The induction sealer is appropriate for the sealing of PE, PET, PP, glass, or other non-metal containers used in the areas including medicine, food, cosmetics, farm chemicals, oil products, etc. It also has the anti-fake, anti-theft functions.

3. This sealing equipment works speedily.

Parameters of the Air-Cooled Aluminum Foil Sealing Machine

| Model | YXT-AB3 |

| Rated Voltage | AC220V ( 10%) |

| Output Power | 1KW-4KW (You can choose the output power as you like.) |

| Working Frequency | 100KHZ ( 10%) |

| Static Power Consumption | 2.5A |

| Max. Supply Current of Single Unit | 5A |

| Working Environment Temperature | 5 to45℃ |

| Sealing Diameter | 60 to120mm |

| Suitable Film | Dedicated sensing film, aluminum foil film (not suitable for vacuum aluminum plating film) |

| Sealing Speed | 50 to 150 bottles per minute |

| Overall Dimension | 1400*1000*500 (L * H * W) |

Links:https://www.globefindpro.com/products/81585.html

-

Isobaric Bottling Line

Isobaric Bottling Line

-

Double Side Labeling Machine

Double Side Labeling Machine

-

Roll-over Bottle Rinser

Roll-over Bottle Rinser

-

Automatic Screw Capping Machine

Automatic Screw Capping Machine

-

Automatic Round Bottle Labeling Machine

Automatic Round Bottle Labeling Machine

-

Automatic Single Head Aluminum Capping Machine

Automatic Single Head Aluminum Capping Machine

-

Flat Bottle Labeling Machine

Flat Bottle Labeling Machine

-

Four Filling Head Capping Machine

Four Filling Head Capping Machine

-

Automatic Press Capping Machine

Automatic Press Capping Machine

-

Carton Sealer

Carton Sealer

-

Four Filling Head and One Capping Head Packing Machine

Four Filling Head and One Capping Head Packing Machine

-

Horizontal Labeling Machine

Horizontal Labeling Machine