Protection Spirals for Ball Screws

Performance

Our protection spiral is a machine tool component jointly developed by us and one Italian company, with unique functions to protect NC lathe, machining center, hydraulic machine tool, various shafts, rods, and ball screws from chips, dust, and liquid damages. It also enables precision operation and increased service life of machine tool in addition to adding decorative touches to the equipment.

Structures

This series of protection spiral is made of premium spring steel strips that have been sent through heat treatment. It is usually installed onto the flanges at both ends of protected parts, forming a non-contact connection with the parts. Elastic force produced by the pre-stressed spiral acts on the connection, ensuring a secure joint. During operation, the spiral freely extends or compresses while creating little noise. Its black color goes well with most of the flange parts on the machine tool.

Ordering Instruction

This series of product can be customized, based on the diameter of ball screws, shafts, and rods as well as travel distance. So it would be important to know the following ordering method.

1. Clients should select the products according to the standard specifications provided by our company.

2. If our clients have special requirements on D, Lmax, and Lmin, please let us know by writing down the specifications in the D2 column of the following table. According to their data, we will design and manufacture the most suitable product, all available at the same price with the standard ones.

Note

1. We can provide technical drawing to customers who want use the spiral on the flange.

2. We offer discounts for bulk purchases.

3. There is little limit to the specifications that we can provide.

| LGB | Lmax mm | Lmix mm | D1 mm | D2(mm) Specifications for Reference | LGB | Lmax mm | Lmin mm | D1 mm | D2(mm) Specifications for Reference |

| Specifications | Specifications | ||||||||

| 20-250-30 | 250 | 30 | 20 | 40 | 70-400-80 | 400 | 80 | 70 | 95 |

| 30-250-45 | 250 | 45 | 30 | 41 | 70-750-100 | 750 | 100 | 70 | 94 |

| 30-450-50 | 450 | 50 | 30 | 50 | 70-1400-120 | 1400 | 120 | 70 | 104 |

| 30-600-50 | 660 | 50 | 30 | 56 | 70-1800-120 | 1800 | 120 | 70 | 120 |

| 40-300-45 | 300 | 45 | 40 | 54 | 75-400-80 | 400 | 80 | 75 | 89 |

| 40-550-50 | 550 | 50 | 40 | 67 | 75-600-100 | 600 | 100 | 75 | 95 |

| 40-800-80 | 800 | 80 | 40 | 65 | 75-900-120 | 900 | 120 | 75 | 97 |

| 40-950-80 | 950 | 80 | 40 | 69 | 75-1200-120 | 1200 | 120 | 75 | 104 |

| 45-550-50 | 550 | 50 | 45 | 73 | 75-1600-1100 | 1600 | 110 | 75 | 115 |

| 45-700-80 | 700 | 80 | 45 | 68 | 80-400-80 | 400 | 80 | 80 | 94 |

| 45-900-100 | 900 | 100 | 45 | 70 | 80-600-120 | 600 | 120 | 80 | 97 |

| 45-1000-100 | 1000 | 100 | 45 | 73 | 80-900-110 | 900 | 110 | 80 | 105 |

| 50-500-50 | 500 | 50 | 50 | 72 | 80-1200-120 | 1200 | 120 | 80 | 115 |

| 50-700-80 | 700 | 80 | 50 | 70 | 80-1400-120 | 1400 | 120 | 80 | 120 |

| 50-900-100 | 900 | 100 | 50 | 77 | 85-400-80 | 400 | 80 | 85 | 100 |

| 45-1200-100 | 1200 | 100 | 50 | 84 | 85-600-100 | 600 | 100 | 85 | 105 |

| 55-350-50 | 350 | 50 | 55 | 72 | 85-800-125 | 800 | 125 | 85 | 106 |

| 55-550-80 | 550 | 80 | 55 | 72 | 85-1000-125 | 1000 | 125 | 85 | 126 |

| 55-800-80 | 800 | 80 | 55 | 78 | 85-1200-125 | 1200 | 125 | 85 | 132 |

| 55-1000-120 | 1000 | 120 | 55 | 77 | 90-400-100 | 400 | 100 | 90 | 105 |

| 55-1400-110 | 1400 | 110 | 55 | 86 | 90-600-100 | 600 | 100 | 90 | 111 |

| 60-400-50 | 400 | 50 | 60 | 79 | 90-800-125 | 800 | 125 | 90 | 111 |

| 60-600-80 | 600 | 80 | 60 | 78 | 90-900-125 | 900 | 125 | 90 | 127 |

| 60-900-100 | 900 | 100 | 60 | 87 | 90-1200-125 | 1200 | 125 | 90 | 137 |

| 60-1200-120 | 1200 | 120 | 60 | 88 | 95-400-100 | 400 | 100 | 95 | 110 |

| 60-1600-120 | 1600 | 120 | 60 | 98 | 95-600-125 | 600 | 125 | 95 | 112 |

| 65-400-50 | 400 | 50 | 65 | 85 | 95-800-125 | 800 | 125 | 95 | 130 |

| 65-700-80 | 700 | 80 | 65 | 87 | 95-1000-125 | 1000 | 125 | 95 | 137 |

| 65-1000-100 | 1000 | 100 | 65 | 95 | 100-600-120 | 600 | 120 | 100 | 118 |

| 65-1400-110 | 1400 | 110 | 65 | 99 | 100-800-125 | 800 | 125 | 100 | 135 |

| 65-1800-110 | 1800 | 110 | 65 | 109 | 120-600-125 | 600 | 125 | 120 | 150 |

Dl-Inner Diameter of the Smaller End of Protection Spiral =Dmax 10mm

D2- Inner Diameter of the Bigger End of Protection Spiral

D3- Outside Diameter of the Bigger End of the Flange=D2 6~8mm

D4- Outside Diameter of the Bigger End of the Flange =D1 1 ~ 2mm

Dmax-Maximum Diameter of Protected Parts

Lmin-Fully Compressed Length

Lmax-Fully Extended Length

Maximum Allowable Distance

Related Names

Protective Enclosure | Protection Tubing | Miniature Shield

Links:https://www.globefindpro.com/products/81644.html

-

S85 Series Heavy Duty Adjustable Machine Mounts

S85 Series Heavy Duty Adjustable Machine Mounts

-

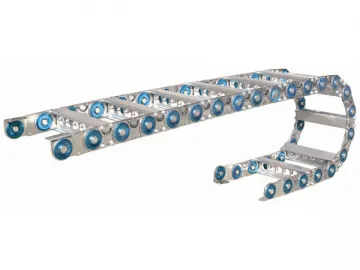

TLG Series Steel Cable Drag Chains

TLG Series Steel Cable Drag Chains

-

TEZ(D) Series Loading-Bearing and Over-Length Engineering Plastic Cable Drag Chains

TEZ(D) Series Loading-Bearing and Over-Length Engineering Plastic Cable Drag Chains

-

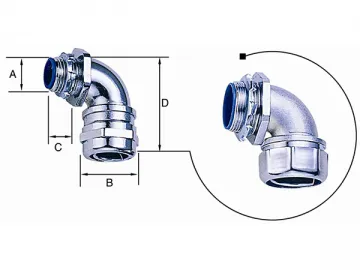

Water-proof Hose Connector

Water-proof Hose Connector

-

510 E Cigarette

510 E Cigarette

-

SKC E Cig

SKC E Cig

-

Brother-C ECigarette

Brother-C ECigarette

-

E Cigarette Carrying Case

E Cigarette Carrying Case

-

eGo LCD Batteries

eGo LCD Batteries

-

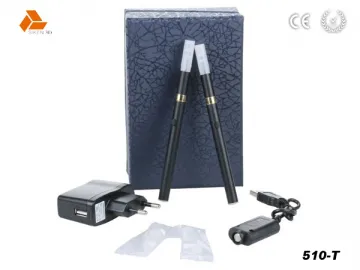

510-T E Cigarette

510-T E Cigarette

-

Scraper Type Chip Conveyor

Scraper Type Chip Conveyor

-

eGo-Twist Batteries

eGo-Twist Batteries