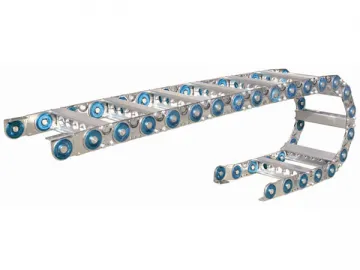

TLG Series Steel Cable Drag Chains

Our TLG series drag chain is made of steel, allowing an increase in the number and weight of cables as well as oil hoses carried. Its self-supporting structure eliminates the need to use rollers for support, and upon special request is available with a cable separator plate installed into the chain chamber. Extra long design is suitable for use on the machine tool or moving equipment.

Different drag chain models offer choices of bending radii ranging from 75mm to 600mm and side plate heights between 50mm and 150mm. Designed to accommodate almost all transmission modes, this series of cable carrier has a maximum traversing distance of 32m. Its length can be made longer or shorter, depending on the practical need. Plus, its bending radius can be changed by making alterations to the dowel pin.

The optional cable separator plate has a width range between 50mm and 500mm. Distance between holes in the plate is 5mm. These holes allow cables or oil hoses to pass through in the drag chain chamber, allowing organized cable separation. The height of separator is determined with reference to the maximum diameter of cables. When the machine tool operates at its maximum speed, if the chain width exceeds the limit of 300mm or length is more than 4m, users need to consider replacing the drag chain with a bigger one to allow more space for cables to move.

Bending radius should be ten times the maximum diameter of the cable. It is available in a range between 50mm and 600mm. When the traversing distance is getting shorter, the bending radius should be adjusted smaller associatively.

Proper chain length equals to half of the maximum traversing distance plus 4 times of bending radius. This formula only applies to the situation where the fixed end of the chain is located underneath the middle of the whole chain length. Depending on the location of the machine tool, the chain can be fixed in different positions. Users can use a mounting bracket to fixate the chain to the machine tool. The mounting bracket can be placed inside or outside the chain. However, it is generally the case that the bracket is installed inside the drag chain, facing outward.

Main Parameters

| Model | Bending Radius | Pitch | a | c | d | e | f | g | h | k | Self-Supporting | Weight 100mm | |

| Length | Load Bearing Capacity Kg/m | ||||||||||||

| TLG10 | 50/100/150/200 | 50 | 19 | 35 | 5.5 | 3 | 20 | 7.5 | 7 | 9.5 | 3 | 4 | 2.30 |

| TLG20 | 75/100/150/200/250/300 | 75 | 31 | 50 | 8 | 4 | 30 | 12 | 9 | 15 | 3/2/2 | 20/30/30 | 4.90/4.80/5.50 |

| TLG30 | 100/150/200/250/300/400 | 100 | 49 | 75 | 10 | 4 | 50 | 17 | 11 | 21 | 4/3/3 | 25/40/40 | 9.10/9.10/10.00 |

| TLG40 | 200/250/300/400/500 | 125 | 68 | 100 | 14 | 4 | 70 | 22 | 13 | 28 | 6/4/4 | 30/50/50 | 18.10/18.10/19.30 |

| TLG50 | 250/300/400/500/600 | 175 | 118 | 150 | 14 | 8 | 115 | 26 | 13 | 32 | 10/8 | 10/30 | 25.00 |

Order Example: 11.2m maximum traversing distance, 300mm bending radius, proper sizes to accommodate 3 cables with a diameter of 48mm apiece, 2 cables with a diameter of 28mm apiece, and 2 hoses with a diameter of 36mm apiece.

Related Names

Heavy Steel Chain | Carrier Chain | Flat Conveyor Chain

Links:https://www.globefindpro.com/products/81646.html

-

TEZ(D) Series Loading-Bearing and Over-Length Engineering Plastic Cable Drag Chains

TEZ(D) Series Loading-Bearing and Over-Length Engineering Plastic Cable Drag Chains

-

Water-proof Hose Connector

Water-proof Hose Connector

-

510 E Cigarette

510 E Cigarette

-

SKC E Cig

SKC E Cig

-

Magnetic Chip Conveyor

Magnetic Chip Conveyor

-

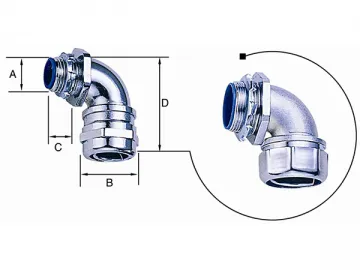

Right Angle Hose Connector

Right Angle Hose Connector

-

S85 Series Heavy Duty Adjustable Machine Mounts

S85 Series Heavy Duty Adjustable Machine Mounts

-

Protection Spirals for Ball Screws

Protection Spirals for Ball Screws

-

Brother-C ECigarette

Brother-C ECigarette

-

E Cigarette Carrying Case

E Cigarette Carrying Case

-

eGo LCD Batteries

eGo LCD Batteries

-

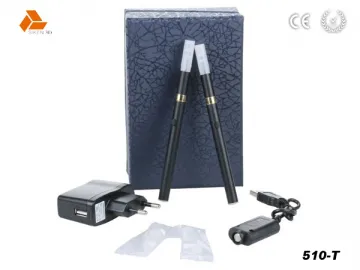

510-T E Cigarette

510-T E Cigarette