Screw Chip Conveyor

Our screw chip conveyor is most often used to cope with various metal or non-metal powders, particles, and chips. It is available in different types listed as follows:

Type A: with helical screw core and chip collection trough

Type B: with helical screw core but without chip collection trough

Type C: with chip collection trough but without helical screw core

Type D: without helical screw core and chip collection trough

Each type of chip conveyor can be used in combination with other dust removal devices to form various dust removal systems.

Features

1. Easy installation

2. Reliable functioning

3. Wide range of processing speeds

4. Customizable

| HRLX Series |

Applications

Used on various machine tools and for applications with narrow spaces.

| Model | Helical Blade Diameter D | Helical Blade Pitch P | Overall Length L | Chip Removal Rate C |

| HRLX-80 | 80 | 72 | Customizable | 150 |

| HRLX-100 | 100 | 100 | 180 | |

| HRLX-120 | 120 | 122 | 210 |

YSLX Series

Models: YSLX70, YSLX80, YSLX100, YSLX150, YSLX200.

Note for Ordering

Please select the model and determine the conveyor length.

| Model | Helical Screw Diameter D | Chip Collection Trough B | Helical Screw Blade Pitch P | R | H | L | Motor Power kw | Chip Removal Rate kg/h |

| YSLX70 | 70 | 90 | 80 | 45 | Customizable | 0.60-3.00 | 0.10 | 70--100 |

| YSLX80 | 80 | 100 | 80 | 50 | 0.60-5.00 | 0.10-0.37 | 90-130 | |

| YSLX100 | 100 | 120 | 100 | 60 | 0.80-6.00 | 0.10-0.75 | 120-180 | |

| YSLX150 | 150 | 180 | 100 | 90 | 1.00-10.00 | 0.10-0.75 | 150-220 |

Related Names

Automated Conveyor | Spiral Conveying Machine | Mechanical Conveyer

Links:https://www.globefindpro.com/products/81665.html

-

Hand Knob

Hand Knob

-

Plane Dial Hand Wheel

Plane Dial Hand Wheel

-

Adjustable Coolant Hose

Adjustable Coolant Hose

-

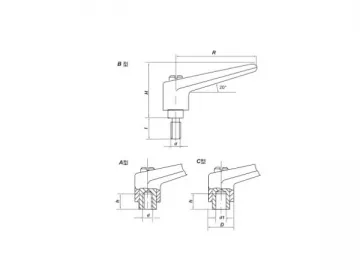

Adjustable Clamping Lever

Adjustable Clamping Lever

-

Fluted Dial Hand wheel

Fluted Dial Hand wheel

-

Incandescent Machine Light

Incandescent Machine Light

-

Telescopic Steel Cover for Machine Slide

Telescopic Steel Cover for Machine Slide

-

TLZ Series Loading-Bearing and Over-Length Engineering Plastic Cable Drag Chains

TLZ Series Loading-Bearing and Over-Length Engineering Plastic Cable Drag Chains

-

Armoured Vertical Bellows for Machine Tools

Armoured Vertical Bellows for Machine Tools

-

Reinforced Round Bellows

Reinforced Round Bellows

-

Volt Batteries

Volt Batteries

-

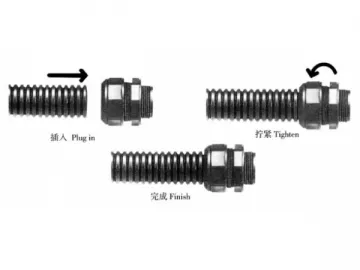

Screw-on Hose Connector

Screw-on Hose Connector