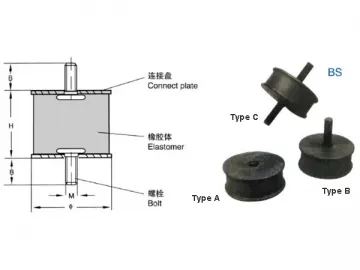

S78 Series Advanced Anti Vibration Mounts

Features

Our S78 series advanced anti vibration mount features a vibration damping base or load bearing plate that is made of nitrile rubber. Rubber is resistant to oil and cooling agent. It has been proven to be an effective material to damp machine vibration, reduce the amount of vibration that transfers beyond the machine into the floor, and prevent external source vibration entering the machine. It isolates the machine from transferring vibration force and noise generated by the oscillating motion, thereby ensuring the machining precision and quality. This also makes it possible for various rough and precision machine tools combining into an integrated production unit so as to keep pace with the latest development in material handling technology.

This anti vibration mounts also can be easily installed onto the machine tool without the need for bolts to fix the mount to ground. Simply mounting your machine tool onto our mount is all you need to do, as the mount will make the whole structure stand firmly on the floor while giving good vibration-damping and deformation-resistant performance, even under heavy load. Using our mount just means cutting down on your installation cost and time. With this mount, users can freely change the position where they decide to put their machine tool without the need for repeated installation.

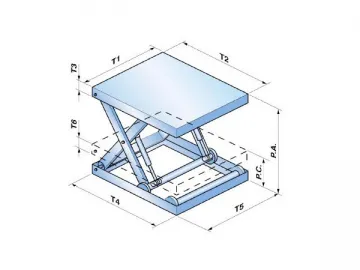

The anti vibration mount provides the added benefit of leveling the equipment as well. It allows a wide range of leveling adjustments in a fast, convenient fashion.

Applications

Metalworking machine tool, forging press, textile machinery, printing machinery, food processing equipment, rubber manufacturing machinery, wire and cable processing machinery, packaging machinery, electricity generator and heavy-duty equipment.

Installation

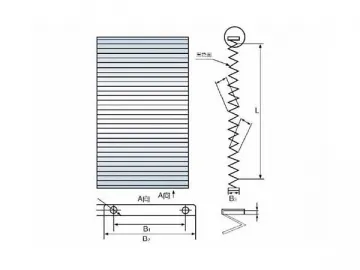

Position the anti-vibration mount underneath the machine tool. Make bolt holes of the mount aligned with holes of machine feet. Insert the bolt through bolt holes in the machine feet and into the bolt holes in the machine mount. Then turn the bolt to ensure a tight connection between the machine feet and the machine mount. Level the machine tool by turning the bolt in clockwise direction so as to elevate the machine tool. After the leveling work is finished, tighten the lock nut. If the new machine mount is used for the first time, creep deformation might occur under the influence of stresses. Please remember to level the machine tool after two weeks of use.

| Product Reference Number | Rubber Hardness | Dimensions | Bolt | Adjustable Height | Static Load Bearing Capacity per Machine Mount | Nominal Values | ||

| (mm) | (mm) | (mm) | ||||||

| ø-H-Sh | (A) ×3 | 0 | H | M | h | Fmax (N) | Sz (mm) | fz (Hz) |

| S78 040-15-50 | 50 | 40 | 15 | M5×30 | 5 | 250 | 1.4 | 13 |

| S78 080-25-50 | 50 | 80 | 25 | M10×80 | 8 | 1000 | 2.8 | 9.4 |

| 080-25-60 | 60 | 1700 | ||||||

| 080-25-70 | 70 | 2500 | ||||||

| S78 120-32-50 | 50 | 120 | 32 | M12×100 | 12 | 4000 | 3.2 | 8.8 |

| 120-32-60 | 60 | 5500 | ||||||

| 120-32-70 | 70 | 8500 | ||||||

| 120-32-80 | 80 | 12000 | ||||||

| S78 160-35-50 | 50 | 160 | 35 | M16×120 | 12 | 10000 | 3.3 | 8.7 |

| 160-35-60 | 60 | (M20) | 19000 | |||||

| 160-35-70 | 70 | 24000 | ||||||

| 160-35-80 | 80 | 35000 | ||||||

| S78 185-39-60 | 60 | 185 | 39 | M20× 2.5×160 | 12 | 22000 | 3.6 | 8.3 |

| 185-39-70 | 70 | (M16) | 31000 | |||||

| 185-39-80 | 80 | 42000 | ||||||

| S78 228-54-60 | 60 | 228 | 54 | M24×3 × 180 | 12 | 33000 | 4.5 | 7.5 |

| 228-54-70 | 70 | (M20) | 43000 | |||||

| 228-54-80 | 80 | 65000 | ||||||

| S78 315-70-70 | 70 | 315 | 70 | M30×3.5× 180 | 12 | 75000 | 6 | 6.4 |

| 315-70-80 | 80 | (M30) | 95000 | |||||

Note

1. The length of the bolt can be adjusted to customer specific requirements.

2. If your machine tool feet has no bolt holes where we can install our machine mount, you can order specialized attachments.

3. Sz= Amount of deformation along Z-axis under maximum load.

4. Fz= Vibration frequency under maximum static load.

Related Names

Vibration Isolation Pad | Shock Vibration Mounts | Rubber Vibration Damper

Links:https://www.globefindpro.com/products/81704.html

-

S79 Series Advanced Anti Vibration Mounts

S79 Series Advanced Anti Vibration Mounts

-

Plastic-coated 3 Way Corrugated Hose

Plastic-coated 3 Way Corrugated Hose

-

Plastic Hex Nut

Plastic Hex Nut

-

Infrared Sensor Switch

Infrared Sensor Switch

-

Surface Plates

Surface Plates

-

Double Handles Hand Wheel

Double Handles Hand Wheel

-

Flexible Dust Collection Hose

Flexible Dust Collection Hose

-

Machine Vibration Damper

Machine Vibration Damper

-

Fixed Machine Leveling Feet

Fixed Machine Leveling Feet

-

Folding Concertina Bellow Slideway Covers

Folding Concertina Bellow Slideway Covers

-

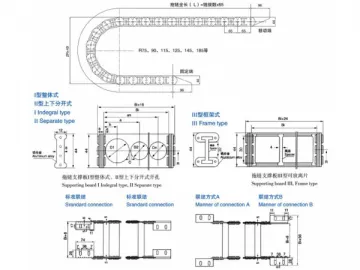

TL Series Steel Cable Drag Chains

TL Series Steel Cable Drag Chains

-

Square Type Machine Shield

Square Type Machine Shield