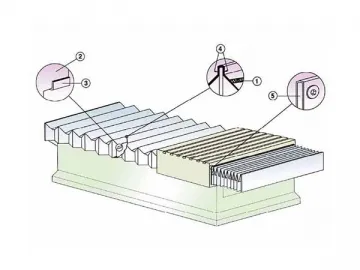

Thermit Welding Bellow Covers for Linear Slides

Our thermit welding bellow covers are most commonly used on the linear slides.

Examples

StandardMaterials

| Code | Support | Hood | Compressed Length (for bellows with an extended length of 1000mm) | Availability |

| S1 | PVC 0.50 | PVC Polyester PVC0.25(TEMAT020) | 90 | Ready to deliver |

| P1 | PVC 0.50 | Polyurethane Polyester Polyurethane | 90 | Ready to deliver |

| LX | PVC 1.00 | PANOX /Kevlar0.33 (TEMAT169) | 150 | Upon request |

Standard Size

| Nominal Value of Linear Slide W1 | Height per Fold X | Bellows Width W | Total Height H | Slideway Deviation h |

| 15 | 19 | 56 | 36 | 5 |

| 20 | 19 | 61 | 40.5 | 5 |

| 25 | 19 | 67 | 43 | 7.5 |

| 30 | 19 | 72 | 51 | 8 |

| 35 | 19 | 76.5 | 51 | 9 |

| 45 | 19 | 87.5 | 61 | 10 |

IdentificationCode Examples

| Slide Model | KUE |

| Nominal Value(W1) | 35 |

| Extended Length(Travel Length Compressed Length) | 1250 |

| Material Type | S1 |

Fastening Solution A: holdfast

This solution is ideally applied to customers who provide angle bracket or other forms of support to which the bellows are fixed in the 1, 2, 3, and 4 positions.

| Linear Slide Bearing | W | C | Number of Holes |

| 15 | 52 | 26 | 2 |

| 20 | 57 | 29 | 2 |

| 25 | 63 | 32 | 2 |

| 30 | 68 | 34 | 2 |

| 35 | 72 | 36 | 2 |

| 45 | 83 | 38 | 3 |

| 55 | 104 | 35 | 3 |

| 65 | 128 | 32 | 4 |

Fastening Solution B: Velcro Flange

Position 1: I. Fix the type-1 flange to the end of the slide rail.

II. Join the bellow covers tightly to the flange.

Position 2 and 3: I. Fasten the type-2 flange to the slide table with screw spikes

II. Keep the bellow covers in firm contact with the flange.

Position 4: I. Fix the type-2 flange to the angle bracket.

II. Push the bellow covers tightly against the type-2 standard flange.

Note

Fastening solutions applied to the 1-4 position are interchangeable with each other.

| Slide | W | H | C |

| 15 | 56 | 36 | 0 |

| 20 | 61 | 40.5 | 8 |

| 25 | 67 | 43 | 8 |

| 30 | 72 | 51 | 8 |

| 35 | 76.5 | 51 | 18 |

| 45 | 87.5 | 61 | 18 |

| 55 | 108 | 73 | 18 |

| 65 | 132 | 90 | 18 |

| H1 | C1 | No. of Holes |

| 42 | 26 | 2 |

| 46.5 | 29 | 2 |

| 46.5 | 32 | 2 |

| 54 | 34 | 2 |

| 53 | 36 | 2 |

| 62 | 28 | 3 |

| 69 | 35 | 3 |

Related Names

CNC Machine Bellows | Slideway Cover | Expansion Bellows

Links:https://www.globefindpro.com/products/81725.html

-

Universal Bellow Covers

Universal Bellow Covers

-

TLG Series Steel Cable Drag Chains with Stainless Steel Straps

TLG Series Steel Cable Drag Chains with Stainless Steel Straps

-

High Frequency Welded Bellow Covers

High Frequency Welded Bellow Covers

-

Steel Coil Pickling Shearing

Steel Coil Pickling Shearing

-

Q Series European Style Switch and Socket

Q Series European Style Switch and Socket

-

M Series European Style Switch and Socket

M Series European Style Switch and Socket

-

Y Series British Style Switch and Socket

Y Series British Style Switch and Socket

-

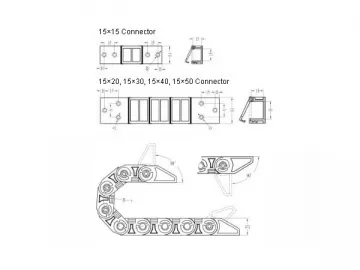

TEZ(F) Series Assembling Composite Loading-Bearing and Over-Length Engineering Plastic Cable Drag Chains

TEZ(F) Series Assembling Composite Loading-Bearing and Over-Length Engineering Plastic Cable Drag Chains

-

Hose Quick Connector

Hose Quick Connector

-

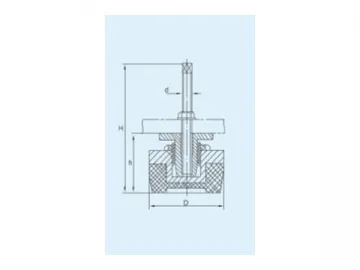

S77 Series Advanced Anti Vibration Mounts

S77 Series Advanced Anti Vibration Mounts

-

S78-8 Series Anti Vibration Mounts

S78-8 Series Anti Vibration Mounts

-

Standard Engineering Plastic Cable Drag Chains

Standard Engineering Plastic Cable Drag Chains