Steel Coil Slitting

Slitting Process Flow

Uncoiling --- Stretching-bending Rectifying --- Cleaning --- Slitting --- Inspection --- Coiling --- Subpackage

1. Uncoiling: Remove the steel coil package. Lift the steel coil with crane and put it onto the shearing equipment.

2. Stretching-bending Rectifying: Rectify the position of the ste plate for making sure the accuracy of steel plate position before shearing, thus guaranteeing the shearing precision.

3. Cleaning: Clean up the dust or other contaminants on the surface of steel plate.

4. Slitting: Slit the steel plate in accordance with the size that the customer requests.

5. Inspection: The quality controller checks the surface quality of the steel strip.

6. Coiling: Rewind the steel strip into a steel coil.

7. Subpackage: Package the steel coil.

Material

The material we can process covers cold rolled steel, electro-galvanized steel, hot-dipped galvanized steel, galvalume steel, color coated steel, electrical steel, and stainless steel.

Specification of Slitting Line

| Thickness of Material | 0.3mm~3.2 mm |

| Width of Material | 450mm~1650mm |

| Strip Number of Slitting | 0.3mm×30 strips ~3.2mm×8 strips |

| Strip Steel Tolerance | ± 0.05 mm |

| Max. Shear Strength | 560N/mm |

| Max. Yield Strength | 420N/mm |

| Min. Width of Finished Product | > 30mm |

| Max. Production Line Speed | 200 m/min |

| Outside Diameter of Steel Coil | 800mm ~ 2100mm |

| Inside Diameter of Steel Coil | 508mm / 610mm |

| Processing Capacity | 100,000 MT/year |

Components of Slitting Line

1. Coil Car

2. Shear

3. Loop Table

4. Uncoiler

5. Side Guide

6. Tension Station

7. Hold Down Roll

8. Slitter

9. Separator

10. Leveler

11. Scrap Winder

12. Recoiler

Advantage of Slitting Line

1. The equipment allows for high production and flow rates owing to the high production speed, minimization of set0up time, etc. It is superior in the following aspects.

a. Automatic steel coil feeding via steel coil height centering

b. Automatic cutter and tool change of the slitting shear

c. Automatic loop control

d. Ergonomic and simple exchange of separating shafts

e. Manual, semi-automatic and automatic strapping systems for strapping the steel coil at the circumference on the turnstile

f. Achieving automated and fast steel strip feeding from the slitting shear to the recoiler via the tension unit

2. The slitting line can ensure precise cutting accuracy for the cutter shaft is carried in multiple bearings.

3. It can achieve a large number of cuts simultaneously on the slitting shear with the cutting effect of little burr and the minimum deflection of the cutter shaft.

4. The slitting line realizes high accurate steel strip winding with the assistance of movable tension unit for the main operation and no need for separating device at the recoiler.

5. It is outfitted with the special braking system to coordinate the material surface to complete gentle treatment for the material with high-sensitive surface such as the lacquered steel strip and the bright annealed stainless steel.

6. By adoption of the exclusively components from the reputable manufacturers, the slitting line is provided with high line availability and long service lifetime.

7. The high-level automation degree allows that only fewer operating personnel can complete the processing work.

8. The prompt assistance is also available in case of need via our online service or the field service by out expert.

9. We design the slitting line flexibly in line with the requirements of customers and by taking the experience of customers into account.

Customers can get the exceptional service from us. Our product is worth buying for the comparative advantage.

Related Names

Steel Cutting Service | Steel Slitting Line | Sheet Metal Slitter

Links:https://www.globefindpro.com/products/81767.html

-

Electro-Galvanized Steel Coil (EGI)

Electro-Galvanized Steel Coil (EGI)

-

Steel Coil Cut-to-length

Steel Coil Cut-to-length

-

Hot-Dipped Galvanized Steel Coil (GI,HDG,CGI)

Hot-Dipped Galvanized Steel Coil (GI,HDG,CGI)

-

Tinplate (TP)

Tinplate (TP)

-

Stainless Steel Coil

Stainless Steel Coil

-

Pole Mount Satellite Dish

Pole Mount Satellite Dish

-

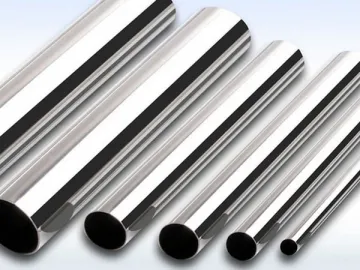

Stainless Steel Pipe

Stainless Steel Pipe

-

Hot Rolled Steel Coil (HR,HRC)

Hot Rolled Steel Coil (HR,HRC)

-

90cm Ku Band Satellite Dish

90cm Ku Band Satellite Dish

-

80cm Ku Band Satellite Dish

80cm Ku Band Satellite Dish

-

75cm Ku Band Satellite Dish

75cm Ku Band Satellite Dish

-

O Series Switch and Socket

O Series Switch and Socket