Hydraulic Press C

Hydraulic press C incorporates expertise gained from decades of hands-on experience. Unique to this press is the technique with which bricks are laid into three rows of die cavities, which means a total of 48 standard bricks can be made for each pressing cycle.

Special bricks can be made with this press. They include hollow bricks, permeable bricks, and bricks with blind holes. When employed to make blocks, the press produces 8 pieces with 390mm×190 mm×190mm in dimension and with porosity up to 52% per pressing cycle. As well as traditional sands and stone powder, pulverized fuel ash, FGD gypsum, phosphogypsum, and other industrial solid wastes also can be used to produce bricks.

In addition, a number of servo proportional valves are employed to provide precise control of piston position and ensure a proper level of pressure that is applied to the brick.

Features

1. The hydraulic press employs advanced separate cross beams and the demoulding oil cylinder characterized by good rigidity and extended lifespan.

2. For high productivity, the press adopts prefill valve with large diameter. The hydraulic system is equipped with high-flow pump with constant power, and oil system with high capacity accumulator. In addition, the hydraulic press utilizes proportional pressure control technology to realize flexible pressurization.

3. The press uses proportional control technology to regulate crossbeam lifting, frame sliding, and charger, resulting in smooth operation and precision positioning. For example, the closed loop control technology helps realize the positioning error of the charger less than 2mm, thus greatly reducing the damage to the brick caused by the stacker of the hydraulic press.

4. The counterweight system of the material feeder is designed in hammer-type structure for smooth movement of the sliding frame and the precise positioning of the guide post.

5. Controlled by servo motor, the gripper of the brick stacker is distinguished by precise positioning, accurate brick release, and smooth and rapid operation.

6. The critical parts, such as the main cylinder, demoulding cylinder seal, proportional valve, and the electric element, are purchased from the internationally famous brands.

7. Luckily, this hydraulic press can be customized based on customer demand. For instant, the supercharging demoulding valve can be installed to enlarge demoulding force, and customers can choose the solid block manufacturing equipment engineered with regular stacker, or stacker robot.

Specification

| Nominal Pressure(KN) | 13,000 |

| Demoulding Force(KN) | 2,000 |

| Maximum Stroke (mm) | 680 |

| Shut Height (mm) | 1,600 |

| Number of Standard Bricks Per Cycle | 48 |

| Main Motor Power (kW) | 110 |

Related Names

Baking Free Brick Maker | Cement Brick Making Machine | Solid Block Manufacturing Equipment

Links:https://www.globefindpro.com/products/81793.html

-

Clamping Machine

Clamping Machine

-

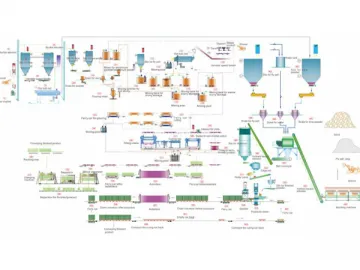

AAC Block & Sand-lime Brick Production Line

AAC Block & Sand-lime Brick Production Line

-

Machine for Steel Pin Drawing

Machine for Steel Pin Drawing

-

60cm Ku Band Satellite Dish

60cm Ku Band Satellite Dish

-

Machine for Frame Seat Cycling

Machine for Frame Seat Cycling

-

120cm Ku Band Satellite Dish

120cm Ku Band Satellite Dish

-

Carbon Steel Pipe (ERW,SSAW,API 5L)

Carbon Steel Pipe (ERW,SSAW,API 5L)

-

Aluminized Steel Sheet (ALCOT)

Aluminized Steel Sheet (ALCOT)

-

Steel Coil Mini Shearing

Steel Coil Mini Shearing

-

100cm C Band Satellite Dish

100cm C Band Satellite Dish

-

150cm Ku Band Satellite Dish

150cm Ku Band Satellite Dish

-

85cm Ku Band Satellite Dish

85cm Ku Band Satellite Dish