This range of conveyor chain is manufactured for metallurgy industry, for instance, in steel mills. To meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

Our conveyor chain supports conveying of steel coils and steel sheets as well as steel rollers. In addition, we can offer metallurgy industry-use chains for material cooling and drying, steel ingot lifting, steel pipe pushing and drawing, as well as more purposes.

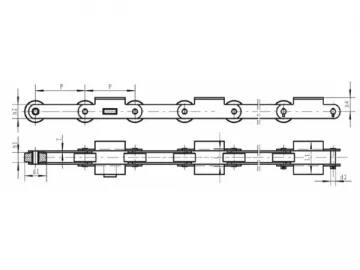

Conveyor Chain for Steel Sheets| Chain no. | Pitch P1 (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin L (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Width of attached plate L1 (mm) | Tensile strength Q (KN) |

| YB250 | 250 | 50 | 110 | 25 | 90 | 8 | 70 | 165 | 300 |

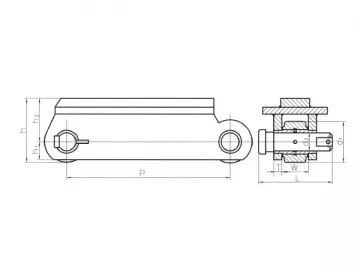

Lifting Chain for Steel Ingots | Chain no. | Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin L (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Width of attached plate L1 (mm) | Tensile strength Q (KN) |

| TS250 | 250 | 57 | 120 | 30 | 128 | 85 | 12 | 302 | 450 |

Steel Pipe Pushing / Drawing Chain | Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin L (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Width of attached plate H2 (mm) | Tensile strength Q (KN) |

| 160 | 40 | 76 | 20 | 100 | 50 | 10 | 180 | 171.5 |

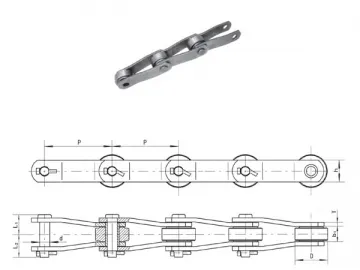

Conveyor Chain for Steel Coils | Chain no. | Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Diameter of outer roller d5 (mm) | Tensile strength Q (KN) |

| 500-A | 500 | 76 | 160 | 44 | 140 | 20 | 90 | 1300 |

| Chain no. | Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Diameter of outer roller d5 (mm) | Tensile strength Q (KN) |

| 500-B | 500 | 80 | 160 | 44 | 140 | 20 | 90 | 1300 |

Cold Bed Chain| Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of top chain H2 (mm) | Tensile strength Q (KN) |

| 135 | 45 | 50 | 30 | 103.5 | 90 | 12 | 120 | 500 |

| Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of top chain H2 (mm) | Tensile strength Q (KN) |

| 135 | 45 | 50 | 25 | 100 | 80 | 8 | 150 | 320 |

| Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of top chain H2 (mm) | Tensile strength Q (KN) |

| 250 | 38 | 50 | 25 | 160 | 70 | 10 | 140 | 320 |

| Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of top chain H2 (mm) | Tensile strength Q (KN) |

| 220 | 37 | 36 | 19.05 | 146 | 50 | 8 | 125 | 200 |

| Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of top chain H2 (mm) | Tensile strength Q (KN) |

| 125 | 40 | 56 | 30 | 176 | 70 | 10 | 120 | 315 |

| Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of top chain H2 (mm) | Tensile strength Q (KN) |

| 100 | 40 | 46 | 20 | 148 | 60 | 8 | 80 | 175 |

Conveyor Chain for Rollers | Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of top chain H2 (mm) | Tensile strength Q (KN) |

| 125 | 68.5 | 25 | 60 | 262 | 70 | 18 | 141.3 | 320 |

| Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin L (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of top plate H2 (mm) | Tensile strength Q (KN) |

| 100 | 40 | 46 | 20 | 165 | 60 | 8 | 98 | 175 |

Air Drying Chain | Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin L (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of top plate H2 (mm) | Tensile strength Q (KN) |

| 80 | 72 | 40 | 20 | 131 | 70 | 10 | 110 | 360 |

| Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin L (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of top plate H2 (mm) | Tensile strength Q (KN) |

| 80 | 72 | 40 | 20 | 131 | 70 | 10 | 110 | 360 |

Conveyor Chain (for Assisting Painting Work)| Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin L (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Tensile strength Q (KN) |

| 101.6 | 38 | 48.5 | 15.88 | 88.7 | 50.8 | 9.5 | 220 |

| Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin L (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of attached plate H2 (mm) | Tensile strength Q (KN) |

| 101.6 | 38 | 48.5 | 15.88 | 88.7 | 38.1 | 9.5 | 104 | 220 |

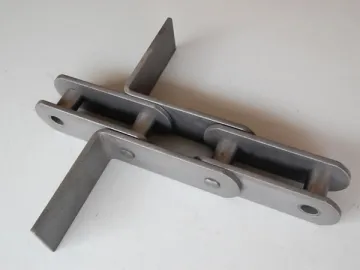

Push Conveyor Chain (with Attachment for Material Pushing Purpose) | Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin L (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of attached plate H2 (mm) | Tensile strength Q (KN) |

| 150 | 42 | 80 | 40 | 110 | 80 | 40 | 10 | 600 |

Cart Pushing and Drawing Chain| Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin L (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of attached plate H2 (mm) | Tensile strength Q (KN) |

| 100 | 37 | 36 | 16 | 68.5 | 40 | 6 | 132 | 160 |

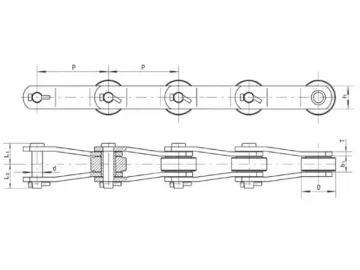

Loading Chain for Metallurgical Use (Type 1)| Chain No. | Roller type | Pitch P (mm) | Inner width of inner link W (mm) | Diameter of roller R (max) (mm) | Height of chain H (mm) | Data of sidebar | Data of pin | Tensile strength Q (KN) |

| H1 (mm) | H2 (mm) | T (mm) | B (mm) | L1 (mm) | L2 (mm) | D (mm) |

| W03075 | R | 75 | 16.1 | 31.8 | 36.9 | 21 | 4.9 | 3.2 | 50 | 18 | 20 | 7.92 | 30 |

| W03100 | R | 100 | 16.1 | 31.8 | 36.9 | 21 | 4.9 | 3.2 | 50 | 18 | 20 | 7.92 | 30 |

| W07100 | R | 100 | 22 | 40 | 44 | 24 | 4 | 4.5 | 68 | 24.5 | 29 | 11.1 | 70 |

| W07150 | R | 150 | 22 | 40 | 44 | 24 | 4 | 4.5 | 68 | 24.5 | 29 | 11.1 | 70 |

| W08150 | R | 150 | 27 | 44.5 | 50.3 | 28 | 8 | 6.3 | 80 | 31 | 35 | 11.1 | 80 |

| W11150 | R | 150 | 30 | 50.8 | 57.4 | 32 | 6.4 | 6.3 | 90 | 33.5 | 40 | 14.27 | 115 |

| W11100 | R | 100 | 30 | 50.8 | 57.4 | 32 | 6.4 | 6.3 | 90 | 33.5 | 40 | 14.27 | 115 |

| W19152 | R | 152.4 | 37.1 | 57.2 | 63.5 | 35 | 6 | 8 | 105 | 41.5 | 47.5 | 15.9 | 190 |

| W19200 | R | 200 | 37.1 | 65 | 73.5 | 41 | 10 | 8 | 105 | 41.5 | 47.5 | 15.9 | 190 |

| W19250 | R | 250 | 37.1 | 65 | 73.5 | 41 | 10 | 8 | 105 | 41.5 | 47.5 | 15.9 | 190 |

| W25250 | R | 250 | 51.4 | 80 | 90 | 50 | 13.8 | 10 | 122 | 52 | 54.5 | 19.1 | 250 |

| W25300 | R | 300 | 51.4 | 80 | 90 | 50 | 13.8 | 10 | 122 | 52 | 54.5 | 19.1 | 250 |

| W28200 | R | 200 | 49 | 85 | 95.5 | 53 | 10.5 | 10 | 145 | 52 | 61 | 22.2 | 285 |

| W28300 | R | 300 | 57.2 | 85 | 95.5 | 53 | 10.5 | 10 | 145 | 56 | 65 | 22.2 | 285 |

| W48250 | R | 250 | 66.7 | 110 | 112 | 62 | 12 | 12.7 | 170 | 68 | 77 | 25.4 | 485 |

| W48300 | R | 300 | 66.7 | 100 | 112 | 62 | 12 | 12.7 | 170 | 68 | 77 | 25.4 | 485 |

| W48400 | R | 400 | 66.7 | 100 | 112 | 62 | 12 | 12.7 | 170 | 68 | 77 | 25.4 | 485 |

| W51450 | R | 450 | 77 | 110 | 125 | 70 | 17 | 16 | 200 | 82.5 | 93 | 31.8 | 510 |

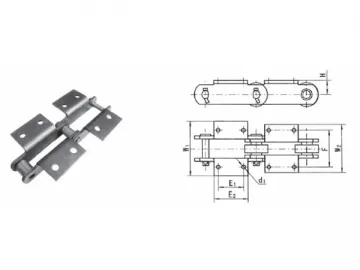

Loading Chain for Metallurgical Use (Type 2)| Chain No. | Pitch P (mm) | Roller | Inner width W (mm) | Sidebar | Pin | S (mm) | Top roller | b (mm) | b1 (mm) | Allowable working load of top roller | Tensile strength (KN) | A type weight (kg/m) | B type weight (kg/m) | Attachment weight (kg) |

| Diameter R (mm) | Roller width E (mm) | Height H (mm) | Thickness T (mm) | d (mm) | L1 (mm) | L2 (mm) | Diameter R1 (mm) | Top roller width E1 (mm) | Not heat-treated | Heat treated |

| WTR03075 | 75 | 31.8 | 14 | 16.1 | 22 | 3.2 | 7.92 | 18 | 20 | 23.1 | 40 | PL:20 RL:14 | 59 | 50 | 35 | 60 | 30 | 4.1 | 4.3 | 0.2 |

| WTR03100 | 100 | 31.8 | 14 | 16.1 | 22 | 3.2 | 7.92 | 18 | 20 | 23.1 | 40 | PL:20 RL:14 | 59 | 50 | 35 | 60 | 30 | 3.3 | 3.5 | 0.2 |

| WTR07100 | 100 | 40 | 19 | 22 | 32 | 4.5 | 11.1 | 25 | 28.5 | 30 | 40 | PL:28 RL:19 | 70 | 67 | 65 | 105 | 70 | 6.4 | 6.8 | 0.28 |

| WTR07150 | 150 | 40 | 19 | 22 | 32 | 4.5 | 11.1 | 25 | 28.5 | 30 | 40 | PL:28 RL:19 | 70 | 67 | 65 | 105 | 70 | 5 | 5.4 | 0.28 |

| WTR08150 | 150 | 44.5 | 23 | 27 | 8.6 | 6.3 | 11.1 | 31 | 34.5 | 30 | 40 | PL:35 RL:23 | 72.2 | 79 | 80 | 130 | 80 | 6.3 | 6.8 | 0.38 |

| WTR11150 | 150 | 50.8 | 26 | 30 | 38.1 | 6.3 | 14.27 | 33 | 36 | 30 | 50.8 | PL:38 RL:26 | 80.8 | 82 | 115 | 195 | 115 | 9.9 | 10.5 | 0.6 |

| WTR19150 | 152.4 | 57.2 | 32 | 37.1 | 44.5 | 8 | 15.9 | 40.5 | 43 | 37.8 | 57.2 | PL:48 RL:32 | 95 | 96 | 150 | 255 | 190 | 15.5 | 16.2 | 0.96 |

| WTR19200 | 200 | 65 | 32 | 37.1 | 44.5 | 8 | 15.9 | 40.5 | 43 | 45 | 65 | PL:48 RL:32 | 110 | 96 | 150 | 255 | 190 | 14.6 | 15.4 | 1.22 |

| WTR25200 | 200 | 80 | 44 | 51.4 | 50.8 | 10 | 19.1 | 51.5 | 58 | 65 | 80 | PL:64 RL:44 | 145 | 126 | 250 | 420 | 250 | 26 | 27 | 2.66 |

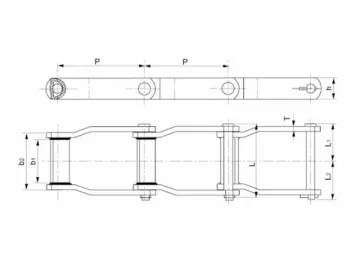

Cast Steel Chain | Chain No. | Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Height of sidebar h2 (mm) | Thickness of sidebar T (mm) | Height of platform H2 (mm) | Tensile strength Q (KN) |

| ZG700 | 700 | 46 | 80 | 50 | 140 | 38 | 70 | 1300 |

Related Names

Cranked Link Chain | Steel Mill Chain | Slat Conveyor Chain

Heavy Duty Extended Pitch Roller Chain

Heavy Duty Extended Pitch Roller Chain

Offset Link Chain for Sugar Industry

Offset Link Chain for Sugar Industry

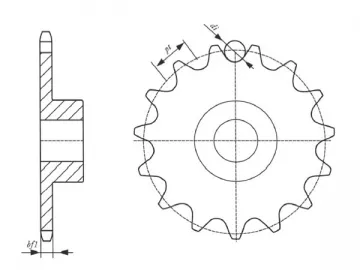

Double Pitch Precision Roller Chain Sprocket

Double Pitch Precision Roller Chain Sprocket

Offset Link Chain for Palm Oil Industry

Offset Link Chain for Palm Oil Industry

Scraper Conveyor Chain Sprocket

Scraper Conveyor Chain Sprocket

Chain Attachments for Palm Oil Industry

Chain Attachments for Palm Oil Industry

Heavy Duty Offset Link Roller Chain Sprocket

Heavy Duty Offset Link Roller Chain Sprocket

Conveyor Chain for Grain Machines

Conveyor Chain for Grain Machines

Elevator Chain

Elevator Chain

Wide Series Welded Steel Chain

Wide Series Welded Steel Chain

35cm Ku Band Satellite Dish

35cm Ku Band Satellite Dish

Hydraulic Press B

Hydraulic Press B