Trencher Chain

Aside from the trencher chain, we also offer similar roller chains to suit the application demands of many other types of engineering machinery.

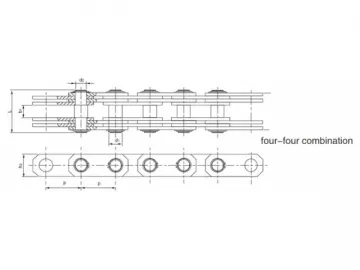

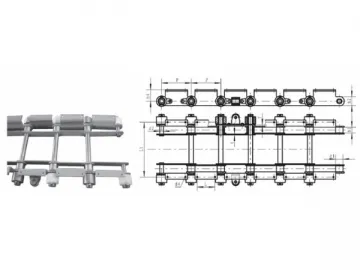

This series of transmission chain for trenchers is mainly used in dirty environment, and has high requirement on its performance in withstanding impact load. For optimized performance, we design this product based on simulated working environment. Also, we give special attentions to the design of each chain component so as to meet application demands perfectly. The design details are given below.

1. The product is designed with increased gap between the bushing and the pin, as well as the gap between the roller and the bushing. Thus, the flexible turning and rotation movements are ensured.

2. Due to the optimized clearance between the sidebar and the pin, as well as the clearance between the sidebar and the bushing, the connection firmness between the sidebars and the pin/bushing is largely enhanced.

3. The bushing with increased carburized depth helps extend the service life of the trencher chain.

4. Some wearing parts are hard chromium plated to avoid too quick surface abrasion.

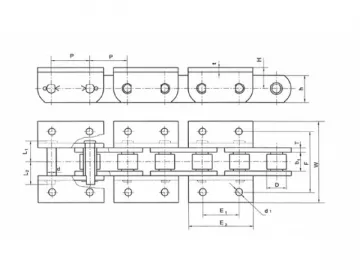

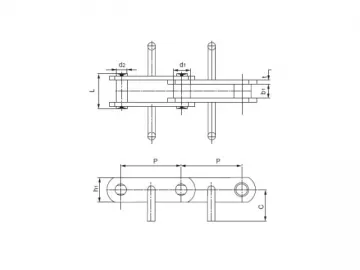

| Chain no. | Pitch P(mm) | Width of inner link b1(mm) | Sidebar | Pin | Diameter of roller d1(mm) | Tensile strength Q(min)(KN) | Weight per meter q kg/m | ||||

| T mm | h mm | H mm | d1 mm | L1 mm | L2 mm | ||||||

| 2250GL-M | 42.01 | 25.2 | 4.9 | 31.8 | 38.1 | 11.1 | 26.9 | 29.4 | 22.23 | 120 | 6.57 |

| 2250GL-M2 | 42.01 | 25.5 | 6.4 | 31.8 | 60.3 | 11.1 | 26.9 | 33.9 | 22.23 | 120 | 6.47 |

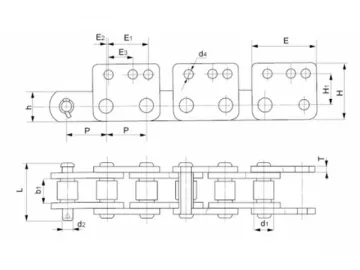

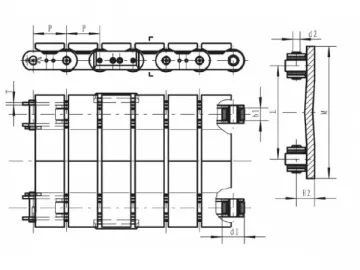

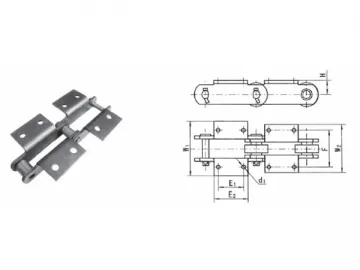

| Chain no. | Pitch P(mm) | Width of inner link b1(mm) | Sidebar | Pin | Diameter of roller d1(mm) | Tensile strength Q(min)(KN) | Weight per meter q kg/m | |||||||||

| T mm | h mm | H1 mm | H mm | E mm | E1 mm | E2 mm | E3 mm | d4 mm | d2 mm | L mm | ||||||

| 2250GL-M3 | 42.01 | 25.2 | 4.9 | 31.8 | 33.3 | 60.3 | 69.8 | 41.3 | 2.9 | 25.4 | 9.95 | 11.1 | 56.3 | 22.23 | 120 | 7.78 |

Related Names

Trench Digger Chain | Trenching Machine Chain | Steel Pintle Chain

Links:https://www.globefindpro.com/products/81842.html

-

Conveyor Chain for Paper Roll

Conveyor Chain for Paper Roll

-

Other Chain for Sugar Industry

Other Chain for Sugar Industry

-

Straight Side Plate Chain for Sugar Industry

Straight Side Plate Chain for Sugar Industry

-

Forged Caterpillar Drive Chain

Forged Caterpillar Drive Chain

-

Steel Draw Bench Chain

Steel Draw Bench Chain

-

Forged Scraper Chain

Forged Scraper Chain

-

Conveyor Chain for Automobile Industry

Conveyor Chain for Automobile Industry

-

Heavy Duty Offset Sidebar Roller Chain

Heavy Duty Offset Sidebar Roller Chain

-

DF3500 and DF3498 Type Offset Link Chain

DF3500 and DF3498 Type Offset Link Chain

-

Forged Drive Chain

Forged Drive Chain

-

FU Style Conveyor Chain

FU Style Conveyor Chain

-

Chain Attachments for Palm Oil Industry

Chain Attachments for Palm Oil Industry