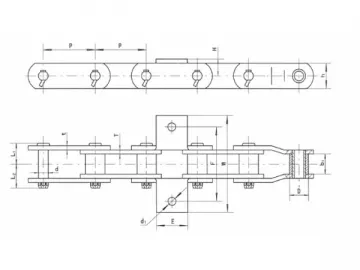

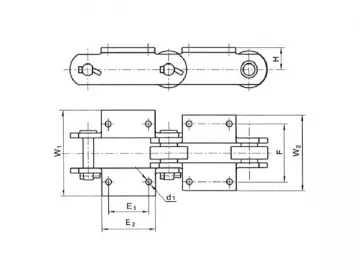

Forged Chain Attachments

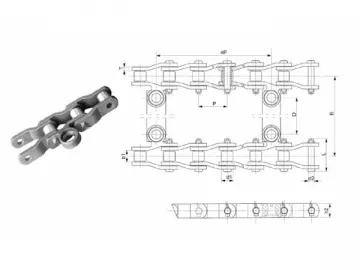

This page introduces you our forged chain attachments, including the hanger bracket, outer link plate, carrier for goods carrying, as well as the forged detachable chain assembly. These attachments can be combined together selectively for use in specific applications. For instance, the forged hanger bracket, carrier, and outer link plate are usually combined used in overhead trolley conveyors.

The Construction of Overhead Trolley Conveyor

1. Forged Hanger Bracket

This forged chain attachment functions to support the weight of materials or goods, the carrier, and the drive chain. Its bottom part also needs to bear the tension force from the tensioned chains. Additionally, the hanger bracket is responsible for making sure the drive chain moves along the overhead track.

In an overhead trolley conveyor system, when the distance between two loaded hanger brackets exceeds 800-900mm, an unloaded bracket can be mounted between them so as to increase system strength.

We can offer forged brackets of X348, X458, X678, CC100, and X160 series.

| Forged hanger bracket model | Dimensions | Weight (kg/set) | ||||||

| A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | F(mm) | G(mm) | ||

| X348 | 64 | 60 | 100 | 100 | 25.5 | 22.5 | 16 | 1.35 |

| X458 | 82 | 80 | 136 | 128.6 | 33.5 | 20.5 | 20 | 2.7 |

| X678 | 89 | 82 | 144 | 136 | 31 | 23 | 16 | 3.45 |

| CC100 | 82 | 82 | 136 | 128.6 | 25.5 | 22.5 | 18 | 2.7 |

| X160 | 101.6 | 120 | 170 | 170 | 42 | 28 | 20 | 7.5 |

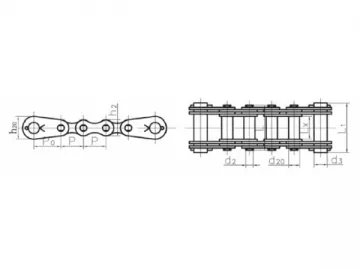

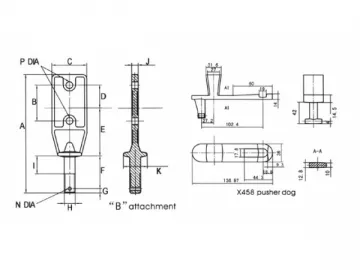

2. Carrier & Push Rod (Pusher Dog)

| Model | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) | I (mm) | J (mm) | K (mm) | L (mm) | N (mm) | P (mm) | Wt (kg) |

| 348 | 146 | 48 | 38.1 | 26 | 62 | 40 | 6 | 12 | 15 | 6.4 | 32 | M12 | 4 | 9 | 0.22 |

| 458 | 178 | 54 | 50 | 33.5 | 71.5 | 52 | 6 | 16 | 32 | 9.5 | 35 | M16 | 4 | 10.5 | 0.45 |

| 678 | 222 | 70 | 76 | 41.5 | 79 | 67 | 9.5 | 22 | 41.2 | 12.7 | 51 | M22 | 5.5 | 10.5 | 1.27 |

Related Names

Forged Chain Assembly | Metal Lifting Components | Detachable Chain Parts

Links:https://www.globefindpro.com/products/81858.html