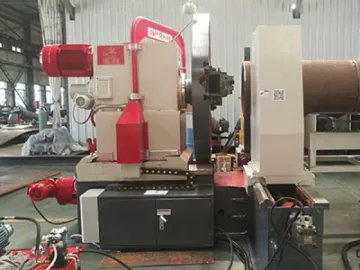

High Speed Pipe Cutting and Beveling Machine

Model: DPCBM-16Aa/24Aa

Technical Parameters Pipe Diameter Applicable: DN400/DN600 Pipe Wall Thickness Applicable: 3~12MM Applicable Materials: Carbon steel, alloy steel, stainless steel and cryogenic steel Bevel Shape: V Structure: A four column suspending structure is used. Since it is hollow, the pipe can go into the machine directly and is fixed there. The cutter rotates and cuts the pipe circumferentially with high speed. Cutting Direction: Lengthwise Driven by: Motor Clamping System: Clamped by cylinder Control System: PLC VF control and Touching Screen with man-machine interface Length-Measuring System: A mechanical length-measuring system can be provided if necessary to measure the length of the pipes as well as cut and bevel them with the supporting of the conveying system of the cutting and beveling machine. Mechanical Aligning: An automatic lifting and lowering device is equipped to automatically adjust the center elevation of the beveling machine, so pipes with different diameters get the same bottom elevation on the production line to get the pipes in/out of the machine easily. Conveying System: Cutting and beveling conveying systems are equipped at front and rear sides of the beveling machine if necessaryApplications

The high speed pipe cutting and beveling machine is used for cutting large amounts of pipes with standard wall thickness or thin wall thickness and beveling the V-shape bevel.

The high speed pipe cutting and beveling machine offers a beveling capacity of ≤5Min /two pipe bevels (DN200 SCH40). It offers bevel cutting of: cutting off pipe and two bevels simultaneously. The bevel quality of the high speed pipe cutting and beveling machine is good. There is no need for cutting surplus so the material can be saved. The high speed pipe cutting and beveling machine has low mobility. Synchronously centering clamping with cam clamping mechanism drived by the front and back hydraulic cylinders; cutting and beveling blade disc rotates at high speed around the pipe center; when generate speed difference from 2 cutter disc of internal and external that are respectively drive by 2 servo motors, the cutting feed gear drive mechanism began to motion, to drive automatic radial feed for cutting tools and beveling tools; equipped with spray cooling device; preset bevel parameters through PLC touch screen human-machine interface; four-column & four linear guide rail & two lifts to compose lifting system enabling automatically mechanical centering; cutting and beveling in one operation (simultaneously producing two bevels); extremely high beveling efficiency; applicable for large amount of STD wall thickness (≤25mm) pipe bevel machining.

Scan QR to Read

Links:https://www.globefindpro.com/products/8187.html

Links:https://www.globefindpro.com/products/8187.html

Recommended Products

-

Axial Pipe End Beveling Machine

Axial Pipe End Beveling Machine

-

Automatic Welding Machine for Pipe Spool Root Pass Weld (GMAW/GTAW/FCAW)

Automatic Welding Machine for Pipe Spool Root Pass Weld (GMAW/GTAW/FCAW)

-

Calendar Rims

Calendar Rims

-

Magnetic Pipe Flame Cutting and Beveling Machine

Magnetic Pipe Flame Cutting and Beveling Machine

-

High Speed Pipe and Fittings Bevelling Machine

High Speed Pipe and Fittings Bevelling Machine

-

Pipe Fabrication Production Line (Transportable Type)

Pipe Fabrication Production Line (Transportable Type)

-

Automatic Piping Welding Machine (SAW, Cantilever)

Automatic Piping Welding Machine (SAW, Cantilever)

-

Clipboard Clips

Clipboard Clips

-

HMF LED High Mast Light

HMF LED High Mast Light

-

Curtain Rod Rings

Curtain Rod Rings

-

Automatic Piping Welding Machine (GTAW, Cantilever)

Automatic Piping Welding Machine (GTAW, Cantilever)

-

Lever Arch Mechanism

Lever Arch Mechanism

Hot Products