YH10W, YH5W Series Polymer Lightning Arrester

Since the porcelain housed lightning arrestor is large and heavy, causing it inconvenient and costly to transport, our company launched the polymer lightning arrester at the end of 1991. Small, light, collision-resistant, as well as easy to install and maintain, our product meets the technical requirements of GB11032-2000, IEC60099-4, and IEEE.C62.11. It is an ideal choice for lightning protection.

Mounting Plate

The housing of our polymer lightning arrester is formed by overall silicone rubber compression molding. It has excellent sealing and explosion-proof properties. It is resistant to aging, electrical erosion, as well as contamination and free from cleaning. Also, the possibility of wet flashover in foggy days is reduced.

The silicone rubber used in this device is produced by our company. Due to the production technology modified on the basis of the technology introduced from Hitachi, the silicone rubber we produce is capable of resisting aging for over 5,000 hours. It was verified by the Beijing Electric Power Research Institute at the end of 2010. This technology breakthrough, which greatly extends the life of the lightning arrester, is currently hard to achieve for our domestic competitors.

Our product is equipped with brand new varistor rather than refurbished ones, thus enjoying outstanding nonlinear IV characteristics, steep wave response, improved overvoltage flow capacity, reduced discharge dispersion, and small impact factor.

The product core rod is wound by the weftless binding tape. The assembly is then heated for 6 hours in energy-saving hot air circulation oven to make the weftless binding tape cure, thus better protecting the varistor and aluminum poles. Meanwhile, an electric strapping machine is adopted, ensuring no gap between the varistor and aluminum pole, which effectively prevents the glue in the weftless binding tape from permeating.

In addition, our lightning arrester is produced in the cleanroom by technicians with 7 or 8 years of production experience, which ensure the quality of the finished product to a certain degree.

Technical Parameters of Polymer Lightning Arrester

| Model | Rated voltage | Maximum continuous operating voltage | Max. residual voltage | 2000μs square-wave current impulse withstand current | 4/10μs high current impulse | ||

| Steep current impulse | 30/60 μs switching current impulse | 8/20 μs lightning current impulse | |||||

| kV (RMS) | kV (RMS) | kV (peak) | kV (peak) | kV (peak) | A (peak) | kA (peak) | |

| YH5W-3 | 3 | 2.55 | 10.0 | 8.3 | 9 | 100 | 65 |

| YH5W-6 | 6 | 5.1 | 20.0 | 16.4 | 18 | 100 | 65 |

| YH5W-9 | 9 | 7.65 | 31.0 | 23.8 | 27 | 100 | 65 |

| YH5W-10 | 10 | 8. 3 | 36.0 | 27.0 | 30 | 100 | 65 |

| YH5W-11 | 11 | 9. 5 | 38.5 | 30.0 | 33 | 100 | 65 |

| YH5W-12 | 12 | 10.2 | 38.0 | 30.8 | 36 | 100 | 65 |

| YH5W-15 | 15 | 12.7 | 52.0 | 38.5 | 45 | 100 | 65 |

| YH5W-18 | 18 | 15.3 | 61.4 | 46.2 | 54 | 100 | 65 |

| YH5W-21 | 21 | 17.0 | 70.8 | 54.2 | 63 | 100 | 65 |

| YH5W-24 | 24 | 19.5 | 76.0 | 62.0 | 72 | 100 | 65 |

| YH5W-27 | 27 | 22.0 | 92.5 | 71.6 | 81 | 100 | 65 |

| YH5W-30 | 30 | 24.4 | 102.0 | 79.5 | 90 | 100 | 65 |

| YH5W-33 | 33 | 26.8 | 110.0 | 89.0 | 99 | 100 | 65 |

| YH5W-36 | 36 | 29.0 | 123.5 | 96.0 | 108 | 100 | 65 |

| YH5W-42 | 42 | 34.1 | 132.3 | 100.1 | 126 | 100 | 65 |

| Model | Rated voltage | Maximum continuous operating voltage | Max. residual voltage | 2000μs square-wave current impulse withstand current | 4/10μs high current impulse | ||

| Steep current impulse | 30/60 μs switching current impulse | 8/20 μs lightning current impulse | |||||

| kV (RMS) | kV (RMS) | kV (peak) | kV (peak) | kV (peak) | A (peak) | kA (peak) | |

| YH10W-3 | 3 | 2.55 | 10.0 | 8.3 | 9 | 250 | 100 |

| YH10W-6 | 6 | 5.1 | 20.0 | 16.4 | 18 | 250 | 100 |

| YH10W-9 | 9 | 7.65 | 31.0 | 23.8 | 27 | 250 | 100 |

| YH10W-10 | 10 | 8. 3 | 36.0 | 27.0 | 30 | 250 | 100 |

| YH10W-11 | 11 | 9. 5 | 38.5 | 30.0 | 33 | 250 | 100 |

| YH10W-12 | 12 | 10.2 | 41.0 | 30.8 | 36 | 250 | 100 |

| YH10W-15 | 15 | 12.7 | 52.0 | 38.5 | 45 | 250 | 100 |

| YH10W-18 | 18 | 15.3 | 61.4 | 46.2 | 54 | 250 | 100 |

| YH10W-21 | 21 | 17.0 | 70.0 | 54.2 | 63 | 250 | 100 |

| YH10W-24 | 24 | 19.5 | 82.5 | 62.0 | 72 | 250 | 100 |

| YH10W-27 | 27 | 22.0 | 92.5 | 71.6 | 81 | 250 | 100 |

| YH10W-30 | 30 | 24.4 | 102.0 | 79.5 | 90 | 250 | 100 |

| YH10W-33 | 33 | 26.8 | 110.0 | 89.0 | 99 | 250 | 100 |

| YH10W-36 | 36 | 29.0 | 123.5 | 96.0 | 108 | 250 | 100 |

| YH10W-42 | 42 | 34.0 | 140.0 | 112.0 | 126 | 250 | 100 |

| YH10W-48 | 48 | 39.0 | 152.0 | 126.0 | 150 | 400 | 100 |

| YH10W-54 | 54 | 43.0 | 171.0 | 139.0 | 162 | 400 | 100 |

| YH10W-60 | 60 | 48.0 | 208.0 | 160.0 | 180 | 400 | 100 |

| YH10W-66 | 66 | 53.4 | 230.0 | 172.0 | 198 | 400 | 100 |

Note:

1. The "YH" in the model means the lightning arrester has a polymer housing.

2. The above product models are for reference. We can design and make products according to the requirements of the customers or according to the drawings provided by them.

Related Names

Lightning Surge Protection Device | High Voltage Surge Arrester | Building Lightning Protector

Links:https://www.globefindpro.com/products/81893.html

-

Pest Control Toolbox

Pest Control Toolbox

-

RY1-B Series Surge Protection Device (SPD)

RY1-B Series Surge Protection Device (SPD)

-

Solar Bug Zapper (Box Style)

Solar Bug Zapper (Box Style)

-

Standard Moth Traps

Standard Moth Traps

-

Fuse Cutout Accessories

Fuse Cutout Accessories

-

Solar Bug Zapper (Post Style)

Solar Bug Zapper (Post Style)

-

Surge Counter

Surge Counter

-

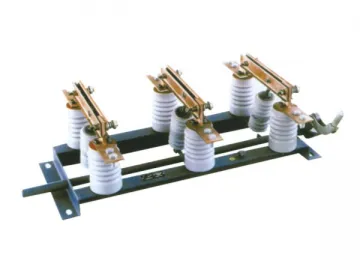

Indoor High Voltage AC Disconnector

Indoor High Voltage AC Disconnector

-

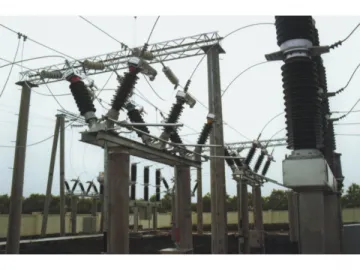

(H)GW5 Outdoor High Voltage AC Disconnector

(H)GW5 Outdoor High Voltage AC Disconnector

-

Arrester Disconnector

Arrester Disconnector

-

Micro Imaging System

Micro Imaging System

-

PAR30 LED Lamp

PAR30 LED Lamp