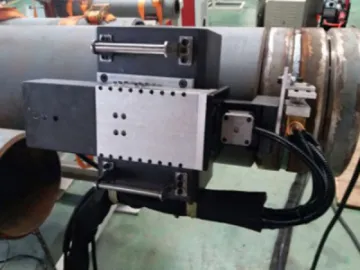

Pipe Fabrication Fast Fitting Up Machine

Model: PFFUM-16Aa/24Aa/32Aa/48Aa/64Aa;PFFUC-16Aa/24Aa/32Aa/48Aa/64Aa

Technical Parameters Pipe Diameter Applicable: DN400/DN600/DN800/DN1200/DN1600 The Longest Pipe: 6M (or depending on the situation) Fitting-up System: 1 set; 2 sets Moving Up/Down: With screw lifter, driven electrically Moving Left/Right: Linear guiding rail, driven and movement electrically Vertical Turnover: With screw lifter, driven electrically Lengthwise Moving: Motorized driving square-steel track Max Loading Capability: 500KG/500KG/1000KG/1000KG; 750KG/750KG/1500KG/1500KG Bracket System: 2 sets Max Loading Capability: 2,500KG Lengthwise Moving: Manually driving Track System: 1 set Track Length: 7.5M (or depending on the situation) Track Type: Square-steel trackApplications

The piping fabrication fast fitting-up machine is used for standard wall thickness pipes and fittings (A1/A2) and heavy wall thickness pipe and fittings (A3/A4).

The piping fabrication fast fitting-up machine offers fit-up and tack welding of the straight pipe with fittings such as flange elbow, tee, etc. directly. The machine increases the efficiency and quality of pipe-fittings such as flange elbow, tee, etc. fitting-up. The piping fabrication fast fitting-up machine requires fewer skills for fitting-up pipes and flanges and reduces work difficulty for the operators. Patented product, the first commercialized multi-functional fitting-up machine; realizing multi-functional fitting-up pipe and pipe fittings such as flange, elbow, tee, reducer, etc; realizing electrically-powered moving in six directions up/down, left/right, front/back; with double supporting travelling trolleys; operated by aluminum alloy control box. The most efficient machine widely used domestically and overseas. Patented product; suitable for fitting up segments with “fitting pipe fitting”; fitting-up efficiency increased by more than 100%; two multi-functional fitting-up heads; two movable supporting trolleys; one machining rail; fitting-up heads installed separately at both ends of the rail and travel along the centerline in the axial direction according to the length of pipe; fitting up synchronously at both ends (fitting-up heads move in six directions automatically: up/down/left/right /back/front); operated with aluminum alloy control box.

Scan QR to Read

Links:https://www.globefindpro.com/products/8197.html

Links:https://www.globefindpro.com/products/8197.html

Recommended Products

-

Automatic Magnetic Pulse Pipeline Welding Machine

Automatic Magnetic Pulse Pipeline Welding Machine

-

Pipe Fabrication Production Line (Fixed Type)

Pipe Fabrication Production Line (Fixed Type)

-

PDSOFT Piping Process Management Software

PDSOFT Piping Process Management Software

-

Automatic Pipe Welding Machine (MIG)

Automatic Pipe Welding Machine (MIG)

-

Automatic Pipe Welding Machine (FCAW/GMAW)

Automatic Pipe Welding Machine (FCAW/GMAW)

-

Pipe Flame Beveling and Cutting Machine (Roller Bench Type)

Pipe Flame Beveling and Cutting Machine (Roller Bench Type)

-

Automatic Pulse Tube Sheet Welding Machine (GTAW/TIG)

Automatic Pulse Tube Sheet Welding Machine (GTAW/TIG)

-

PDSOFT Piping Prefabrication Detail Design Software

PDSOFT Piping Prefabrication Detail Design Software

-

Multifunction Automatic Pipe Welding Machine (TIG MIG SAW, Press Roller Type)

Multifunction Automatic Pipe Welding Machine (TIG MIG SAW, Press Roller Type)

-

Pipe Fabrication Production Line (Transportable Type)

Pipe Fabrication Production Line (Transportable Type)

-

High Speed Pipe and Fittings Bevelling Machine

High Speed Pipe and Fittings Bevelling Machine

-

Magnetic Pipe Flame Cutting and Beveling Machine

Magnetic Pipe Flame Cutting and Beveling Machine