GYWT Type Roof Ventilator

Generation Introduction

The GYWT type roof ventilator is mainly engineered from profiled color plates or glass fiber reinforced plastics. It is developed on the basis of Australian and Italian technologies, and combines the characteristics of domestics and overseas like products.

Features of the GYWT Type Roof Ventilator

1. Our range of roof ventilator has undergone multiple work condition optimal experiments on air distribution and been improved repeatedly in structure. Its structure has been changed from angular to streamline, which greatly enhances its performance.

2. With small air exhaust resistance and smooth air motion, the rooftop natural ventilation system is capable of withstanding air pressure.

3. Compared with a skylight, the roof ventilator enjoys 30% higher air exhaust efficiency owing to its discharge coefficient of 0.8-0.85.

4. The roof ventilation system can effectively protect against rain, snow and wind. The power-driven valve plate can be flexibly opened in summer for ventilation and tightly closed in winter for heat preservation.

5. If the roof ventilator is to be used in industrial plants with high humidity, its valve plate and backplate can be thermal insulated to avoid moisture condensation.

Applications of the GYWT Type Roof Ventilator

With reasonable structure, superior performance and simple appearance, this rooftop ventilator is ideal for workshops in electricity, metallurgy, machinery, chemical, electron and other industries.

Construction

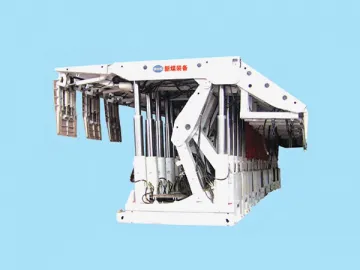

The roof ventilator is mainly comprised of the frame, flashing, guide plate, valve plate, electric opening mechanism, power-operated or hand-operated actuator, drainage channel, backplate and so on, among which the opening mechanism consists of the motor, reduction box and drive mechanism.

Advantages of the GYWT Type Roof Ventilator

1. The maximum height of the air ventilation system is only 500mm higher than the roof connector, which guarantees minimum wind resistance and avoids splicing and comprehensive leakage.

2. The roof ventilator can be directly fixed to the I-beam installed on the roof, which greatly reduces the burden on the roof and cuts installation cost.

3. Its ventilation area is quite larger than the corresponding ridge area, and the equipment allows opening and closing, which considerably eases the metal plate workload on the roof.

Structure and Size of the GYWT Type Roof Ventilator

1. With small size, this range of industrial ventilation systems can be manufactured from color plate, stainless steel or glass fiber reinforced plastics in accordance with different climate conditions.

2. Its optional bottom vent sizes involve 1.5m, 2m, 2.5m, 3m, 3.5m, 4m, 4.5m, 5m, 5.5m, 6m and so forth, and can also be customized according to your demands. The valve plate may be opened or closed by electric control or manual control.

Parameters of the GYWT Type Roof Ventilator

| No. | Model | Size of bottom vent A(mm) | Dimension and weight | Motor power ( kw/3m ) | ||

| B(mm) | H(mm) | Weight(kg /m ) | ||||

| 1 | GYWT-15 | 1500 | 2800 | 1600 | 185 | 0.37 |

| 2 | GYWT-20 | 2000 | 3800 | 2100 | 240 | 0.37 |

| 3 | GYWT-25 | 2500 | 4800 | 2400 | 295 | 0.37 |

| 4 | GYWT-30 | 3000 | 5500 | 2700 | 350 | 0.55 |

| 5 | GYWT-35 | 3500 | 6500 | 3200 | 420 | 0.55 |

| 6 | GYWT-40 | 4000 | 7500 | 3400 | 490 | 0.55 |

| 7 | GYWT-45 | 4500 | 8500 | 3600 | 560 | 0.75 |

| 8 | GYWT-50 | 5000 | 9500 | 3900 | 630 | 0.75 |

| 9 | GYWT-55 | 5500 | 10500 | 4200 | 740 | 1.1 |

| 10 | GYWT-60 | 6000 | 11500 | 4450 | 860 | 1.1 |

| 11 | GYWT-70 | 7000 | 13500 | 4500 | 900 | 2 × 0.55 |

| 12 | GYWT-80 | 8000 | 15000 | 4800 | 1000 | 2 × 0.55 |

| 13 | GYWT-90 | 9000 | 16000 | 5000 | 1200 | 2 × 0.75 |

| 14 | GYWT-100 | 10000 | 17500 | 5800 | 1500 | 2 × 0.75 |

| 15 | GYWT-120 | 12000 | 19000 | 6500 | 1900 | 2 × 0.75 |

Note: The GYWT type roof ventilator with the wind load of 1200Pa is broken down into small units with the length of 3m. Therefore, the product is comprised of 2 end units and several middle units. It voltage is 380V and the supply frequency is 50Hz.

Links:https://www.globefindpro.com/products/82089.html

-

A333 Alloy Steel Pipe

A333 Alloy Steel Pipe

-

High Density Hydraulic Prop

High Density Hydraulic Prop

-

Reducer

Reducer

-

High Pressure Spray Humidifier

High Pressure Spray Humidifier

-

Inner Injection Hydraulic Prop

Inner Injection Hydraulic Prop

-

Shale(Coal Gangue) Backfill Roof Support

Shale(Coal Gangue) Backfill Roof Support

-

Hydraulic Prop for Temporary Roof Support

Hydraulic Prop for Temporary Roof Support

-

2L Thin Coal Seam Top-Walking Roof Support

2L Thin Coal Seam Top-Walking Roof Support

-

Coupling

Coupling

-

Metal Roof Beam

Metal Roof Beam

-

Shield Roof Support

Shield Roof Support

-

2L Top-Walking Roof Support

2L Top-Walking Roof Support