Dry Steam Humidifier

1. Features of the Dry Steam Humidifier

With easy control and high regulation precision, our dry steam humidifier is able to quietly spray sterile steam without water-drop or peculiar smell. The steam may mix with air successfully.

1) The industrial steam humidifier adopts advanced steam-water separation technology to completely avoid spraying water.

2) The steam is totally separated from water.

3) The dry steam humidifier employs the high-temperature humidification method, so the humidification efficiency is as high as over 98%.

4) Its unique double-layer steam jacketed pipe helps to make sure that there is no condensate water within the sprayed steam.

5) Manufactured from stainless steel, the industrial air humidifer comes with small size, light weight, simple appearance, easy installation, corrosion resistance and long service life.

6) The dry steam humidifier can fall into the power-driven type, electromagnetic type, or combination type, which realizes the accurate remote control over humidity.

7) The special noise-elimination structure allows the industrial humidifier to effectively deaden the noise during the flow or spraying process of high-pressure steam.

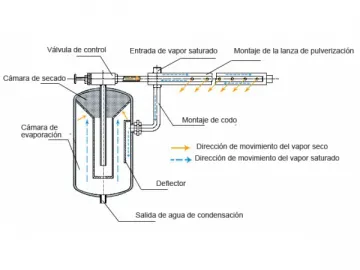

2. Working Principle of the Dry Steam Humidifier

On the basis of the advanced steam-water separation technology and mechanism, the dry steam humidifier leads the filtered saturated steam to the saturated steam inlet, and the steam may flow in an axial direction within the steam jacketed pipe. The humidification unit makes use of the latent heat of steam to heat the central spray lance, so as to spray pure dry saturated steam without condensate water.

Then, the steam enters the steam-water separation chamber with a built-in cyclic baffle plate, which makes the entered steam revolve and flow upward and vertically. In this way, the steam can be effectively separated from condensate water, and the water will be discharged from the bottom of the chamber through a steam trap. The separated steam rises and goes into the top drying chamber that is filled with threadlike stainless steel substances. Here, the residual moisture will be filtered out and noise caused by steam flow may be reduced.

Simply by opening the control valve, the dry steam humidifier will be able to realize humidification. The dry steam may enter the central spray lance and be sprayed from spray orifices with the muffler device, so as to humidify the air. To control the steam spraying quantity, the steam humidifier can be equipped with a hand-operated control valve, a solenoid valve, or an electric control valve along with an actuator.

3. Model Selection for the Dry Steam Humidifier

1) Steps

A) Look up the table to determine the model of suitable dry steam humidifier, in accordance with designed or calculated humidification amount and saturated steam pressure. Usually, the pressure value is 0.2MPa.

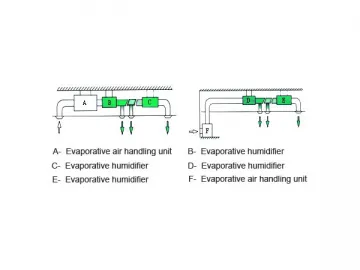

B) Choose the spray lance model according to the evaporative cooler unit or air flue width.

C) Based on the type or installation requirements of the evaporative cooler unit, decide whether to purchase the left type product or the right one.

In general, the right-type evaporative cooler unit should be equipped with a right-type dry steam humidifier, and vice versa, so as to make sure that the sprayed dry steam reverses the air flow direction.

Note: To judge whether the steam humidifier belongs to the left type or right type, please observe from its vaporizing tank to the spray lance. If the lance sprays steam towards the right, the product is left type, and vice versa.

D) Select the adjustment method in line with your control requirements.

2) Example

Known conditions: A right-type evaporative cooler unit has the air volume of 8000m3/h, the width of 1255mm, and the designed humidification amount of 95kg/h. Moreover, the saturated steam pressure on the spot is 0.2MPa.

A) Since the saturated steam pressure is 0.2MPa, and the humidification amount is 95kg/h, the 20 type dry steam humidifier is suitable whose spray orifice has the diameter of ф9.

B) You can choose L5 as the spray lance length, namely1220mm, due to the cooler width of 1255mm, which is between 1200 mm and 1310mm.

C) The right-type cooler can be applied with a right-type dry steam humidifier.

D) If you prefer the hand-operated control valve, the suitable machine model is GYQS-20- ф9-L5.

Supposing you want to remotely control the air humidifier by the 220VAC signal, please choose the GYQC-20- ф9-L5.

In case you intend to remotely open or close the control valve through the 24VAC signal, GYQD1-20- ф9-L5 is an appropriate model.

If you are able to provide 24VAC power source and 0~10VDC control signal, the GYQD2-20- ф9-L5 can be chosen to meet your demands for manufacturability or accurate remote control.

| Model Bore diameter of spray orifice Humidifying capacity (kg/h) Steam pressure (MPa) | GYQS-15 GYQD-15 GYQC-15 | GYQS-20 GYQD-20 GYQC-20 | GYQS-25 GYQD-25 GYQC-25 | GYQS-32 GYQD-32 GYQC-32 | |||||||

| ¢ 2 | ¢ 4 | ¢ 6 | ¢ 8 | ¢ 9 | ¢ 10 | ¢ 10.5 | ¢ 12 | ¢ 14 | ¢ 16 | ¢ 18 | |

| 0.02 | 1.5 | 4 | 9 | 22.5 | 27 | 34 | 40 | 55 | 75 | 145 | 187 |

| 0.1 | 2.3 | 9.4 | 21.3 | 49.5 | 62 | 75.5 | 78 | 102 | 141 | 194 | 246 |

| 0.2 | 3.6 | 14 | 35 | 68.5 | 106 | 131 | 142 | 160 | 216 | 311 | 397 |

| 0.3 | 4.5 | 18.3 | 40 | 97.5 | 152 | 187 | 205 | 217 | 293 | 448 | 569 |

| 0.4 | 6.1 | 24.5 | 58.5 | 124 | 196 | 227 | 250 | 275 | 375 | 590 | 760 |

| Note: The rated humidifying capacity in this table is calculated when the control valve is open. | |||||||||||

5. Spray Lance Parameters

| Spray lance model | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 | L10 | L11 | L12 | L13 | |

| Spray lance length | 310 | 460 | 610 | 910 | 1220 | 1500 | 1820 | 2100 | 2450 | 2740 | 3050 | 3350 | 3650 | |

| Evaporative cooler unit width (mm) | Minimum | 290 | 440 | 590 | 890 | 1200 | 1480 | 1800 | 2080 | 2430 | 2720 | 3030 | 3330 | 3630 |

| Maximum | 360 | 510 | 760 | 1060 | 1310 | 1610 | 1910 | 2080 | 2510 | 2810 | 3110 | 3410 | 3710 | |

Links:https://www.globefindpro.com/products/82107.html

-

Evaporative Humidifier

Evaporative Humidifier

-

Roof-Combined Chain Haulage Top-Walking Roof Support

Roof-Combined Chain Haulage Top-Walking Roof Support

-

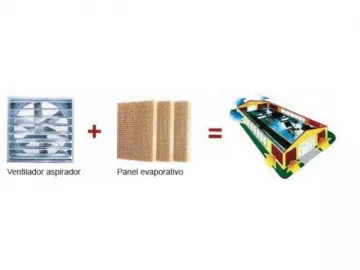

Evaporative Cooling Pad

Evaporative Cooling Pad

-

Stainless Steel Pipe

Stainless Steel Pipe

-

Solar Overheat Protector

Solar Overheat Protector

-

Custom Painted Steel Pipe

Custom Painted Steel Pipe

-

Extendable Belt Conveyor

Extendable Belt Conveyor

-

Double Loading Extendable Belt Conveyor

Double Loading Extendable Belt Conveyor

-

Exhaust Fan

Exhaust Fan

-

A213 Alloy Steel Pipe

A213 Alloy Steel Pipe

-

Top Coal Caving Roof Support

Top Coal Caving Roof Support

-

Caps

Caps