Stainless Steel Pipe

The stainless steel pipe is available in wide varieties for different purposes. Its outer diameter ranges from 0.1 to 4,500 mm and the wall thickness is 0.01 to 250 mm.

Compared with pipes made of other materials, the stainless steel pipe features large section modulus as well as high fexural strength and torsional strength. It is mainly used in the oil, construction, furniture, medical equipment, chemical engineering, aircraft and automobile manufacturing, as well as other fields.

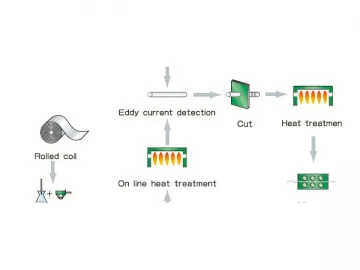

Production Process

1. Welded Pipe for Decoration

Raw materials – Slitting – Welding – Chamfering – Polishing – Inspection (Printing) – Packaging – Shipment (Warehousing)

2. Welded Pipe for Industrial Piping

Raw materials – Slitting – Welding – Heat Treatment – Correction – Alignment –Chamfering – Pickling – Inspection (Printing) – Packaging – Shipment (Warehousing)

Material Comparison Table

| Category | Material Specified by Different Standard | Standard D-SMM | Common Standard | ||

| GB China | AISI/ASTM U.S. | JISJapan | Φ(6-580)×(0.5-30)mm | GB/T 14975-2002 GB/T 14976-2002 GB 13296-91 ASTM A213/A213M JIS G3463 DIN 2462 | |

| Seamless Stainless Steel Pipe | 0Cr18Ni9 | 304/S30300 | SUS304 | ||

| 00Cr19Ni10 | 304L/S30403 | SUS304L | |||

| 0Cr25Ni20 | 310S/S31008 | SUS310S | |||

| 0Cr17Ni12Mo2 | 316/S3160 | SUS316 | |||

| 00Cr17Ni14Mo2 | 316L/31603 | SUS316L | |||

| 0Cr19Ni13Mo3 | 317/S31700 | SUS317 | |||

| 00Cr19Ni13Mo3 | 317L/S31703 | SUS317L | |||

| 1Cr18Ni9Ti | |||||

| 0Cr18Ni10Ti | 321/S32100 | SUS321 | |||

| 0Cr18Ni11Nb | 347/S34700 | SUS347 | |||

| Welded Stainless Steel Pipe | 0Cr18Ni9 | 304/S30300 | SUS304 | Φ(19-1000)×(1-20)mm | GB 12770-91 GB 12771-91 HG20537.2-92 HG20537.3-92 HG20537.4-92 ASTM A312/A312M ASTM A409/A409M JIS G3468 DIN 2463 |

| 00Cr19Ni10 | 304L/S30403 | SUS304L | |||

| 0Cr25Ni20 | 310S/S31008 | SUS310S | |||

| 0Cr17Ni12Mo2 | 316/S3160 | SUS316 | |||

| 00Cr17Ni14Mo2 | 316/LS31603 | SUS316L | |||

| 0Cr19Ni13Mo3 | 317/S31700 | SUS317 | |||

| 00Cr19Ni13Mo3 | 317L/S31703 | SUS317L | |||

| 1Cr18Ni9Ti | |||||

| 0Cr18Ni10Ti | 321/S32100 | SUS321 | |||

| 0Cr18Ni11Nb | 347/S34700 | SUS347 | |||

Physical Properties

| Type | Tensile strength | Elongation | Yield strength | Hardness | Young's modulus | Thermal conductivity | Mean coefficient of thermal expansion | |

| ASTM | JIS | Kgf/mm² (N/mm²) | % | Kgf/mm² (N/mm)² | HRB | kgf/mm² | cal/cm/sec℃ | 1/℃(-317℃) |

| TP304 | SUS304 | ≥53 (520) | ≥35 | ≥21 (≥205) | ≤90 | 1.9×104 | 0.039 | 17.8×10-6 |

| TP304L | SUS304L | ≥49 (≥480) | ≥35 | ≥18 (≥175) | ≤90 | 1.9×104 | 0.039 | 17.8×10-6 |

| TP316 | SUS316 | ≥53 (≥520) | ≥35 | ≥21 (≥205) | ≤90 | 1.9×104 | 0.039 | 17.8×10-6 |

| TP316L | SUS316L | ≥49 (≥480) | ≥35 | ≥18 (≥175) | ≤90 | 1.9×104 | 0.039 | 17.8×10-6 |

Chemical Composition

| Type | Composition (%) | |||||||||

| JIS | ASTM | C | Si | Mn | P | S | Ni | Cr | Mo | others |

| SUS304 | TP304 | ≤0.08 | ≤1.00 ≤0.75 | ≤ 2.00 | ≤ 0.040 | ≤ 0.030 | 8.00~11.00 | 18.00~20.00 | ||

| SUS304L | TP304L | ≤0.030 ≤0.035 | ≤1.00 ≤0.75 | ≤ 2.00 | ≤ 0.040 | ≤ 0.030 | 9.00~13.00 8.00~13.00 | 18.00~20.00 | ||

| SUS316 | TP316 | ≤0.08 | ≤1.00 ≤0.75 | ≤ 2.00 | ≤ 0.040 | ≤ 0.030 | 10.00~14.00 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | |

| SUS316L | TP316L | ≤0.030 ≤0.035 | ≤1.00 ≤0.75 | ≤ 2.00 | ≤ 0.040 | ≤ 0.030 | 12.00~16.00 10.00~15.00 | 16.00~18.00 | 2.00~3.00 | |

| SUS309 | TP309 | ≤0.15 | ≤1.00 ≤0.75 | ≤ 2.00 | ≤ 0.040 | ≤ 0.030 | 12.00~15.00 | 18.0~20.0 | ||

| SUS310L | TP310L | ≤0.15 | ≤1.00 | ≤ 2.00 | ≤ 0.040 | ≤ 0.030 | 19.00~22.00 | 18.0~20.0 | ||

| ≤0.75 | ||||||||||

| SUS321 | TP321 | ≤0.08 | ≤1.00 ≤0.75 | ≤ 2.00 | ≤ 0.040 | ≤ 0.030 | 9.00~13.00 | 17.00~19.00 | Ti5xc% 5xc%-0.60 | |

| SUS321H | TP321H | 0.04 -0.1 | ≤0.75 | ≤ 2.00 | ≤0.0.030≤0.040 | ≤0.030 ≤0.030 | 9.00~13.00 | 17.00~20.00 | T14xc%-0.60 | |

Related Names

Polished Stainless Steel Tube | 316 Stainless Steel Tubing | Duplex Steel Exhaust Pipe

Links:https://www.globefindpro.com/products/82111.html

-

Solar Overheat Protector

Solar Overheat Protector

-

Custom Painted Steel Pipe

Custom Painted Steel Pipe

-

Heat Exchanger Fin Tube

Heat Exchanger Fin Tube

-

High Intensity Punched Slot Screen Pipe

High Intensity Punched Slot Screen Pipe

-

Gas Generator Set

Gas Generator Set

-

3PP Coating Corrosion Resistant Steel Pipe

3PP Coating Corrosion Resistant Steel Pipe

-

Evaporative Cooling Pad

Evaporative Cooling Pad

-

Roof-Combined Chain Haulage Top-Walking Roof Support

Roof-Combined Chain Haulage Top-Walking Roof Support

-

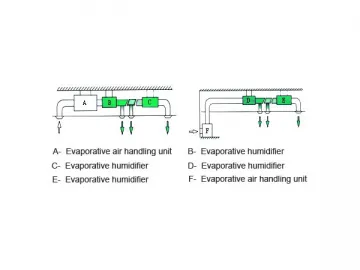

Evaporative Humidifier

Evaporative Humidifier

-

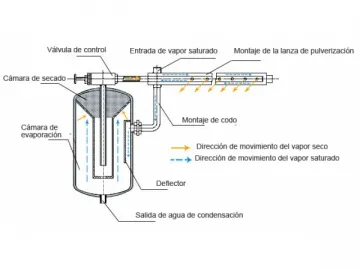

Dry Steam Humidifier

Dry Steam Humidifier

-

Extendable Belt Conveyor

Extendable Belt Conveyor

-

Double Loading Extendable Belt Conveyor

Double Loading Extendable Belt Conveyor