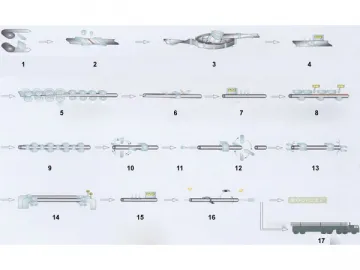

Carbon Steel ERW Pipe

The carbon steel ERW (Electric Resistance Welded) pipe differs from ordinary welded pipes in that the weld is formed by the melting of the carbon steel itself. Therefore, it has better mechanical strength than ordinary products.

Our product conforms to the standards of GB9711, API 5L, and GB3091. Its outer diameter ranges from 10 to 1860mm and its thickness is 0.5 to 40mm.

Features

1. The roll forming machine and five sizing mills greatly reduce the ovality and diameter tolerances of the product.

2. The solid-state welder imported from EFD Induction ensures no burns on both sides of the weld.

3. The 2000kW intermediate frequency heat treatment apparatus, perforated type weld polishing roller, and long-distance air cooling technology make the quality of our ERW pipes reach the leading level in the industry while ensuring that the weld and heat affected zone match the strength and toughness of the pipe body.

4. The adopted roll forming machine and weld polishing roller avoid scratching the outer surface of the product.

5. The advanced reverse molding and chamfering techniques guarantee precision pipe end bevel and blunt edge.

6. We adopt the sophisticated AS-200 ultrasonic flaw detector from abroad and the transmission part is introduced from Germany. The hydraulic test equipment is equipped with an advanced automatic imported control system and the maximum test pressure is 75MPa.

We strictly control the whole process from raw material purchasing to the production completion. Each link is under stringent inspection, so as to ensure the quality of the finished products. Also, the finished products are subjected to ray testing, ultrasonic testing, magnetic particle testing, and other tests.

Related Names

Welded Steel Pipes | ERW Steel Line Pipe | High Frequency Resistance Welded Pipe

Links:https://www.globefindpro.com/products/82121.html

-

Forged Socket Weld Flange

Forged Socket Weld Flange

-

Butt Weld Neck Flange

Butt Weld Neck Flange

-

3PE Coating Anti-Corrosion Steel Pipe

3PE Coating Anti-Corrosion Steel Pipe

-

Lap Joint Flange

Lap Joint Flange

-

Perforated Screen Pipe

Perforated Screen Pipe

-

Bend

Bend

-

A210-C Alloy Steel Pipe

A210-C Alloy Steel Pipe

-

Volvo Powered Diesel Generator Set

Volvo Powered Diesel Generator Set

-

3PP Coating Corrosion Resistant Steel Pipe

3PP Coating Corrosion Resistant Steel Pipe

-

Gas Generator Set

Gas Generator Set

-

High Intensity Punched Slot Screen Pipe

High Intensity Punched Slot Screen Pipe

-

Heat Exchanger Fin Tube

Heat Exchanger Fin Tube