Slotted Screen Pipe

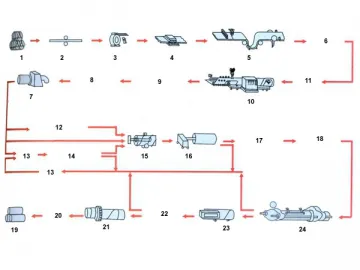

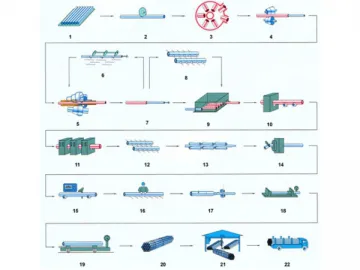

Technical Process

1. Determine the processing parameters according to the parameters of the pipe to be processed; determine the required software in line with the processing parameters.

2. Determine the matching gas index of the laser cutting equipment.

3. When the equipment meets the index requirements, start cutting operation, including:

Before processing, the pipe surface has to undergo some necessary treatments. During cutting, the pipe body is cooled to eliminate heat buildup and it is also subject to dynamic iron and oxide removal.

4. After cutting, conduct quality inspection. The substandard one is sent to the waste collection bench and the one meeting the quality requirements is ready for shipping.

Using laser can cut a slot with the width of 0.2 to 0.3 mm and such a slot can not be obtained with machine tools. Also, the phenomena like slot burst and over-burning in the process of drilling or cutting can be effectively avoided, making the defect rate of the finished slotted screen pipes less than or equal to 5%.

Features

1. The slotted screen pipe is processed from J55 or N80 oil casing. It is of high strength and not easily deformed.

2. The slot edge has good perpendicularity. It is smooth with no burr. The slots distribute uniformly.

3. The flow area is large, thus facilitating liquid flow. For a 27/8" slotted screen pipe, there are 300 slots per 1.5 meters, and the flow area is 72 mm2 per cm3 which is 2.4 times larger than that of tubing of the same specification.

4. The slotted screen pipe shows more apparent superiority when used in an inclined or horizontal well.

5. The product has gone through anti-corrosion treatment. A dense protective layer has formed on the product surface, which improves the corrosion resistance and wear resistance, thus prolonging the service life of the product.

6. Easy to use, this product is suitable for use in wells containing sand with the particle size greater than 0.3mm.

7. With large inner diameter, the product is easy for nesting.

Main Technical Parameters

Pipe category: Oil casing or tubing

Length: ≤15m

Outer diameter: 50~500mm

Wall thickness: ≤20mm

Slot width: (0.10~4)mm±0.03mm

Slot quantity: Arbitrary value

Slot arrangement: Parallel, staggered, spiral

Slot spacing: Random

Mechanical Properties

| API standard casing | Inner diameter mm | Length mm | Slot length mm | Slot density /m | Slot width mm | Slot width accuracy | Effective filtration area cm/m | Maximum tensile load kN | ||

| Specification mm | Wall thickness mm | Weight per meter kg/m | ||||||||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 | 512.54 |

| 73.02 | 5.5 | 9.15 | 62 | 3 | 80 | 240 | 0.3 | ±50 | 57.6 | 688.55 |

| 88.9 | 6.5 | 13.22 | 75.9 | 3 | 80 | 280 | 0.3 | ±50 | 67.2 | 995.1 |

| 101.6 | 6.5 | 15.22 | 88.6 | 3 | 80 | 300 | 0.3 | ±50 | 72 | 1151.2 |

| 114.3 | 7 | 18.47 | 100.3 | 10 | 80 | 320 | 0.3 | ±50 | 76.8 | 1400.4 |

| 127 | 7.52 | 22.13 | 112 | 10 | 80 | 340 | 0.3 | ±50 | 81.6 | 1673.8 |

| 139.7 | 7.72 | 25.11 | 124.3 | 10 | 80 | 360 | 0.3 | ±50 | 86.4 | 1900.2 |

| 9.17 | 29.48 | 121.4 | 10 | 80 | 360 | 0.3 | ±50 | 86.4 | 2232.4 | |

| 168.3 | 8.94 | 35.09 | 150.4 | 10 | 80 | 400 | 0.3 | ±50 | 96 | 2672.95 |

| 177.8 | 8.05 | 33.68 | 161.7 | 10 | 80 | 440 | 0.3 | ±50 | 105.6 | 2559.2 |

| 9.19 | 38.19 | 159.4 | 10 | 80 | 440 | 0.3 | ±50 | 105.6 | 2940.7 | |

Related Names

Oil And Gas Well Screen | Oblong Slotted Steel Pipe | Sieve Pipe

Links:https://www.globefindpro.com/products/82137.html