Carbon Steel Seamless Pipe

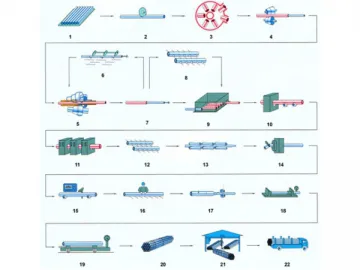

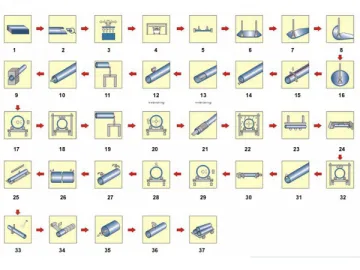

The carbon steel seamless pipe is produced by rolling, drawing, squeezing, and punching. As its name suggests, it has no seams on the surface. Compared with solid steel, steel pipe is lighter under the same compressive strength and tensile strength. Therefore, it is widely used in oil, chemical, shipping, automobile, aviation, energy, construction, military, and other industries.

Common technical standards: ASTM A106 Grade B, ASTM A53 Grade B, API 5L Grade BProduct specification: Φ(17-720)mm×(2-70)mm

The ASTM A106 Grade B and ASTM A53 Grade B are the most commonly used American standards for carbon steel seamless pipe. They are applicable to pipes for high temperature services as well as pipes operating below 350℃ for pressure piping, pipeline and general purposes. Products conforming to ASTM A106 are processed by cold drawing or hot rolling.

ASTM A53

| Standard | Grade | Chemical Composition | Mechanical Properties | |||||||||||

| C | Si | Mn | P | S | Cu | Ni | Mo | Cr | V | Tensile Strength | Yield Strength | Elongation | ||

| ASTM A53 | A | ≤ 0.25 | / | ≤ 0.95 | ≤ 0.05 | ≤ 0.06 | ≤ 0.40 | ≤ 0.40 | ≤ 0.15 | ≤ 0.40 | ≤ 0.08 | ≥ 330 | ≥ 205 | ≥ 29.5 |

| B | ≤ 0.30 | / | ≤ 1.2 | ≤ 0.05 | ≤ 0.06 | ≤ 0.40 | ≤ 0.40 | ≤ 0.15 | ≤ 0.40 | ≤ 0.08 | ≥ 415 | ≥ 240 | ≥ 29.5 | |

ASTM A106

| Standard | Grade | Chemical Composition | Mechanical Properties | |||||||||||

| C | Si | Mn | P | S | Cu | Ni | Mo | Cr | V | Tensile Strength | Yield Strength | Elongation | ||

| ASTM A106 | B | ≤ 0.30 | ≥ 0.10 | 0.29- 1.06 | ≤ 0.035 | ≤ 0.035 | ≤ 0.40 | ≤ 0.40 | ≤ 0.15 | ≤ 0.40 | ≤ 0.08 | ≥ 415 | ≥ 240 | ≥ 30 |

| C | ≤ 0.35 | ≥ 0.10 | 0.29- 1.06 | ≤ 0.035 | ≤ 0.035 | ≤ 0.40 | ≤ 0.40 | ≤ 0.15 | ≤ 0.40 | ≤ 0.08 | ≥ 485 | ≥ 275 | ≥ 30 | |

API 5L PSL1

| Grade and Category | Chemical Composition | Mechanical Properties | ||||||

| C (Max.) | Mn (Max.) | P (Max.) | S (Max.) | Tensile Strength | Yield Strength | |||

| PSI | MPa | PSI | MPa | |||||

| A | 0.22 | 0.90 | 0.030 | 0.030 | 48000 | 331 | 30000 | 207 |

| B | 0.28 | 1.20 | 0.030 | 0.030 | 60000 | 414 | 35000 | 241 |

| X42 | 0.28 | 1.30 | 0.030 | 0.030 | 60000 | 414 | 42000 | 290 |

| X46 | 0.28 | 1.40 | 0.030 | 0.030 | 63000 | 434 | 46000 | 317 |

| X52 | 0.28 | 1.40 | 0.030 | 0.030 | 66000 | 455 | 52000 | 359 |

| X56 | 0.28 | 1.40 | 0.030 | 0.030 | 71000 | 490 | 56000 | 386 |

| X60 | 0.28 | 1.40 | 0.030 | 0.030 | 75000 | 517 | 60000 | 414 |

| X65 | 0.28 | 1.40 | 0.030 | 0.030 | 77000 | 531 | 65000 | 448 |

| X70 | 0.28 | 1.40 | 0.030 | 0.030 | 82000 | 565 | 70000 | 483 |

API 5L is a standard for line pipe which is used to transport oil, gas, and water extracted from the ground to oil and gas industry enterprises, including seamless type and welded type. Its end is plain, threaded, or belled, and the connection mode is correspondingly welding, coupling, and socket connection. Steel grade ranges from X42 to X70. There are onshore pipeline and submarine pipeline in variety.

API 5L PSL2

| Grade and Category | Chemical Composition | Mechanical Properties | Mechanical Properties | |||||||||

| C (Max.) | Mn (Max.) | P (Max.) | S (Max.) | Tensile Strength | Tensile Strength | Yield Strength | Yield Strength | |||||

| PSI | MPa | PSI | MPa | PSI | MPa | PSI | MPa | |||||

| B | 0.24 | 1.20 | 0.025 | 0.015 | 60000 | 414 | 11000 | 758 | 35000 | 241 | 65000 | 758 |

| X42 | 0.24 | 1.30 | 0.025 | 0.015 | 60000 | 414 | 11000 | 758 | 42000 | 290 | 72000 | 758 |

| X46 | 0.24 | 1.40 | 0.025 | 0.015 | 63000 | 434 | 11000 | 758 | 46000 | 317 | 76000 | 758 |

| X52 | 0.24 | 1.40 | 0.025 | 0.015 | 66000 | 455 | 11000 | 758 | 52000 | 359 | 77000 | 758 |

| X56 | 0.24 | 1.40 | 0.025 | 0.015 | 71000 | 490 | 11000 | 758 | 56000 | 386 | 79000 | 758 |

| X60 | 0.24 | 1.40 | 0.025 | 0.015 | 75000 | 517 | 11000 | 758 | 60000 | 414 | 82000 | 758 |

| X65 | 0.24 | 1.40 | 0.025 | 0.015 | 77000 | 531 | 11000 | 758 | 65000 | 448 | 87000 | 758 |

| X70 | 0.24 | 1.40 | 0.025 | 0.015 | 82000 | 565 | 11000 | 758 | 70000 | 483 | 90000 | 758 |

NACE MR0175 is a standard for materials for use in H2S-containing environments in oil and gas production. It is internationally regulated that when the partial pressure of H2S reaches 300Pa, the pipe used should be resistant to acid corrosion. Pipelines used under this condition have special requirements on the carbon content, sulfur content, phosphorus content, calcium sulfur ratio, and flaw detection. Hydrogen induced cracking test and sulfide stress cracking test are required.

We are one of the few manufacturers in China that are able to provide line pipes conforming to both API 5L PSL2 and NACE MR0175. We accept testing from the customer or the third-party testing company.

In addition to the aforementioned carbon steel seamless pipes, our company is also able to produce products meeting the following American standards.

1. ASTM A179 Standard Specification for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes

Outer diameter range: 3.2-76.2mm

2. ASTM A192 Standard Specification for Seamless Carbon Steel Boiler Tubes for High-Pressure Service

Nominal diameter: 12.7-177.8mm

Thickness: 2.2-25.4mm

3. ASTM A210/A210M-2003 Standard Specification for Seamless Medium-Carbon Steel Boiler and Superheater Tubes

4. ASTM A178/A178M-2002 Standard Specification for Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes

Outer diameter: 12.7-127mm

Wall thickness: 0.9-9.1mm

Related Names

Seamless Steel Pipe Manufacturer | Black Steel Tubes | Metal Tubing Supply

Links:https://www.globefindpro.com/products/82143.html

-

Carbon Steel LSAW Pipe

Carbon Steel LSAW Pipe

-

Lovol Powered Diesel Generator Set

Lovol Powered Diesel Generator Set

-

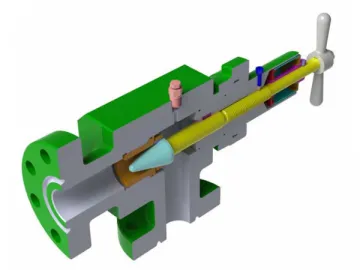

Orifice Control Choke Valve

Orifice Control Choke Valve

-

H2 Adjustable Choke Valve

H2 Adjustable Choke Valve

-

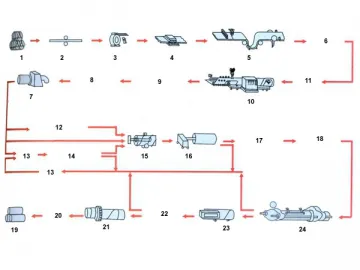

PFK Manual Gate Valve (Expanding Gate Valve)

PFK Manual Gate Valve (Expanding Gate Valve)

-

FC Manual Gate Valve

FC Manual Gate Valve

-

Epoxy Coating Steel Pipe

Epoxy Coating Steel Pipe

-

Carbon Steel SSAW Pipe

Carbon Steel SSAW Pipe

-

3PP Coating Corrosion Resistant Steel Pipe

3PP Coating Corrosion Resistant Steel Pipe

-

Elbow

Elbow

-

A335 Alloy Steel Pipe

A335 Alloy Steel Pipe

-

Slotted Screen Pipe

Slotted Screen Pipe