Carbon Steel LSAW Pipe

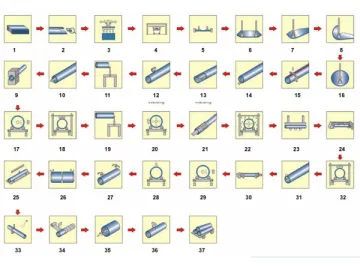

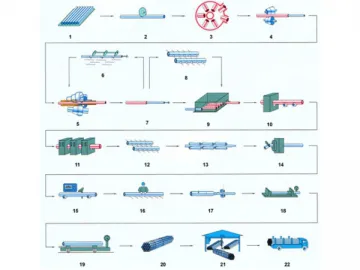

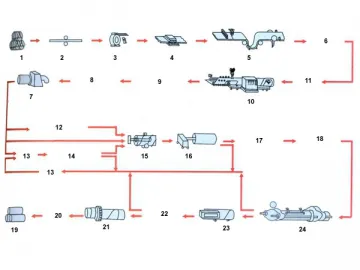

The production process of the carbon steel LSAW pipe is described below. A single steel plate of moderate thickness is firstly pressed or rolled into billet in the mold or molding machine. The billet is then welded by the double-sided longitudinal submerged arc welding method and subjected to diameter enlargement to form the LSAW pipe.

This product boasts excellent weld toughness, ductility, uniformity and compactness. It also has advantages of large diameter, thick wall, high pressure resistance, low temperature resistance, and strong corrosion resistance, widely used for transmitting oil and gas. According to API standards, when the large oil and gas pipelines have to pass through the alpine region, seabed or densely populated areas, the LSAW pipe is the only applicable one.

1. Authentication Certificates

CE, ISO9001, ISO14001, OHSAS 18001

2. Product Specification

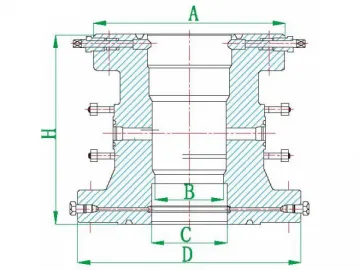

Diameter: 426-1422.4mm (16-56in)

Length: 3-12.3m

Wall thickness: 8-50mm for pipes made of common or low carbon alloy

8-26.4mm (0.315-1.04in) for pipes made of pipeline steel with grade above X70

3. Standards Compliant

API 5L PSL2, API Spec 2B, GB/T9711, ISO3183

4. Application

The carbon steel LSAW pipe is mainly used to transmit oil gas, coal slurry, ore pulp, and other media on land or in the sea. It is also used for structural purposes in the offshore platforms, power plants, and urban construction.

5. Main Features

a. Due to the adoption of prewelding and subsequent precision welding, the welding process is stable and the weld has desirable properties.

b. Compared with welded pipes with non-straight seams, the longitudinal submerged arc welded pipe has shorter welded seams, thus leading to small probability of welding defects.

c. It is easy to conduct nondestructive testing for the welded seam during production and nondestructive testing review during use in the wild.

d. Our product boasts small and uniformly distributed internal stress, so stress corrosion cracking is eliminated.

e. With size of high precision, the product is easy to construct on site.

f. This product is available in a variety of specifications.

6. Quality Inspection

Our company implements strict quality supervision system and resolutely carries out the guideline of no delivery with defectiveness. Before leaving the factory, our products are subject to visual inspection, ultrasonic flaw detector, X-ray inspection, and hydrostatic testing. In addition, we accept on-site supervision and inspection by the customer or third-party testing company.

Related Names

Thin Wall Steel Pipe | Longitudinal Welded Steel Pipe | Large Diameter Steel Pipe

Links:https://www.globefindpro.com/products/82144.html

-

Lovol Powered Diesel Generator Set

Lovol Powered Diesel Generator Set

-

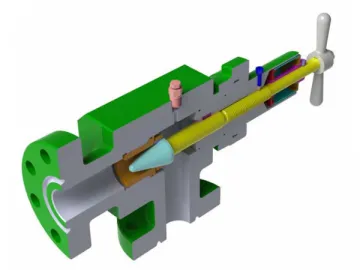

Orifice Control Choke Valve

Orifice Control Choke Valve

-

H2 Adjustable Choke Valve

H2 Adjustable Choke Valve

-

PFK Manual Gate Valve (Expanding Gate Valve)

PFK Manual Gate Valve (Expanding Gate Valve)

-

FC Manual Gate Valve

FC Manual Gate Valve

-

Tubing Head

Tubing Head

-

Carbon Steel Seamless Pipe

Carbon Steel Seamless Pipe

-

Epoxy Coating Steel Pipe

Epoxy Coating Steel Pipe

-

Carbon Steel SSAW Pipe

Carbon Steel SSAW Pipe

-

3PP Coating Corrosion Resistant Steel Pipe

3PP Coating Corrosion Resistant Steel Pipe

-

Elbow

Elbow

-

A335 Alloy Steel Pipe

A335 Alloy Steel Pipe