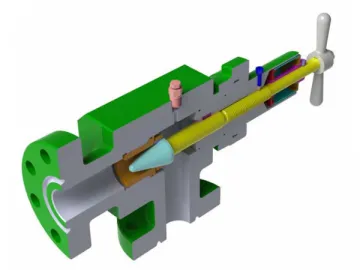

Orifice Control Choke Valve

Overall Descriptions

1. The orifice control choke valve is a fixed or adjustable throttle for long-term use. It is equipped with a standalone cover so that the stem can completely exit from the corrosive channel. This extends the stem life and enhances the controllability.

2. Different from the H2 positive and adjustable throttles, it adopts two pieces of rotated hard alloy plates for flow regulation. The plates can be designed with open holes of different specifications upon the actual needs, so the optimal and maximal throttling diameter can be reached.

3. Except the high-rigidity hard alloy plate and seat, the orifice control choke valve is also inlaid with hard alloy cover inside the outlet. Thus, the possibility of body damage caused by fluid erosion is greatly reduced, and the product life is prolonged.

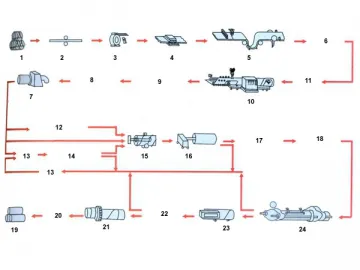

Classification

It is classified into the manual type and the hydraulic type to satisfy the requirements of customers and different field conditions. Besides, the hydraulic type can be optionally configured with a hydraulic control box.

Parameters

1. Standard size: 1 13/16" , 2 1/16" -7 1/16"

2. Maximum throttling diameter of needle and seat: 1" , 2" , 3"

3. Fixed oil nipple size: 1/8" , 3/16" -128/64"

4. Working pressure: 2000-15000PSI

5. Working temperature: API rated grade K, L, P, R, S, T, U, X, -75°F- 350°F (-59°C- 177°C)

6. Material of orifice control choke valve: API rated grade AA, BB, CC, DD, EE, FF

Materials of Needle and Seat

1. Standard: High-frequency quenched stainless steel

2. High-grade: Abrasion-resistant stainless steel with tungsten carbide

3. Super-grade: Tungsten carbide needle head

Materials of Oil Nipple

1. Standard: High-frequency quenched stainless steel

2. High-grade: Stainless steel oil nipple body, fixed hole cover inlaid with tungsten carbide

Related Names

Fluid Reducing Valve | Hydraulic Choke Valve | Adjustable Orifice Valve

Links:https://www.globefindpro.com/products/82146.html

-

H2 Adjustable Choke Valve

H2 Adjustable Choke Valve

-

PFK Manual Gate Valve (Expanding Gate Valve)

PFK Manual Gate Valve (Expanding Gate Valve)

-

FC Manual Gate Valve

FC Manual Gate Valve

-

Tubing Head

Tubing Head

-

Shangchai Powered Diesel Generator Set

Shangchai Powered Diesel Generator Set

-

Containerised Generator Set

Containerised Generator Set

-

Lovol Powered Diesel Generator Set

Lovol Powered Diesel Generator Set

-

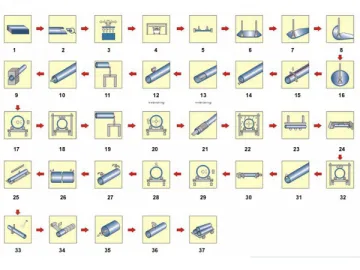

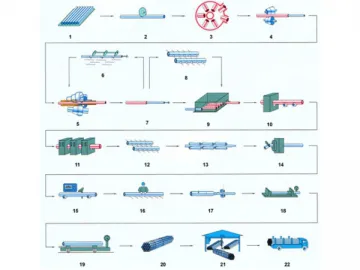

Carbon Steel LSAW Pipe

Carbon Steel LSAW Pipe

-

Carbon Steel Seamless Pipe

Carbon Steel Seamless Pipe

-

Epoxy Coating Steel Pipe

Epoxy Coating Steel Pipe

-

Carbon Steel SSAW Pipe

Carbon Steel SSAW Pipe

-

3PP Coating Corrosion Resistant Steel Pipe

3PP Coating Corrosion Resistant Steel Pipe