Casing Hanger

Generally, the casing hanger is classified into two types, i.e. the slip type and the mandrel type. In addition, the slip type is also divided into the WD type, C-21 type, C-22 type and the C-29 type. Surely, this product can be flexibly customized according to your actual requirements and the specific working conditions.

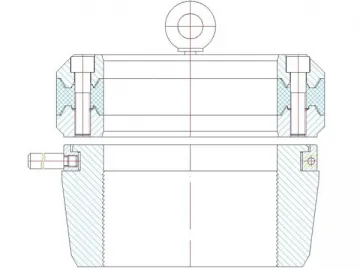

WD Type

Through manually operating the slip for locking the surface casing, the WD type suspensor is used for bottom connection of casing head, suitable for various casing pipes.

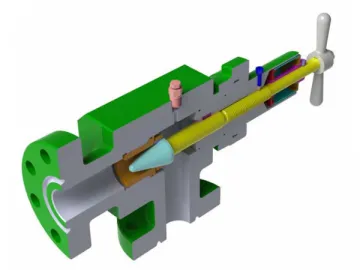

C-21 Type

This product can be split. It adopts manually-operated rubber seal incitation and comes with H type packer seal for reliable sealing when the casing pipe is suspended or switched off. It is fit for surface casings or casings used for returning the well cementing slurry. Besides, the C-21 casing hanger is applicable for various casing programs.

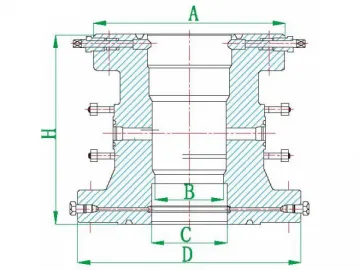

C-22 Type

It is in annular shape and composed of the packer seal, slip and the supporting bowl. It is also detachable. After the casing pipe is hung, the packer seal below the slip will automatically seal the casing pipe under the gravity of casing string. It maximally lessens the declination of casing pipes by controlling the friction force. Additionally, it is also very economical and featured by easy installation.

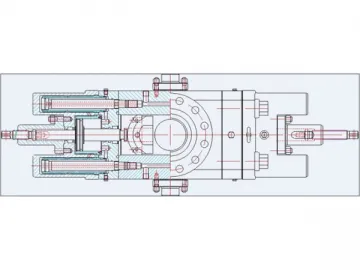

C-29 Type

Compared with the common types, the C-29 casing hanger is more advanced for it has large bearing capacity but less casing pipe declination. When the top slip moves downward and imposes pressure towards packer seal, the lower slip can automatically mesh and control the compression. As the lower slip does not move with the casing pipe, it won’t produce overlarge compression as the common tapered slip.

Applications

This product is applicable for pressure testing in various casing programs.

Basic Parameters

1. Test pressure: The test pressure applicable to various casing programs is the minimum valve between the two pressure values, i.e. 80% of anti-collapse pressure and the working pressure.

2. Working medium: Petroleum, natural gas, slurry (including H2S and CO2)

3. Working temperature: -46°C-121°C (LU Grade)

4. Standard level: PSL1-4

5. Performance level: PR1-2

| Size Tbg. (inch) | Size Nom. (inch) | |||||

| 9 | 11 | 13 5/8 | 16 3/4 | 20 3/4 | 21 1/4 | |

| 5 | ||||||

| 5 1/2 | ||||||

| 6 5/8 | ||||||

| 7 | ||||||

| 7 5/8 | ||||||

| 8 5/8 | ||||||

| 9 5/8 | ||||||

| 10 3/4 | ||||||

| 11 3/4 | ||||||

| 12 3/4 | ||||||

| 13 3/8 | ||||||

| 16 | ||||||

Related Names

Slip and Seal Casing Hanger | Wellbore Casing Assembly | Oil Well Completion Tool

Links:https://www.globefindpro.com/products/82153.html

-

Deutz Powered Diesel Generator Set

Deutz Powered Diesel Generator Set

-

Casing Head

Casing Head

-

Yuchai Powered Diesel Generator Set

Yuchai Powered Diesel Generator Set

-

MS Check Valve

MS Check Valve

-

Manifold

Manifold

-

BOP (Blowout Preventer)

BOP (Blowout Preventer)

-

Containerised Generator Set

Containerised Generator Set

-

Shangchai Powered Diesel Generator Set

Shangchai Powered Diesel Generator Set

-

Tubing Head

Tubing Head

-

FC Manual Gate Valve

FC Manual Gate Valve

-

PFK Manual Gate Valve (Expanding Gate Valve)

PFK Manual Gate Valve (Expanding Gate Valve)

-

H2 Adjustable Choke Valve

H2 Adjustable Choke Valve