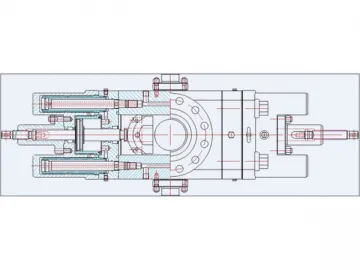

BOP (Blowout Preventer)

The BOP (blowout preventer) is frequently used for well tests, well repairs, well completion and other operations. Integrating complete sealing and semi-sealing functions, it can effectively avoid well blowout accidents, and boasts the advantages as simple structure, easy operation and high-pressure resistance. It has been an indispensable safety sealing device for oil fields.

During petroleum drilling, this product is installed on the casing pipe head for controlling the blowout of high-pressure oil, water and gas. When the oleo-pneumatic pressure inside the well is very high, the BOP will seal up the well head. When the heavy slurry is pressed into the well via the drill pipe, the spool below the ram will replace the gas cut slurry and increase the pressure of liquid column inside the well to withhold the blowout of high-pressure oil gas.

Classification

This product is classified into many types, such as the U type, annular type, rotary type, etc.

U Type

It is mainly applied to land and ocean platforms. Designed in ram style, it boasts a wide range of specifications. The ram is used for pressure burdening. The wellhead pressure acting on the ram increases the sealing force and maintains sealing under the circumstance of hydraulic loss. Hence, the overall performance is improved. Besides, the U type BOP comes with the following features.

1. The large tension of hydraulic bolt ensures the continuous accuracy and stability of bolt load.

2. Due to the sealed valve cover, the back-up ring doesn’t have to produce large torque during the installation of bolts and nuts.

3. This product is designed with a hydraulically operated locking mechanism. Thanks to the wedge-type lock, the ram can still be tightly closed under pressure. Besides, the operation system can be interlocked via the program to guarantee that the wedge-type lock can be returned before this product is opened.

4. For offshore operation, the pressure equalizing chamber and the wedge-type lock are used together for eliminating the possibility that the wedge-type lock is opened because of hydraulic and static water pressure.

5. In addition, the U type BOP comes with a forged body and the ram is provided in multiple types for your option.

6. For the products from 7" to 13", the working pressure can range from 5000PSI to 15000PSI.

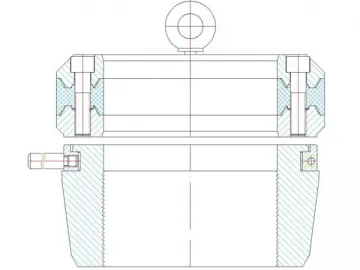

Annular Type

This product is often provided with a large gate and a sealed annular space between the pipe column and the shaft will be formed during operation. Even under the condition that there is no pipe column, this BOP can also independently accomplish well sealing. However, it is not recommended for long-term use.

Rotary Type

This product is applicable when blowout occurs during drilling.

Related Names

Double Ram Workover BOP | Annular Blowout Preventer | Oil Well Servicing Tool

Links:https://www.globefindpro.com/products/82159.html

-

Tubing Hanger

Tubing Hanger

-

Cummins Powered Diesel Generator Set

Cummins Powered Diesel Generator Set

-

Steyr Powered Diesel Generator Set

Steyr Powered Diesel Generator Set

-

Doosan Powered Diesel Generator Set

Doosan Powered Diesel Generator Set

-

Silent Generator Set

Silent Generator Set

-

Perkins Powered Diesel Generator Set

Perkins Powered Diesel Generator Set

-

Manifold

Manifold

-

MS Check Valve

MS Check Valve

-

Yuchai Powered Diesel Generator Set

Yuchai Powered Diesel Generator Set

-

Casing Head

Casing Head

-

Deutz Powered Diesel Generator Set

Deutz Powered Diesel Generator Set

-

Casing Hanger

Casing Hanger